Woven or knit fabric containing crimped composite fiber having its air permeability enhanced by water wetting and relevant clothing

A composite fiber and water-wetting technology, applied in the direction of fabric, fiber type, fiber treatment, etc., can solve the problems of insufficient variation in air permeability, adhesion of woven fabrics, slow drying speed, etc., and achieve air permeability Improvement, air permeability reduction, heat retention improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

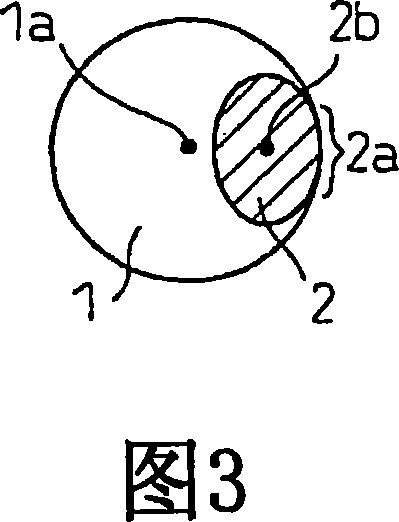

[0167] Modified polyethylene terephthalate obtained by copolymerizing nylon-6 with an intrinsic viscosity [η] of 1.3 and 2.6 mol% sodium isophthalate 5-sulfonate with an intrinsic viscosity [η] of 0.39, respectively Melting at 270° C. and 290° C., using the spinneret for side-by-side composite fibers described in JP-A-2000-144518 (spinning holes are 2 holes arranged substantially on the same circumference with a space (d) in between. The arc-shaped slits A and B are formed, the area SA of the arc-shaped slit A, and the slit width A 1 , the area SB of the arc-shaped slit B, and the slit width B 1 And the area SC surrounded by the inner peripheral surfaces of the arc-shaped slits A and B satisfies the following expressions ① to ④ at the same time as the spinning nozzle hole).

[0168] ①B 1 1

[0169] ②1.1≤SA / SB≤1.8

[0170] ③0.4≤(SA+SB) / SC≤10.0

[0171] ④d / A 1 ≤3.0

[0172] Extrude the above-mentioned polyethylene terephthalate from the side of the slit A at a discharge r...

Embodiment 2

[0178] Using the composite fiber used in Example 1 and common polyethylene terephthalate multifilament yarn (84dtex / 30fil), use the same double circular knitting machine of gauge number 28 as Example 1, it will Composite fiber strands and polyethylene terephthalate multifilament strands are alternately fed per strand, and knitted into a double rib weave with a weaving density of 54 courses / 2.54cm and 34 wales / 2.54cm Circular knit. The circular knitted fabric was subjected to dyeing processing, water absorption processing, and dry heat final setting in the same manner as in Example 1.

[0179] The weight per unit area of the knitted fabric obtained is 206g / m 2 , The stretch rate in the warp direction is 50%, the stretch rate in the weft direction is 110%, and the air permeability when dry is 150ml / cm 2 / s, air permeability when wet is 280ml / cm 2 / s, the change rate of air permeability is 87%, the air permeability is greatly improved when wet, and it is a knitted fabric tha...

Embodiment 3

[0185] A side-by-side composite fiber yarn similar to the composite fiber described in Example 1 was produced, and the composite fiber yarn was supplied to a common gauge 28 tricot warp knitting machine, and the above-mentioned composite fiber yarn was passed through with full draw-in. To the rear reed of the above-mentioned knitting machine, the common polyethylene terephthalate multifilament false-twisted crimping yarn (33dtex / 36fil) with a crimp rate of 20% is passed to the back of the above-mentioned knitting machine with a full draw-in. Front reed, woven into a warp-plain knitted fabric (back 10-12, front 23-10), woven into a warp-plain knitted fabric with an on-machine density of 80 courses / 2.54 cm.

[0186] The knitted fabric is dyed at a temperature of 130°C and maintained for 15 minutes to surface the latent crimp performance of the composite fiber, and then the dyed knitted fabric is treated with a fluororesin-based water-repellent processing liquid, and then heated a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com