Semiconductor structure and forming method thereof

A semiconductor and entity technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as coarse side effects of the upper cover layer, and achieve the effect of improving mechanical strength and increasing impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

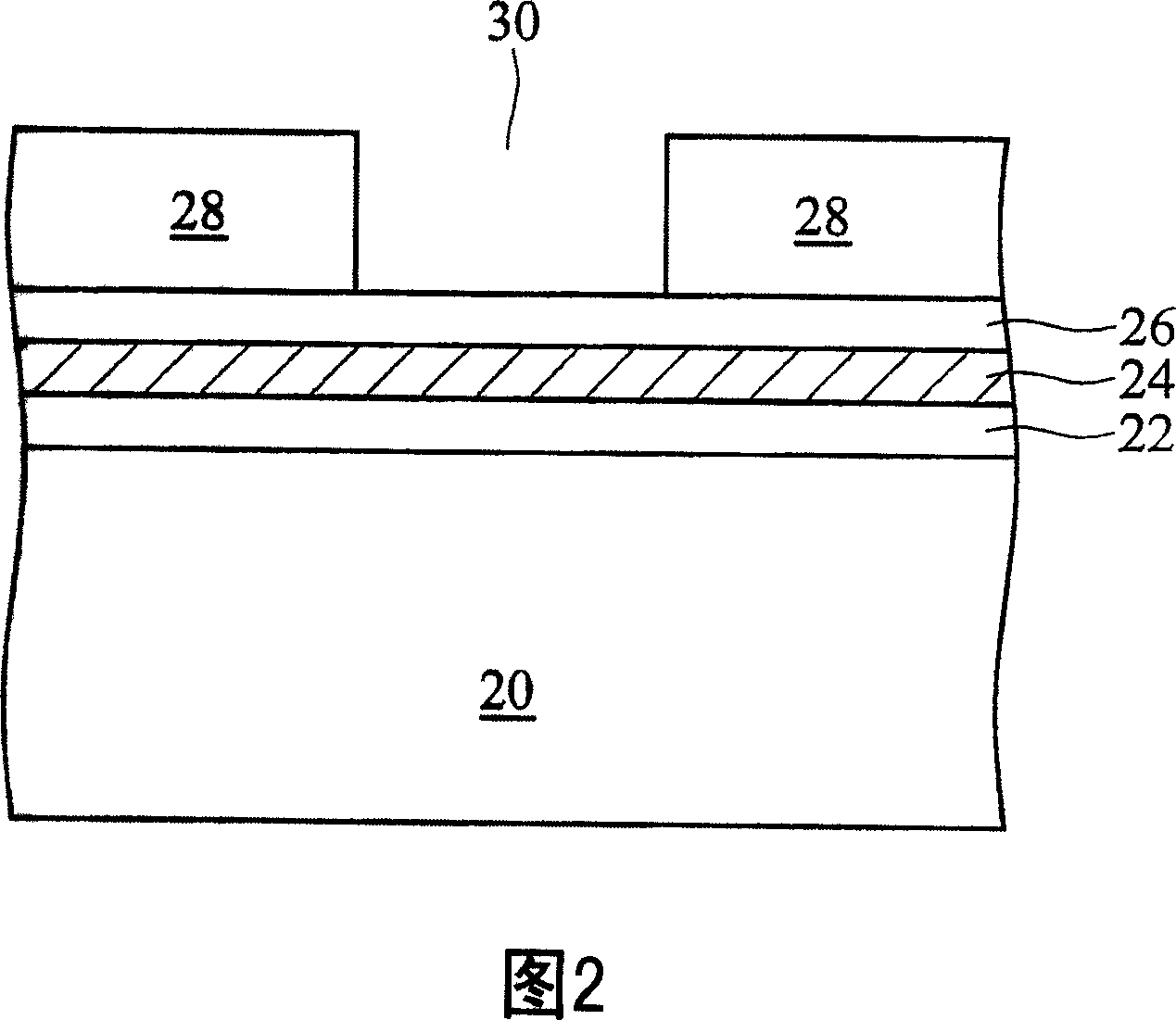

[0045] A preferred embodiment of the present invention is illustrated by FIGS. 1 to 9, wherein like reference numerals indicate similar elements.

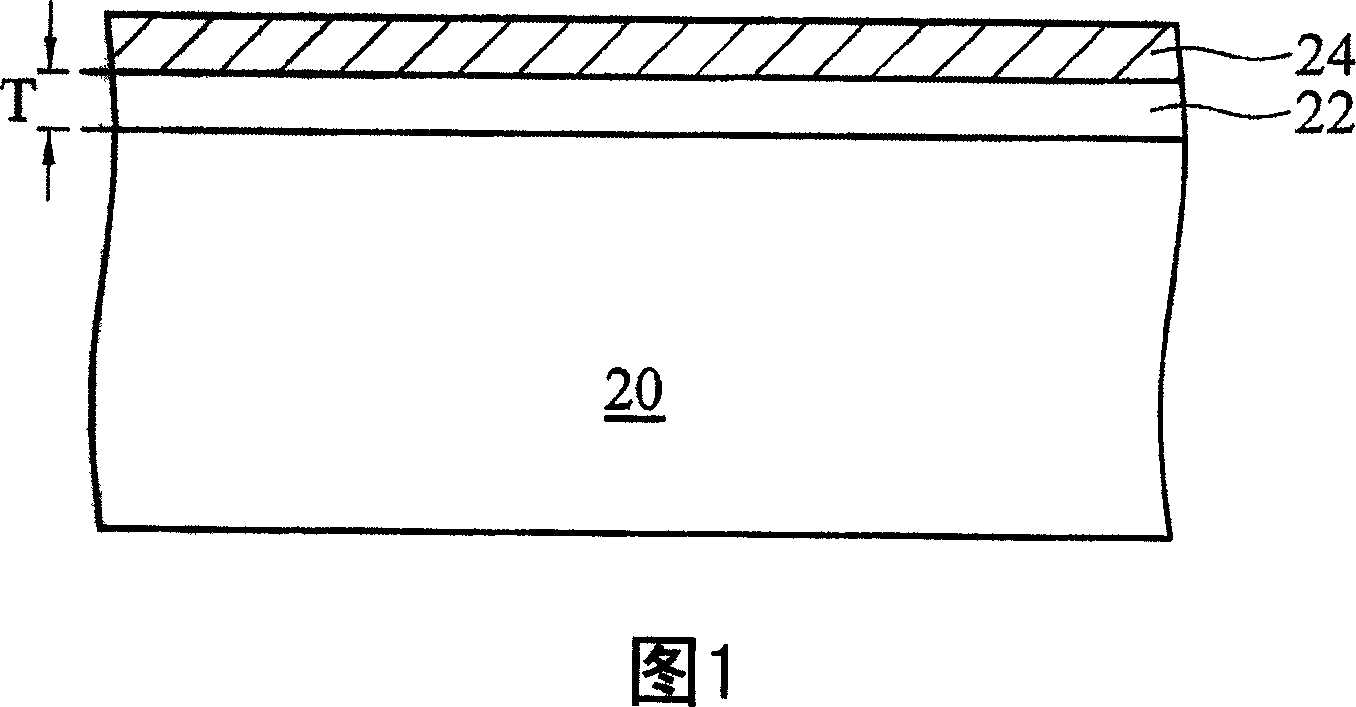

[0046] Please refer to FIG. 1 , which shows an upper cap layer 22 and a metal hard mask 24 formed on a low-k dielectric layer 20, which are used to insulate underlying components (not shown) and to be formed later. metal wires. The low-k dielectric layer 20 has a low k, preferably less than 3.5 and more preferably less than 2.5, and is therefore sometimes referred to as an extremely low-k dielectric material. The low-k dielectric layer 20 may include carbon-doped silicon oxide, fluorine-doped silicon oxide, organic low-k material, porous low-k material, and the like. The low-k dielectric layer 20 can be formed by, for example, spin coating, chemical vapor deposition, plasma enhanced chemical vapor deposition, low pressure chemical vapor deposition, and other known deposition techniques.

[0047] A capping layer 22 is then formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com