Production apparatus for culturing tiny alga and production method

A production device and production method technology, applied in enzymology/microbiology devices, biochemical cleaning devices, biochemical equipment and methods, etc., can solve problems such as pollution, climatic conditions, and easy biological pollution, and reduce production Low cost, scientific and reasonable design, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

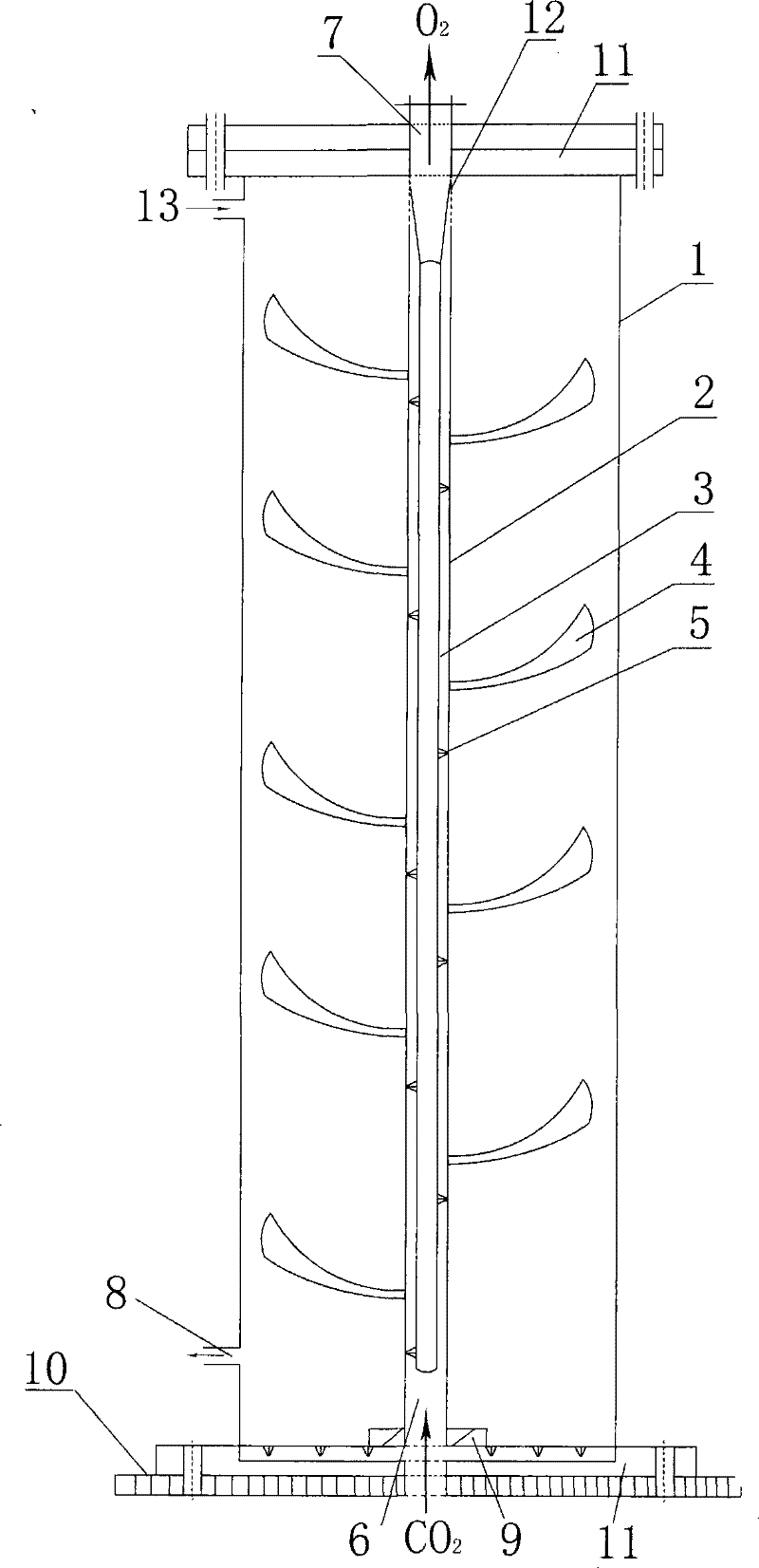

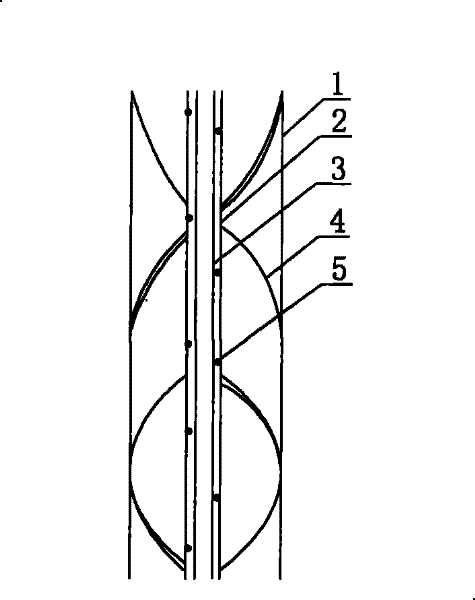

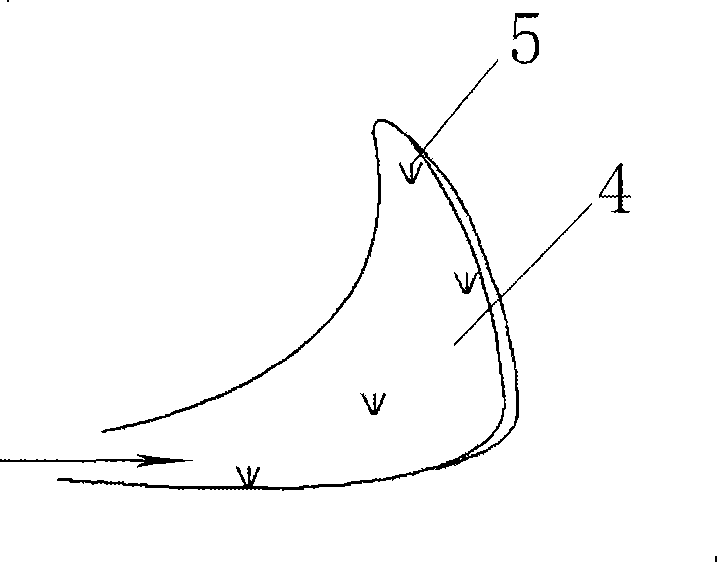

[0027] The production device for cultivating microalgae is a reactor unit device for cultivating microalgae. The reactor adopts a transparent polyethylene cylindrical reactor 1 with a flange, a true diameter of 80 cm, and a height of 2.5 meters. It is fixed on the ground base 10 through a flange 11 . In the central axis area of the reactor, there are such figure 1 The paddle-type guide vane static mixer 2 shown has 8 paddle-type guide vanes 4, which are hollow and equipped with micro-nozzles, which are alternately fitted on the central hollow tube, and the central hollow tube is provided with an illumination device 3 , CO 2 Exit nozzles (single question) 5, alternately arranged on the central empty pipe, blades and bottom, and the top of the central empty pipe is equipped with oxygen and CO 2 The channel port 12 communicates with the top oxygen outlet 7, and the bottom is CO 2 An air inlet 6, an electromagnetic oscillator 9 is installed in the reactor at the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com