Preparation method of size-controllable nano structural conductive polyaniline

A conductive polyaniline, nanostructure technology, applied in the field of nanomaterials, can solve the problem of difficult to obtain monodisperse or oriented micro/nanostructured products, poor controllability of polymer morphology and size, damage to polymer morphology and In order to overcome the problems of composition and other problems, it can overcome the poor controllability of product morphology and size, the method is simple, and the post-processing is exempted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

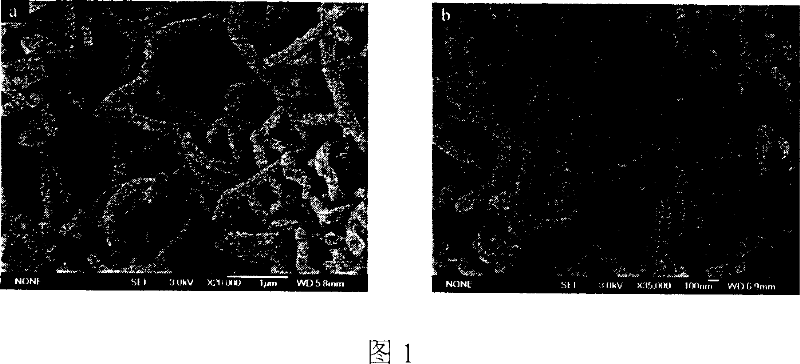

[0039] Embodiment 1, using ammonium persulfate (APS) as oxidant, under the condition of interfacial polymerization, prepare nanostructure conductive polyaniline

[0040] 1. Add 0.2ml of aniline (2.0mmol) to 10ml of chloroform solution, place in an ice bath (0-5°C) and stir magnetically until a uniform solution is formed;

[0041] 2. Dissolve 2.0 mmol of ammonium persulfate (E ox =2.0V) in 5ml of distilled water, and put it in the refrigerator for 30 minutes;

[0042]3. Carefully add 5ml of ammonium persulfate aqueous solution to the above-mentioned chloroform solution dissolved in aniline, and immediately form a clear water / organic phase interface;

[0043] 4. Put the above mixed solution under the condition of ice bath for 8 hours to stand and react, the product is formed at the interface and continuously enters the water phase;

[0044] 5. The product in the above water phase was extracted and washed three times with distilled water, absolute ethanol and ether in sequence,...

Embodiment 2

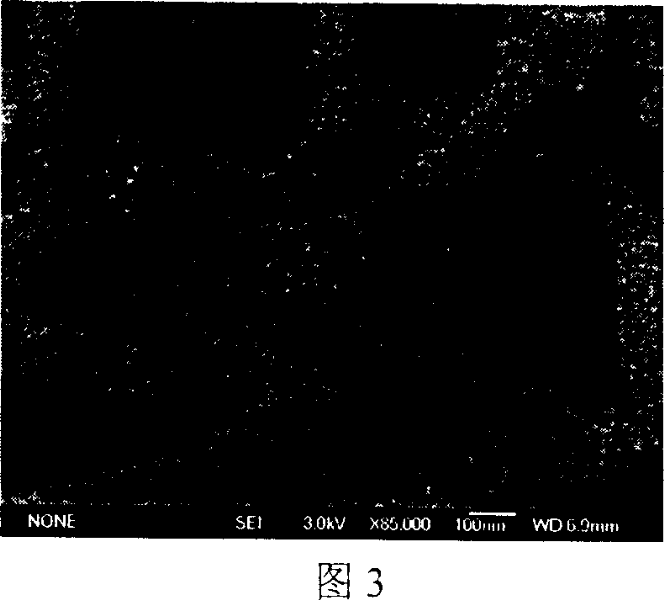

[0046] Embodiment 2, take ammonium persulfate (APS) as oxidant, prepare nano-conductive polyaniline under homogeneous polymerization condition

[0047] 1. Add 0.2ml of aniline (2.0mmol) to 15ml of distilled water, place in an ice bath (0-5°C) and stir magnetically until a uniform solution is formed;

[0048] 2. Add 2.0 mmol of ammonium persulfate (E ox =2.0V) was dissolved in 15ml of distilled water, and placed in the refrigerator for 30 minutes;

[0049] 3. Add the ammonium persulfate aqueous solution to the above-mentioned aniline-dissolved aqueous solution;

[0050] 4. The above mixed solution was allowed to stand and react for 12 hours in an ice bath (0-5°C);

[0051] 5. The product in the above water phase was extracted and washed three times with distilled water, absolute ethanol and ether in sequence, and finally vacuum-dried at room temperature for 24 hours to obtain dark green polyaniline powder.

[0052] The dark green product is determined by infrared and ultravi...

Embodiment 3

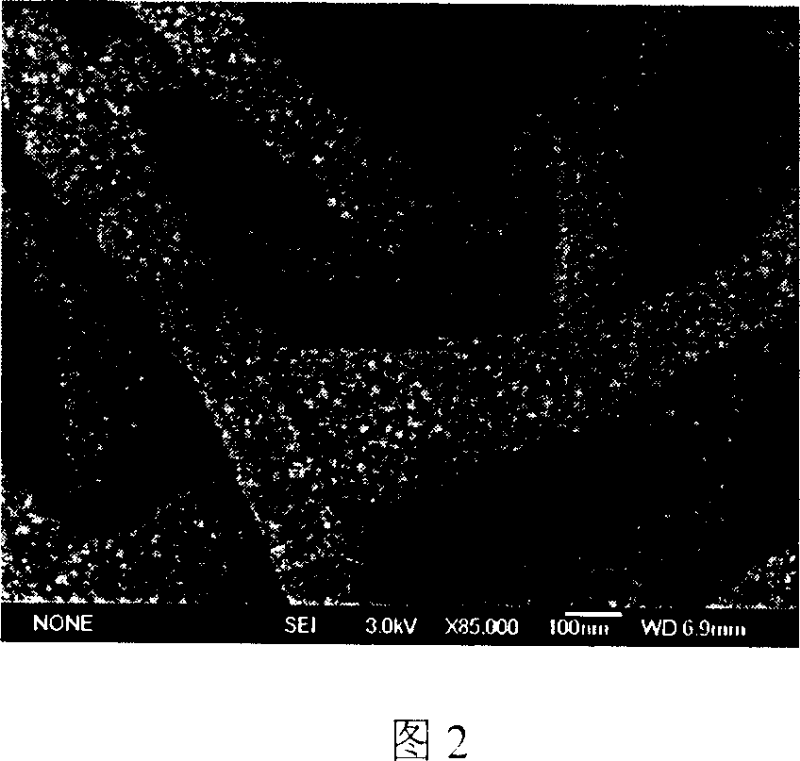

[0053] Embodiment 3, with Ce (SO 4 ) 2 Preparation of nano-conductive polyaniline under the condition of interfacial polymerization as oxidant

[0054] 1. Add 0.2ml of aniline (2.0mmol) to 10ml of chloroform solution, place in an ice bath (0-5°C) and stir magnetically until a uniform solution is formed;

[0055] 2. Add 4.0 mmol of Ce(SO 4 ) 2 (E ox =1.44V) was dissolved in 5ml of distilled water, and placed in the refrigerator for 30 minutes;

[0056] 3. Add 5ml Ce(SO 4 ) 2 The aqueous solution was carefully added to the above-mentioned chloroform solution in which aniline was dissolved, and a clear water / organic phase interface was formed immediately;

[0057] 4. Put the above mixed solution under the condition of ice bath for 8 hours to stand and react, the product is formed at the interface and continuously enters the water phase;

[0058] 5. The product in the above water phase was extracted and washed three times with distilled water, absolute ethanol and ether in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com