Process and equipment for manufacturing polymer enveloped control-released fertilizer

A technology of controlled-release fertilizers and polymers, applied in the form of fertilizers, urea compound fertilizers, fertilizer mixtures, etc., can solve problems such as limited application, limited development, technological methods and equipment inventions, and achieve strong controllability and operability of equipment The effect of wide range and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

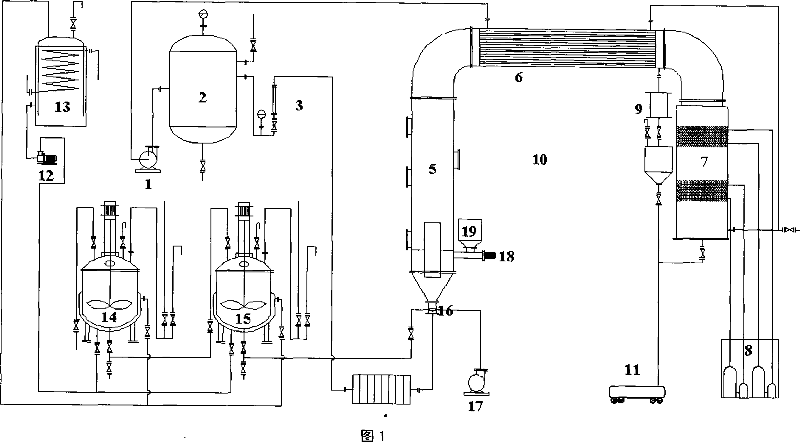

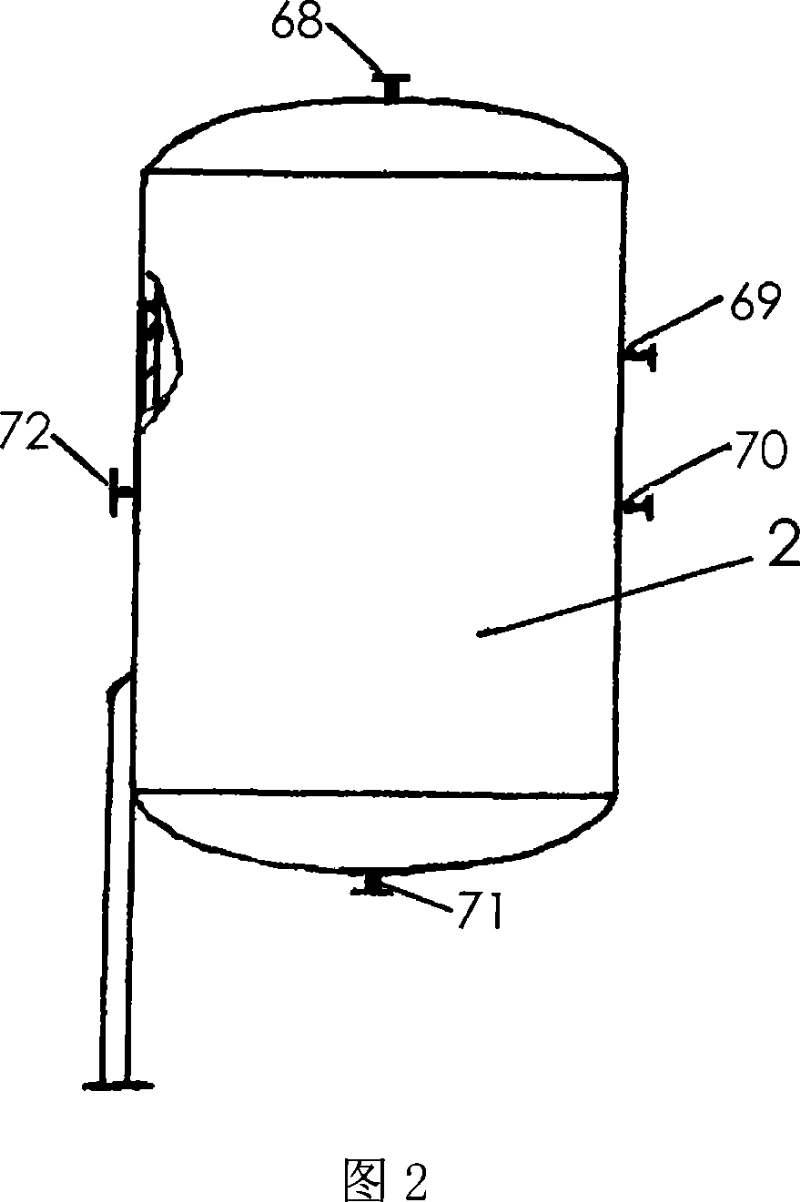

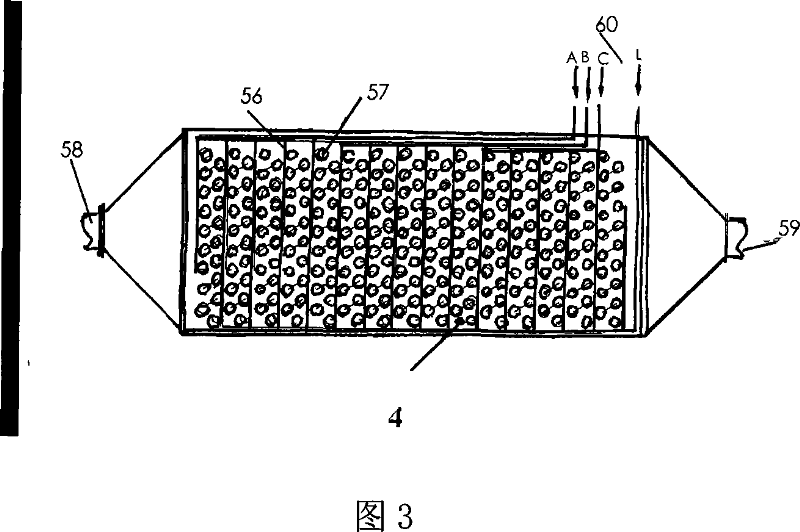

[0033] The invention provides a process and equipment for manufacturing polymer-coated controlled-release fertilizer. As shown in Figure 1, the spray precipitation phase inversion method coating process flow chart. The process combines the fluidized bed spray pyrolysis method with the solvent evaporation precipitation phase inversion method, and establishes a spray precipitation phase inversion method for preparing fertilizer controlled release membranes based on a spray fluidized bed. This method first makes the material particles in a stable circulating fluidized state, and then uses a two-fluid nozzle to spray organic polymers and other film-forming liquids on the surface of moving particles, and uses hot air to promote the deposition of film-forming liquids on the particle surfaces. The solvent and solute are phase separated, the solvent changes from a liquid phase to a gas phase and volatilizes, and the solute changes from a highly dispersed liquid phase to a solid phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com