Method for preparing of cerium oxide powder for chemical mechanical polishing and method for preparing of chemical mechanical polishing slurry using the same

A cerium dioxide, slurry technology, applied in chemical instruments and methods, cerium oxide/cerium hydroxide, nanotechnology for materials and surface science, etc., can solve problems such as low polishing speed and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] (1) Preparation steps of cerium precursor

[0033] This step is used for the preparation of cerium precursor.

[0034] The cerium precursor is not particularly limited, but is preferably selected from the group consisting of carbonates, hydroxide salts, chloride salts, oxalates and sulfates. Among them, it is more preferable to use CO containing 2 and H 2 Carbonate of O gas.

[0035] The raw material for the cerium precursor may be selected from the group comprising cerium nitrate, cerium acetate, cerium chloride and cerium sulfonate. It is preferable to use cerium nitrate or cerium acetate which can be used as a carbonate raw material.

[0036] Also, in the preparation of the cerium precursor, a precipitant for the preparation of a typical cerium precursor may be employed, and more specifically an ammonia compound, especially urea or ammonium carbonate is preferably used.

[0037] In the preparation of the above-mentioned cerium precursor, pores can be formed in t...

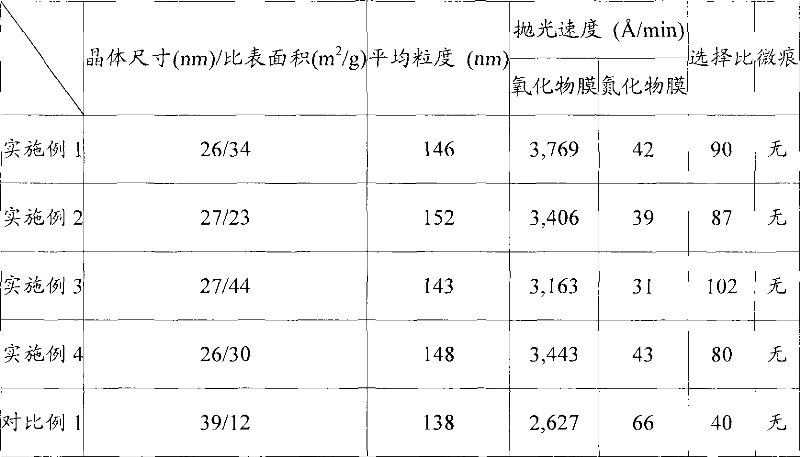

Embodiment 1

[0080] (Preparation of Ceria Powder)

[0081]0.5 mol of cerium nitrate was dissolved in 100 mL of distilled water, and itaconic acid as a pore-forming material was added in an amount of 0.3 wt % of cerium nitrate and stirred until it was completely dissolved. Then, 1.5 mol of urea as a precipitating agent was dissolved in 100 mL of distilled water, followed by mixing the two prepared solutions in a 500 mL precipitation reactor. While stirring at a speed of 200 rpm using a stirrer, a precipitation reaction was performed at 96° C. for 20 hours. The resulting powder was centrifuged and washed, then dried in an oven at 100 °C for 24 hours. Then, the powder was analyzed by XRD, and the result confirmed that it was orthorhombic cerium carbonate.

[0082] 1.5 kg of cerium carbonate powder was placed in an alumina crucible, and decomposed materials were removed by performing heat treatment at 350° C. for 24 hours under an oxygen atmosphere. 1.2 kg of oxide are obtained.

[0083] T...

Embodiment 2

[0091] (Preparation of Ceria Powder)

[0092] In addition to the use of ammonium sulfate ((NH 4 ) 2 SO 4 ) as a pore-forming material, ceria powder was prepared in the same manner as described in Example 1, and a crystal size of 26nm, 23m 2 Ceria powder with a specific surface area per g, a pore distribution of 3-10 nm pores distributed at a ratio of 42% of the total pores, and an average particle diameter of 65-473 nm.

[0093] (Preparation of Ceria Powder Dispersion Solution)

[0094] A ceria powder dispersion solution was obtained in the same manner as described in Example 1.

[0095] (Preparation of CMP slurry)

[0096] A CMP slurry was prepared in the same manner as described in Example 1 except for adjusting the average particle size to 152 nm.

[0097] The amount of abrasion of the prepared CMP slurry was measured, and as a result, the polishing rate of the oxide film was 3,406 Å / min and the polishing rate of the nitride film was 39 Å / min. Also, after observation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com