Making technology for Al2O3/Cu electrical contact material

A technology of electrical contact material and preparation process, which is applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems of complex process, high process cost, and long preparation time, and achieve uniform distribution, simple and reliable process method, fine particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

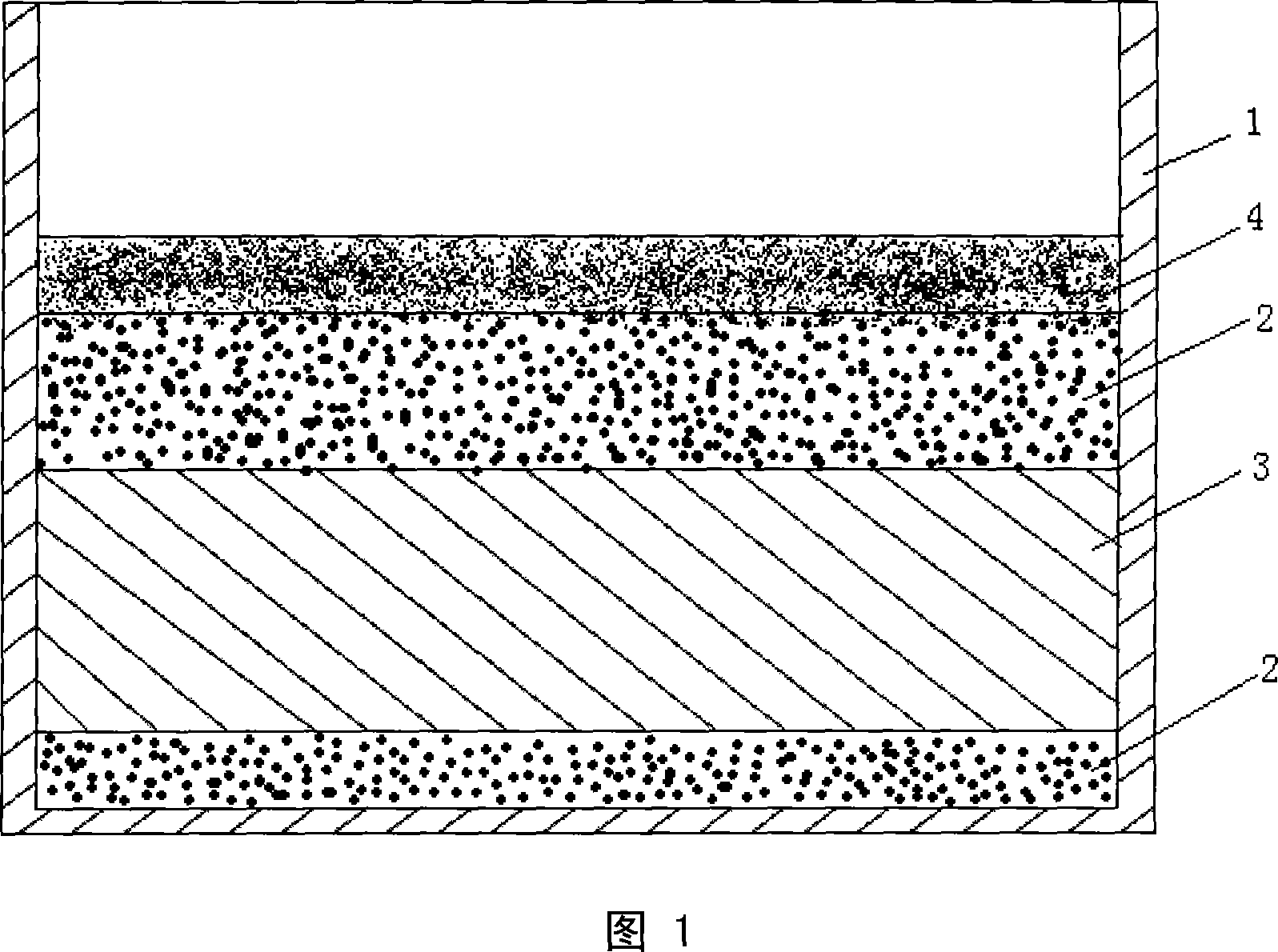

Image

Examples

Embodiment Construction

[0013] 1. Purchase Cu, Al metal powder and Cu with a particle size of 200 mesh 2 O powder

[0014] 2. Put Cu and Al metal powders into a ball mill for ball milling. The conditions that need to be met during ball milling are:

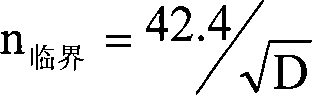

[0015] 1) The speed n≈0.82n of the ball mill is critical

[0016] no 临界 is the critical speed of the ball mill, in r / min.

[0017] Pick D is the inner diameter of the ball mill drum, in m.

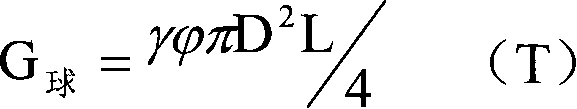

[0018] 2) The amount of balls loaded in the drum of the ball mill during ball milling is

[0019] G 球 =γπD 2 L / 4, the unit is T

[0020] In the formula, γ is the density of the steel ball, and the unit is T / m 3 , take γ=4.7T / m 3

[0021] is the filling coefficient of the ball mill:

[0022] For wet grid type ball mill=40%~45%

[0023] For dry grid type ball mill=25%~35%

[0024] For overflow ball mill=35%~40%

[0025] D is the inner diameter of the ball mill drum, in m

[0026] L is the length of the ball mill drum, in m.

[0027] 3) The amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com