Anti-thrombocyte tetratitanate-NB06 and its application

An anti-platelet, peptide compound technology, applied in the field of medicine and biology, can solve problems such as no reports, and achieve the effect of improving anti-platelet aggregation activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

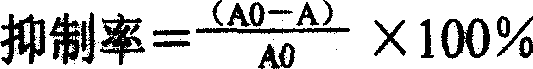

Method used

Image

Examples

Embodiment 1

[0020] : The solid-phase synthesis of NB06

[0021] Weigh 76mg of Rink Amide MBHA resin (0.55mM / g load), swell with dichloromethane in the polypeptide reaction bottle for 1 hour, remove the dichloromethane by suction filtration; add 5 ml of 20% pyridine / dimethylformamide , shake and mix at room temperature for 10 minutes to remove the Fmoe protective group; remove the deprotection solution by suction filtration, and repeat the deprotection once; weigh 5 times excess Fmoc-protected tryptophan and dissolve it in 1ml (or 0.5ml) of 2M DIEA , add a 5-fold excess of 0.5M HBTU / HoBT, mix well, and activate at room temperature for 10 minutes; transfer the activated protected amino acid to the reactor, oscillate and mix well, and react at room temperature for 60 minutes, then remove the liquid under negative pressure; add dichloromethane 4ml, shake and mix for 30 seconds, remove the washing liquid under negative pressure, and repeat the washing for 7 times; take a small amount of peptid...

Embodiment 2

[0022] : Solid phase synthesis of peptide-resin cleavage

[0023] Take the peptide-resin obtained in Example 1, add 2 ml of lysis solution (95% trifluoroacetic acid, 2.5% water, 2.5% triisopropylsilane), stir and react at room temperature for two hours; then suck out the cutting solution and use A small amount of TFA was used to wash the resin in the reaction bottle, and the TFA was filtered out and incorporated into the cutting solution; the filtered cutting solution was sucked dry under negative pressure, and precipitated with ice ether, separated and dissolved in 1ml of water.

Embodiment 3

[0024] : Purification of NB06

[0025] Take a small amount of dissolved cleavage product, carry out high-pressure liquid chromatography, determine the retention time of the product, and separate the product. The conditions for reverse-phase high-pressure liquid phase purification are: C8 column (3.9 × 150mm, waters company), mobile phase A: 0.1% TFA / H 2 O, B: 0.1% TFA / acetonitrile, gradient elution, flow rate 1ml / mm, monitoring the absorption peak at 214nm. The result is shown in Figure 1: there are two main elution peaks, respectively the elution peak (recorded as P1) of 17.422 minutes and the elution peak (recorded as P2) of 17.712 minutes; Wherein P1 is the target compound, and its peak area is about 40% of the total area. The eluted peak of P1 was collected and vacuum freeze-dried to obtain purified NB06.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com