LED based on tuned distribution bragg reflector

A Bragg reflector and light-emitting layer technology, applied in lasers, phonon exciters, laser parts, etc., can solve the problems of limited application, reduced reflectivity, low DBR all-round reflectivity, etc., and achieves simple process and full-angle reflection. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

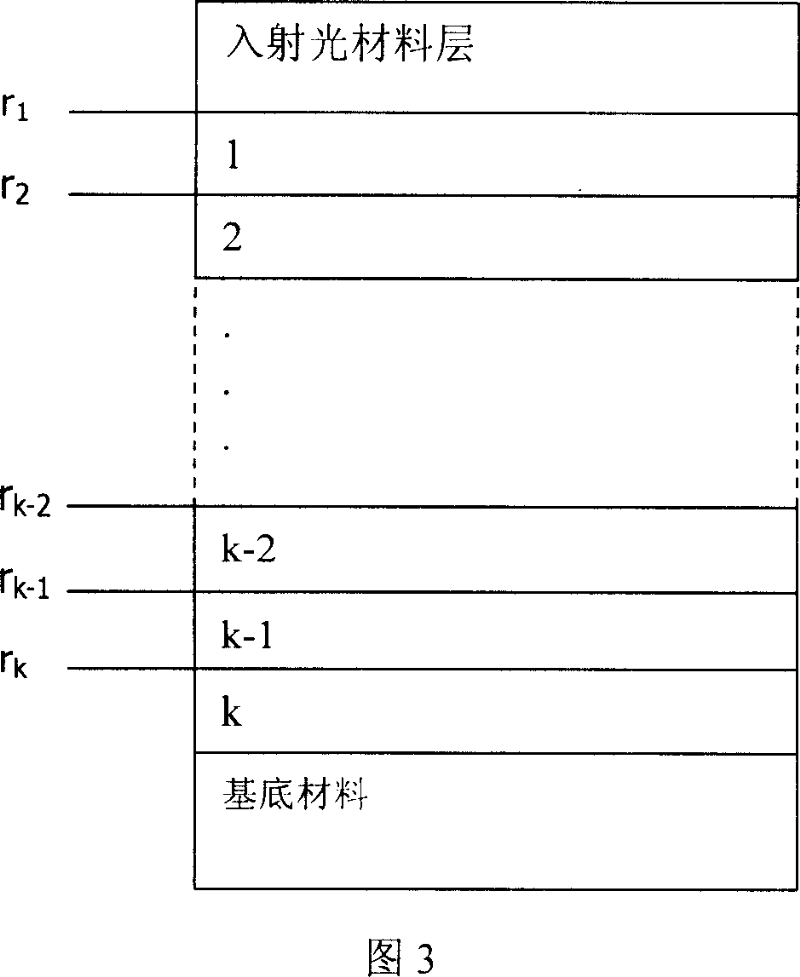

[0029] 1. Establish a calculation model for the reflectivity of the multilayer material thin film structure. For a multi-layer material thin film structure with given parameters (as shown in Figure 3), its reflection coefficient for incident light of a specific wavelength incident in a specific direction is obtained by iterative calculation of the following two formulas.

[0030]

[0031] δ k-1 =4πn k-1 h k-1 cosθ k-1 / λ (2)

[0032] Among them, r k and r k+1 are the reflection coefficients of the interfaces of the kth layer and the k+1th layer, respectively, h k with Respectively, the thickness of the medium of the kth layer and the equivalent refractive index of the interface of the kth layer (all reflective layers below the interface of the kth layer are equivalent to one layer) refractive index, θ k-1 and δ k-1 are the phase change of the light wave in the k-1 layer medium and the angle between its propagation direction and the vertical direction, and λ is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com