Method for preparing puddling iron concentrate by high-alumina iron ore

A technology of iron ore and iron concentrate, which is applied in the field of iron ore dealumination, can solve the problems of inability to dealuminate, complex embedding relationship, difficult dissociation, etc., achieve short leaching time, reduce energy consumption, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

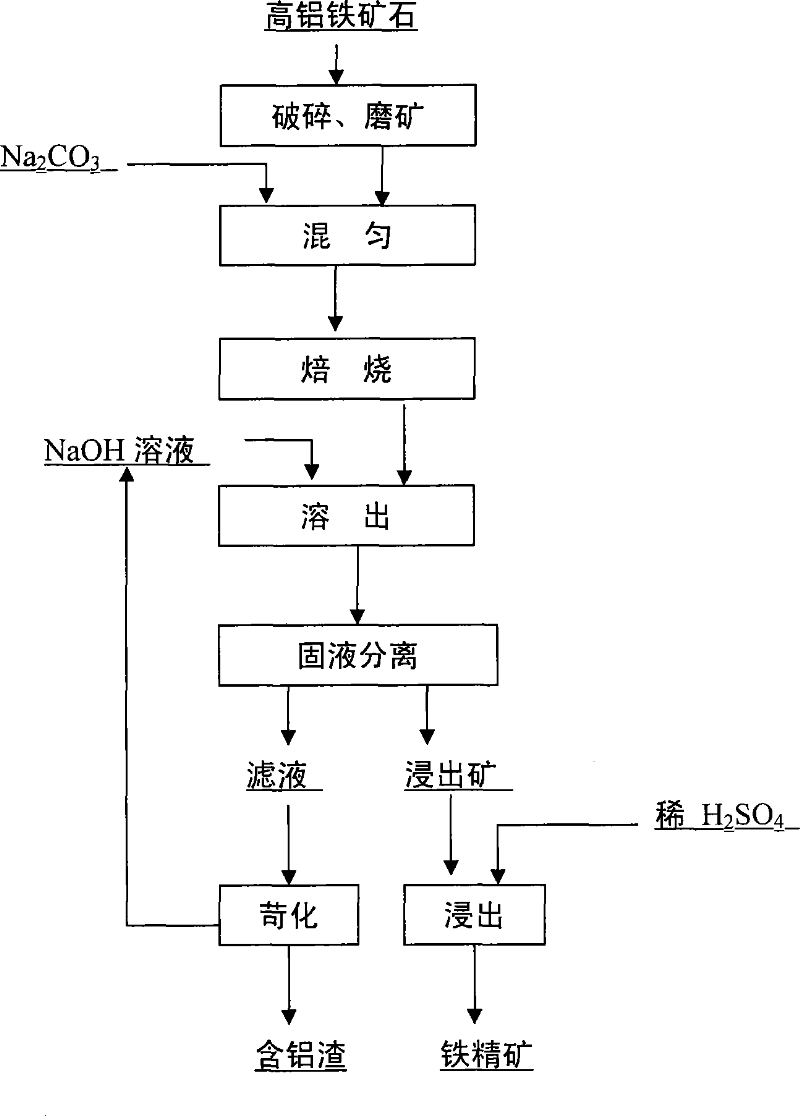

[0013] Embodiment 1, see accompanying drawing, TFe content 55.34%, Al 2 o 3 For the hematite ore with a content of 5.26%, after the ore is ground until the particle size is less than 0.074mm and accounts for about 40%, the Na 2 CO 3 Mix it with iron ore, roast it at 1050°C for 10min, put it in the reactor, and leaching it at 150°C according to the liquid-solid mass ratio L / S=4 / 1, NaOH concentration of 120g / L, and the leaching time is 5min, after solid-liquid separation, leaching with dilute sulfuric acid with a mass percentage concentration of 15% at 80°C, the leaching time is 10min, after solid-liquid separation, TFe content of 66.58%, Al 2 o 3 Content 1.94%, Na 2 Iron concentrate with 0.13% O content.

Embodiment 2

[0014] Example 2, see accompanying drawing, TFe content 47.94%, Al 2 o 3 The hematite ore with a content of 10.2% is crushed until the particle size is less than 0.074mm, accounting for about 50%, and the Na 2 CO 3 Mix it with iron ore, roast at 900°C for 30min, then put it in the reactor, leaching at 120°C with the liquid-solid mass ratio L / S=3 / 1, NaOH concentration of 150g / L, the leaching time is 15min, after solid-liquid separation, leaching with 1.0% dilute sulfuric acid at 100°C, the leaching time is 30min, after solid-liquid separation, TFe content of 60.43%, Al 2 o 3 Content 1.84%, Na 2 Iron concentrate with 0.2% O content.

Embodiment 3

[0015] Embodiment 3, see accompanying drawing, TFe content 46.34%, Al 2 o 3 The limonite ore with a content of 8.46% is crushed to a particle size of less than 0.074mm, accounting for about 60%, and the ratio of 25% by mass to Na 2 CO 3 Mix well, roast at 1000°C for 15min, then place in the reactor, leaching at 80°C with liquid-solid mass ratio L / S=6 / 1, NaOH concentration 80g / L, leaching time is 30min, solid-liquid After separation, it is leached with 3.5% dilute sulfuric acid at 120°C for 15 minutes. After solid-liquid separation, TFe content of 62.83%, Al 2 o 3 Content 1.93%, Na 2 Iron concentrate with 0.15% O content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com