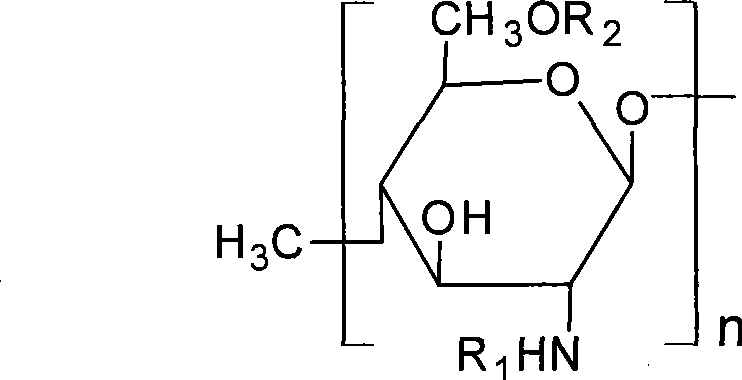

Method for synthesizing polymer of amphoteric chitosan

A technology of chitosan polymer and synthesis method, applied in the field of analytical biology, can solve the problem of single performance of chitosan derivatives, and achieve the effect of wide application range and improved pH value stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation method of amphoteric chitosan polymer of the present invention adopts following processing steps:

[0019] 100g degree of deacetylation is dissolved in 90% chitosan in 1000ml 5% acetic acid solution, and dissolves into chitosan solution while stirring. Pass N at 90°C 2 Add 0.5mmol / L initiator cerium ammonium nitrate solution and DMDAAC aqueous solution 20g successively under gas and stirring conditions, and react for 3h to obtain cerium ammonium nitrate solution. The cerium ammonium nitrate solution obtained above was cooled at 40°C, precipitated with 70% ethanol, washed with methanol for 3 times, filtered with a vacuum pump, and dried in vacuo to obtain a crude product, then the crude product was extracted with 50ml of acetone in a Soxhlet extractor After extracting for 6 hours to remove the homopolymer, dry for 10 hours at 70° C. and a vacuum of 0.5 MPa to obtain quaternized chitosan. Add 100 g of quaternized chitosan to 1000 ml of isopropanol as a s...

Embodiment 2

[0023] The preparation method of amphoteric chitosan polymer of the present invention adopts following processing steps:

[0024] 100g degree of deacetylation is dissolved in 90% chitosan in 1000ml 8% acetic acid solution, dissolve while stirring, and pass N at 90°C 2 Add 0.7mmol / L initiator cerium ammonium nitrate solution and 60 g of DMDAAC aqueous solution successively under gas and stirring conditions, and react for 7 hours to obtain cerium ammonium nitrate solution. The cerium ammonium nitrate solution obtained above was cooled at 45°C, precipitated with 80% ethanol, washed with methanol for 4 times, filtered with a vacuum pump, and dried in a vacuum to obtain a crude product, which was then extracted with acetone in a Soxhlet extractor. After removing the homopolymer by extraction for 14 hours, dry it for 12 hours at 80° C. and a vacuum of 0.8 MPa to obtain quaternized chitosan. Add 100 g of quaternized chitosan to 1000 ml of isopropanol as a solvent, add 40% sodium hyd...

Embodiment 3

[0026] The preparation method of amphoteric chitosan polymer of the present invention adopts following processing steps:

[0027] 100g degree of deacetylation is dissolved in 90% chitosan in 1000ml 10% acetic acid solution, dissolve while stirring, and pass N at 90°C 2 Add 1.0 mmol / L initiator cerium ammonium nitrate solution and 100 g of DMDAAC aqueous solution successively under gas and stirring conditions, and react for 10 h to obtain cerium ammonium nitrate solution. Cool at 50°C, precipitate with 80% ethanol, wash with methanol for 5 times, filter with a vacuum pump, and dry in a vacuum to obtain a crude product, then extract the crude product with acetone in a Soxhlet extractor for 20 hours to remove the homopolymer Finally, dry at 100° C. for 15 hours under the condition of a vacuum of 1.0 MPa to obtain quaternized chitosan. 100g of quaternized chitosan is added to 1000ml of solvent isopropanol, and a concentration of 50% sodium hydroxide is added, and alkalized at 60°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com