Vertical type reeled paper glazing device and the printing system thereof

A light device and roll paper technology, applied in printing, printing machines, office printing equipment, etc., can solve the problems of increased production costs, large floor space, and large workshop area, so as to improve printing quality, reduce overall cost, Realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, through which the purpose and advantages of the present invention will become clearer.

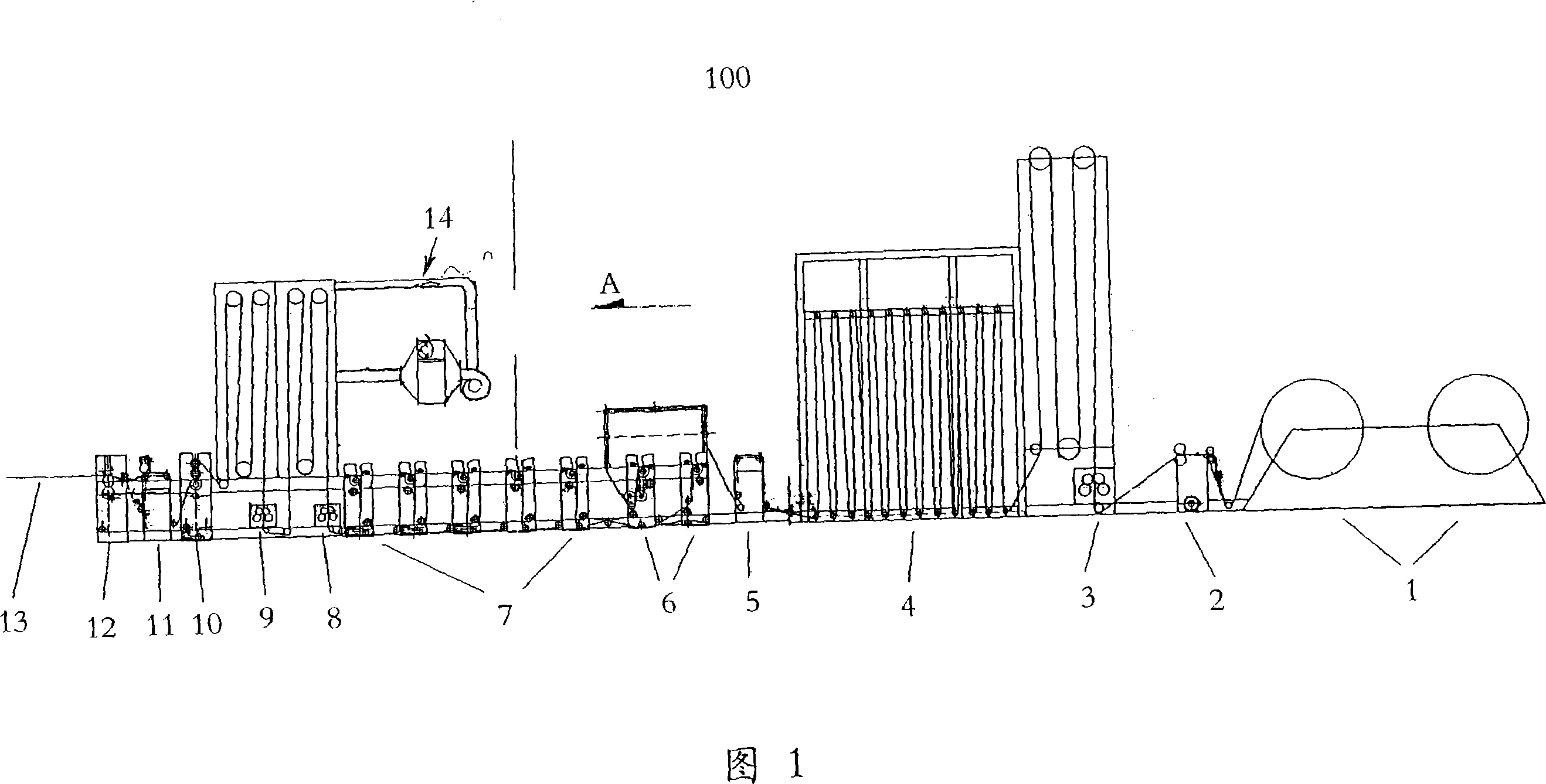

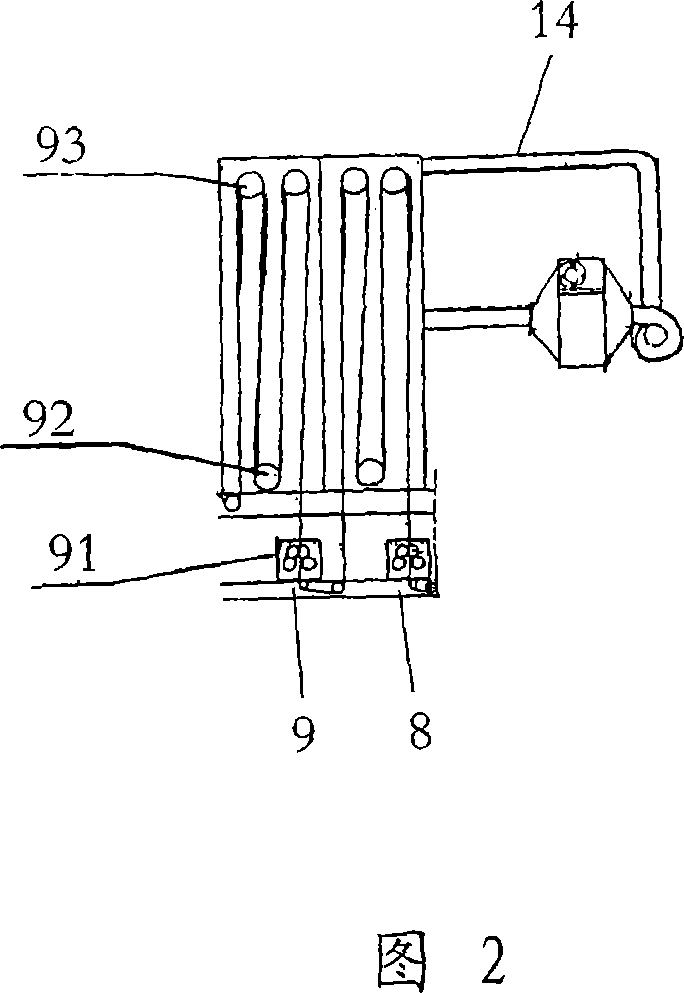

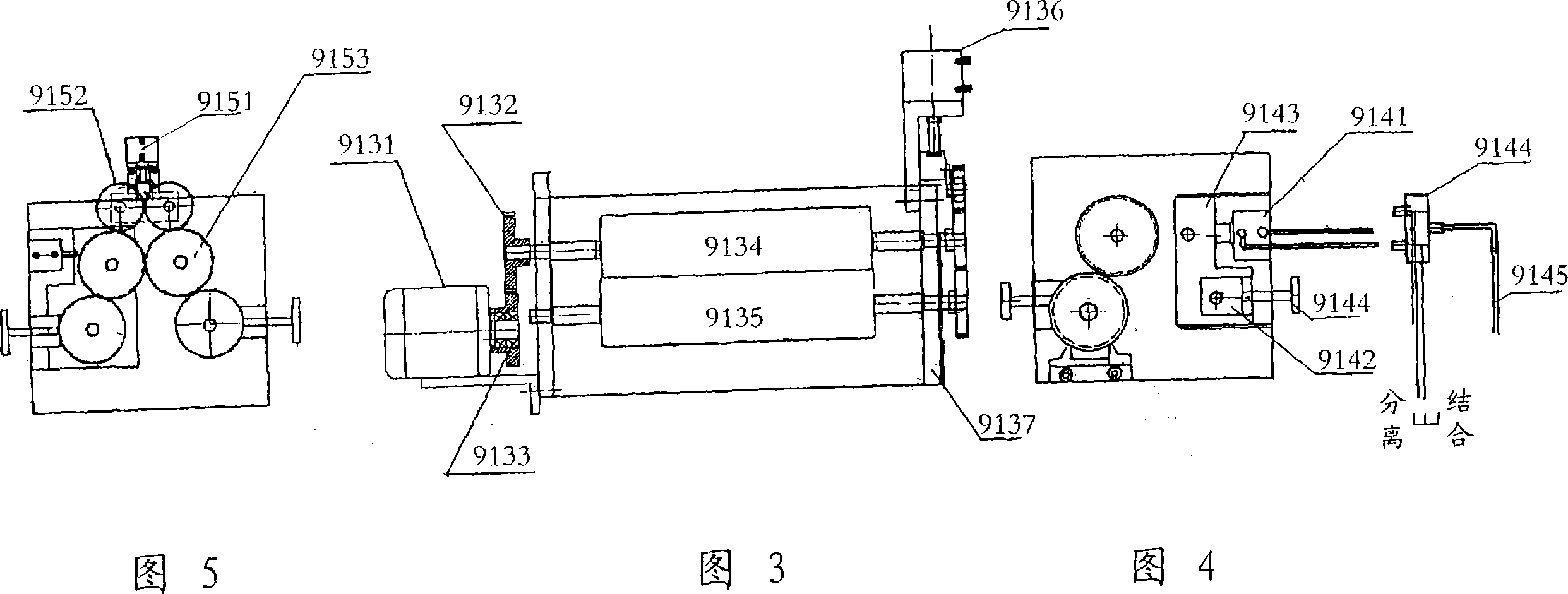

[0029] Fig. 1 is a schematic diagram of a printing system with a vertical roll paper glazing device of the present invention; Fig. 2 is a schematic diagram of a vertical roll paper coating slurry device and a glazing device with a drying part of the present invention; Fig. 3 -5 is a schematic diagram of the glazing head of the vertical web glazing device of the present invention.

[0030] Referring to Fig. 1 , the printing system 100 of the present invention includes a paper feeding roller 1, a roll paper receiving device 2, a primer coating device 3, a paper storage device 4, a deviation correction device 5, a reverse printing part 6, a front printing part 7, a coating Slurry device 8 , glazing device 9 , calendering device 10 , slitting device 11 , cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com