Pantoea sp, M3, and method for degrading malachite green

A technology of Malachite Green and Pantoea, which is applied in the direction of chemical instruments and methods, applications, bacteria, etc., can solve the problems of low accuracy and no simultaneous detection of LMG, and achieve convenient use, stable degradation performance, and easy handling effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take an appropriate amount of fish pond bottom sludge and inoculate it into the enrichment medium containing 0.04mg / L MG, and cultivate in the dark at 30°C and 150rpm. After the culture medium is turbid and the color turns lighter, transfer the suspension to the next batch of fresh culture medium, and gradually increase the concentration of MG, and repeat this until the concentration of MG reaches 5 mg / L. The mixed culture obtained after acclimatization was isolated and purified by plate coating of enriched medium, and the MG-degrading strain M3 was finally screened.

Embodiment 2

[0034] The strain was inoculated in 5mg / L malachite green enrichment medium, activated to the logarithmic phase, and the medium composition was calculated as mg / L: glucose 1000; NaCl 10; MgSO 4 10; NH 4 NO 3 100;K 2 HPO 4 100; KH 2 PO 4 100; yeast extract 60; pH 7.0. Put the obtained bacterial solution into the malachite green medium containing 0.5-5 mg / L malachite green at a concentration of 2%-4% by weight, and measure the degradation rate after culturing for 5 days, which can reach 97.54%, 97.1%, and 100% respectively and 77.8%, it can be seen that the degradation effect of the bacteria on malachite green, especially the lower concentration of malachite green is better.

Embodiment 3

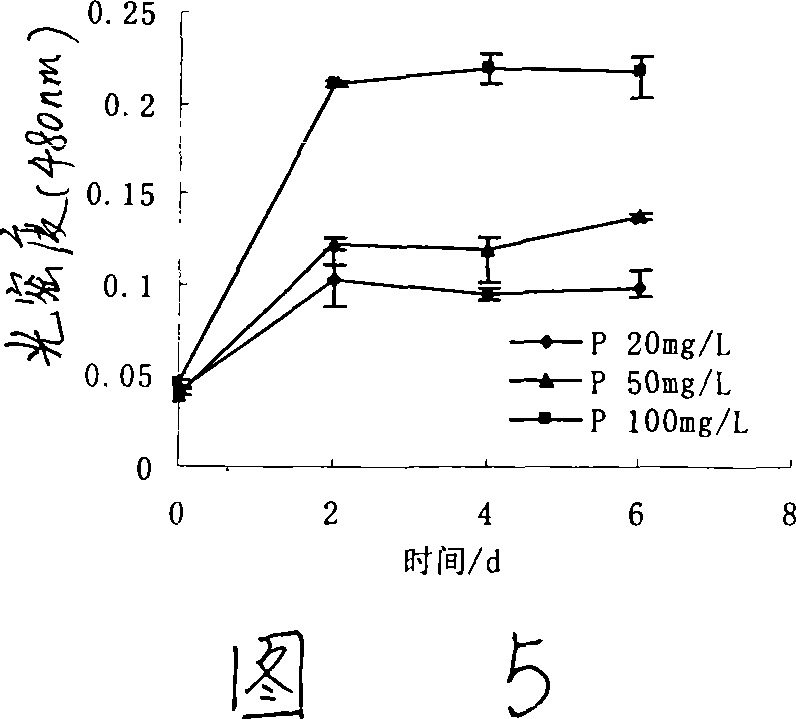

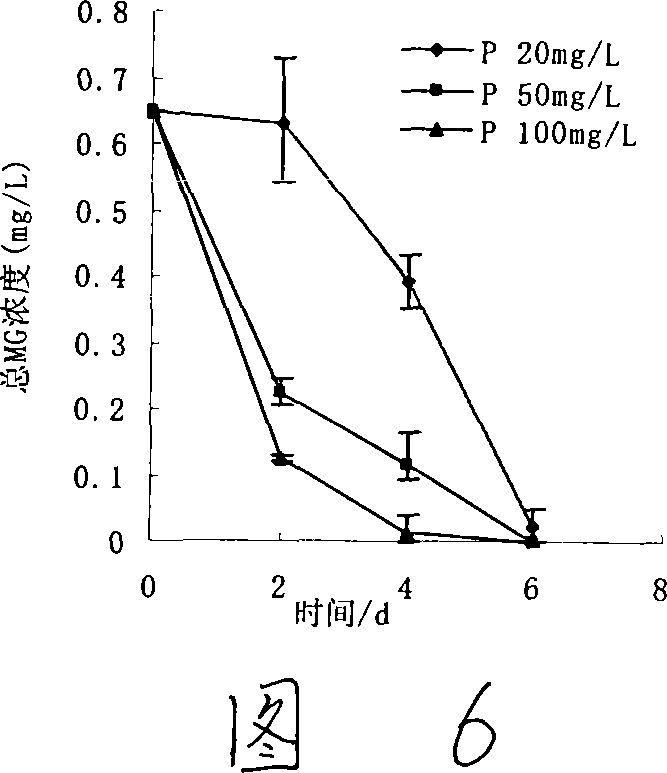

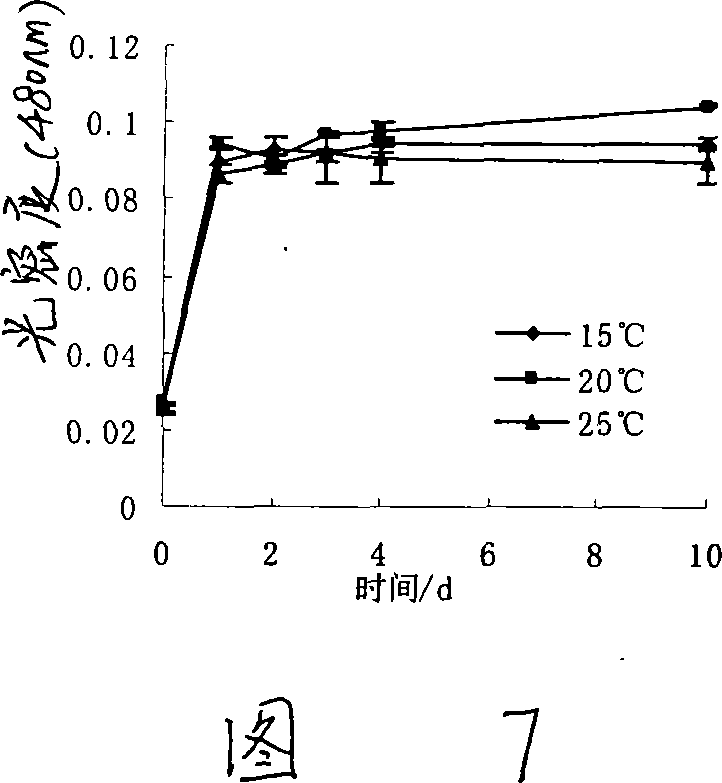

[0036]Different glucose concentrations were set in the degradation system to compare the degradation effect of MG (Figure 1 and Figure 2). It can be seen from Figure 1 and Figure 2 that when the glucose concentration is 0mg / L, M3 grows slowly, and the MG concentration does not decrease significantly after 10 days of culture, indicating that M3 cannot grow and metabolize with MG as the only carbon source, and its slow growth and Degradation may occur due to the influence of the initially introduced bacterial suspension. At higher glucose concentrations of 500mg / L and 1000mg / L, the degradation rate of MG was basically the same as the growth of the strain. The strain reached the stable growth phase within 1d, and could degrade MG almost completely within 2d. Therefore, glucose is used as the carbon source of the growth substrate of the strain, and its concentration has a certain influence on the growth of microorganisms. The higher the concentration, the faster the growth of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com