Industrial process for production of high-purity diaryl carbonate

A kind of technology of diaryl carbonate and dialkyl carbonate, which is applied in the industrial preparation field of high-purity diaryl carbonate, and can solve the problems such as the existence of by-products with a middle boiling point and a method for removing them which are not disclosed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0246]

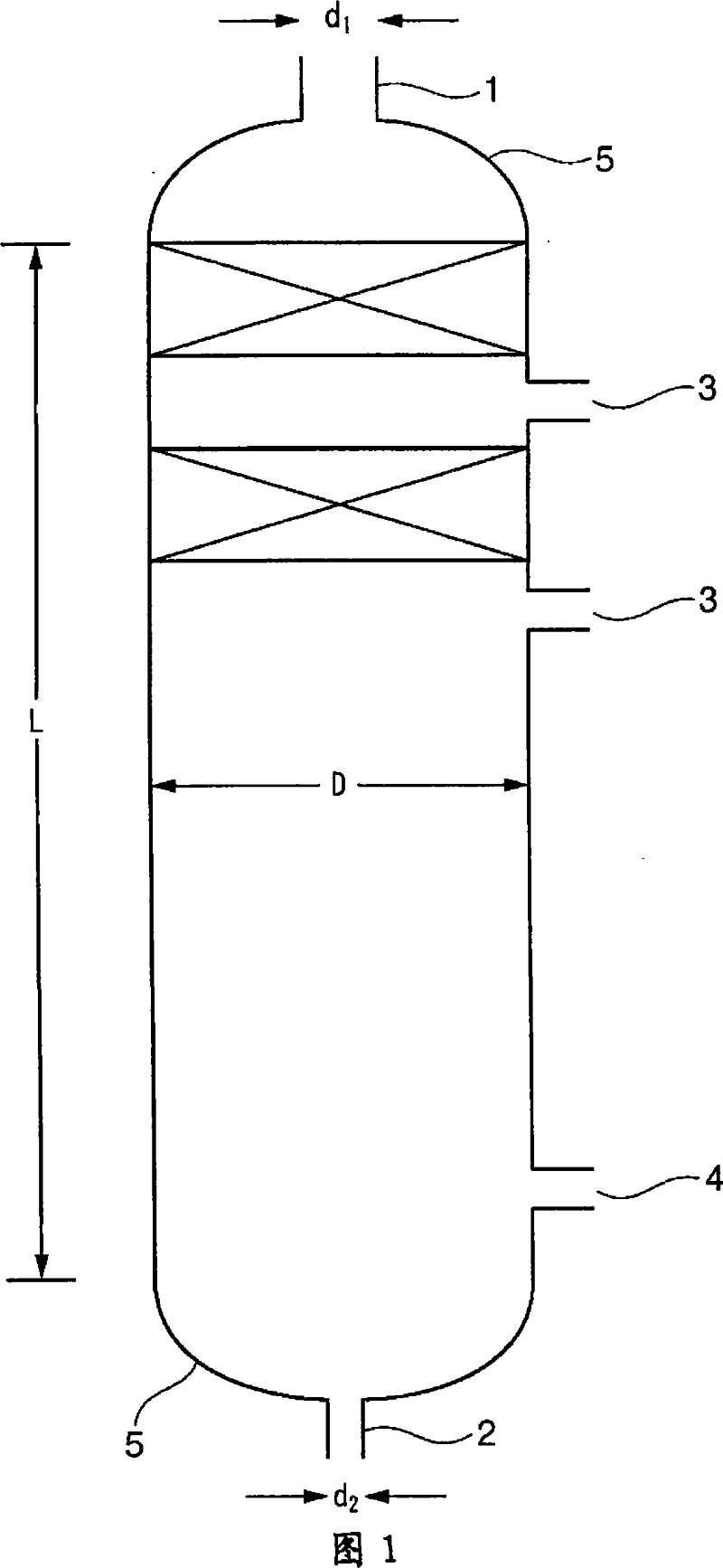

[0247] Using this L=3100cm, D=500cm, L / D=6.2, n=30, D / d shown in Figure 1 1 =3.85, D / d 2 =11.1 continuous multistage distillation column. In addition, in this embodiment, as internal parts, two Mellapak (metal orifice corrugated packing) (the total number of stages is 11) are arranged on the upper part, and the lower part uses 2 , The number of holes is about 250 / m 2 perforated trays.

[0248]

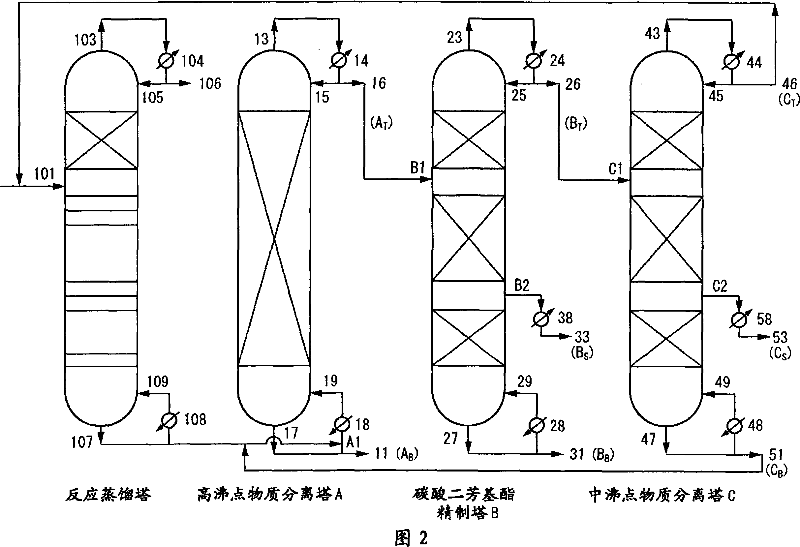

[0249] Using L as shown in Figure 2 A =1700cm, D A =340cm, and set n A As the separation column A, a continuous multistage distillation column with a Mellapak of =30 as internals was used.

[0250]

[0251] Using L as shown in Figure 2 B =2200cm, D B =280cm, and set n 1 =12, n 2 =18,n 3 =5 continuous multi-stage distillation columns with 3 Mellapaks as internals were used as the refining column B.

[0252]

[0253] Using L as shown in Figure 2 C =1500cm, D C =150cm, and set n 4 = 6, n 5 =10, n 6 3 Mellapaks of =7 are as the continuous multi-stage disti...

Embodiment 2

[0268] In addition to changing the distillation and separation conditions, the bottom temperature of the high boiling point material separation tower A is 210°C, the top pressure is 3800Pa, and the reflux ratio is 0.61, the bottom temperature of the diaryl carbonate refining tower B is 220°C, Top pressure is 6700Pa, reflux ratio is 1.5, and the tower bottom temperature of middle boiling point substance separation tower C is that 200 ℃, tower top pressure are 2400Pa, reflux ratio are except the condition of 0.35, carry out reactive distillation and by the method identical with embodiment 1 Separated by distillation. After 500 hours and 1000 hours, the purity of diphenyl carbonate was 99.999% by mass or higher, and the contents of the middle-boiling point by-products and high-boiling point by-products were all 1 ppm or less and could not be detected. In addition, in this diphenyl carbonate, no halogen was detected (1 ppb or less).

Embodiment 3

[0270] An aromatic polycarbonate was prepared by the method described in Example 1 of International Publication No. 99 / 64492 using the diphenyl carbonate obtained in Example 1. The obtained aromatic polycarbonate having a number average molecular weight of 10500 was injection-molded at 310° C. to produce a test piece (thickness: 3.2 mm). b of the test piece * The value (numerical value representing the degree of yellowness by the CIELAB method) was 3.2, which was completely free of yellow, colorless, and very excellent in transparency. After pulverizing these test pieces with a crusher, injection molding was repeated 5 times at 310°C, and b of the obtained test pieces * The value was 3.5, and no significant coloring was found. In addition, test pieces (b) produced by injection molding the aromatic polycarbonate were carried out * Value = 3.2) heat aging test (120 ° C, 500 hours), b * The value was 3.5, and no significant coloring was found.

[0271] In addition, b of an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com