Semiconductor device and manufacturing method thereof

一种制造方法、半导体的技术,应用在半导体/固态器件制造、半导体器件、晶体管等方向,能够解决NPN晶体管难以得到高频特性及电流增幅率、扩散深度深、基极电阻值变高等问题,达到提高高频特性及电流增幅率、减小基极电阻值、减小集电极电阻值的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

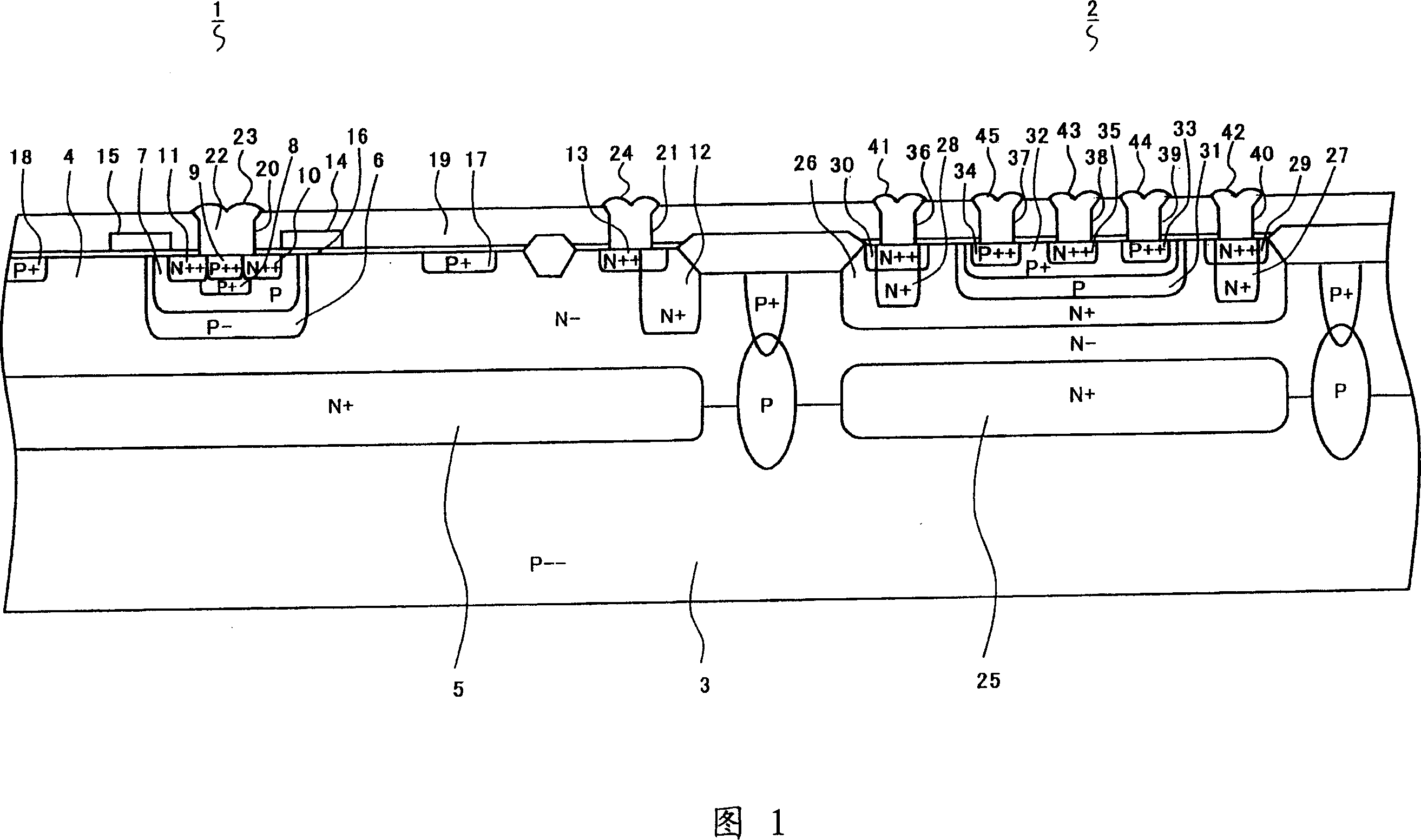

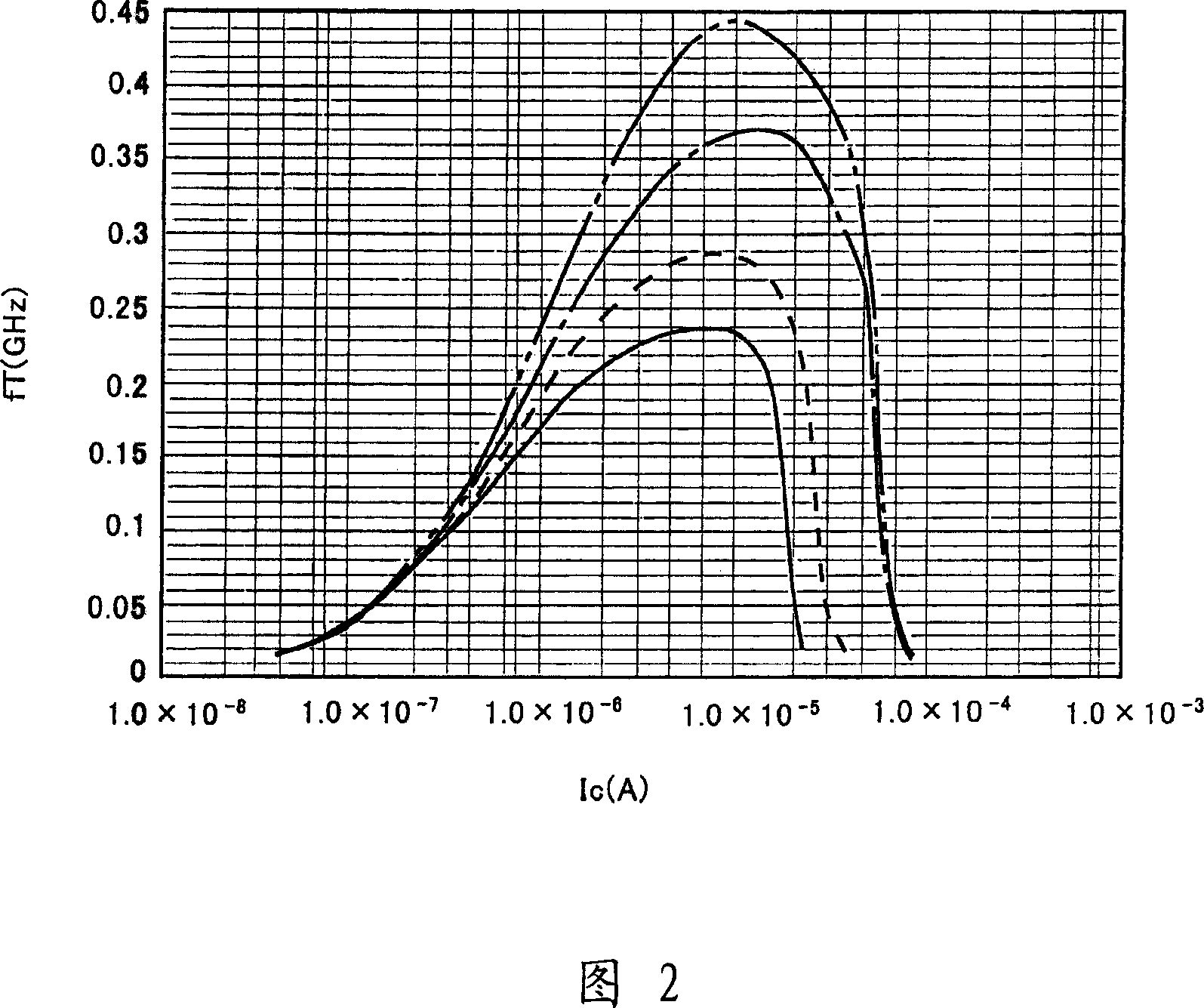

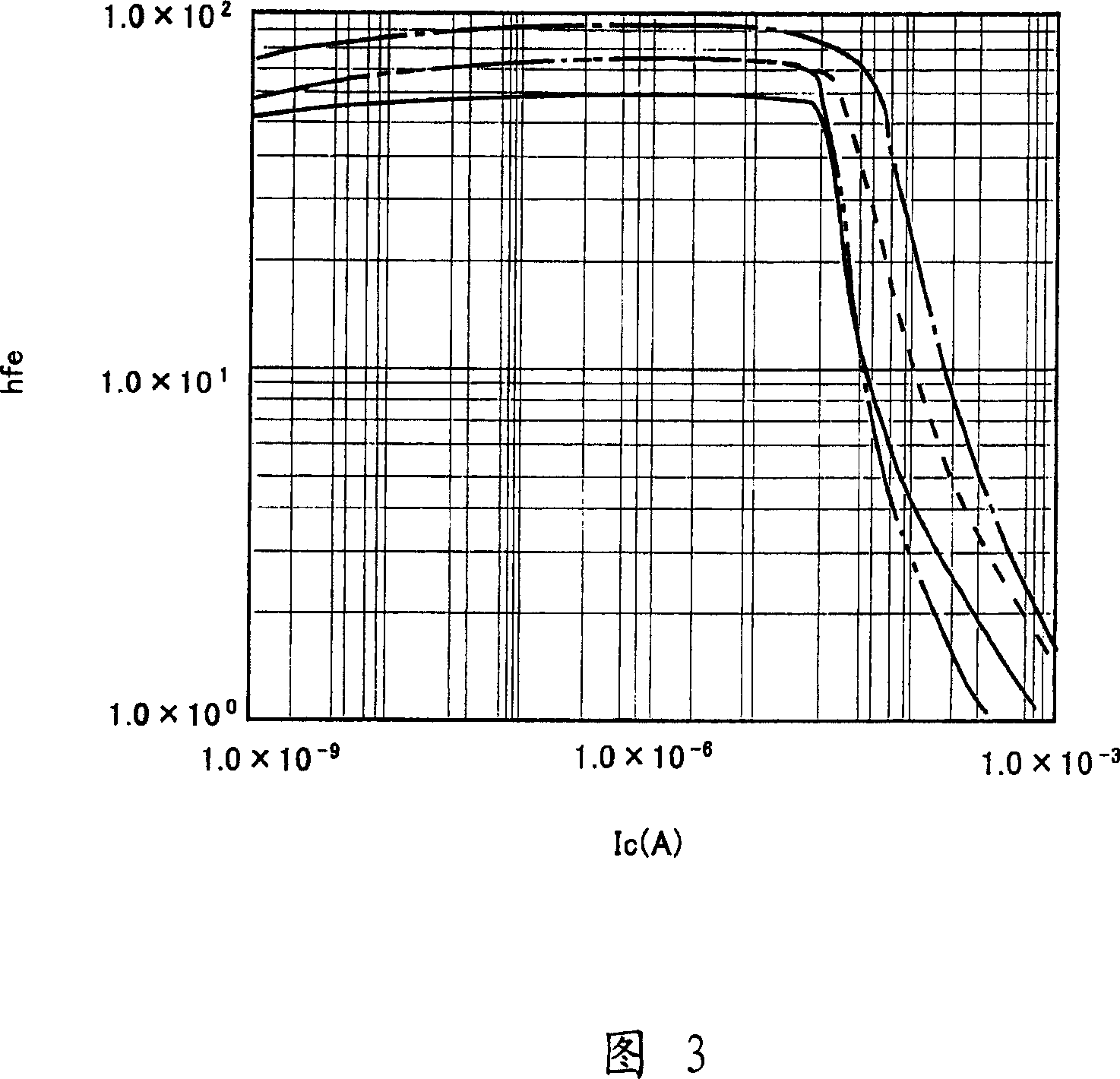

[0042] Hereinafter, a semiconductor device according to an embodiment of the present invention will be described in detail with reference to FIGS. 1 to 4 . FIG. 1 is a cross-sectional view illustrating a semiconductor device according to the present embodiment. FIG. 2 is a diagram illustrating the relationship between the cutoff frequency (fT) and the collector current (Ic) of the semiconductor device according to the present embodiment. FIG. 3 is a graph illustrating the relationship between the current amplification factor (hfe) and the collector current (Ic) of the semiconductor device according to the present embodiment. 4 is a diagram illustrating the relationship between collector-emitter current (Ice) and collector-emitter voltage (Vce) of the semiconductor device according to the present embodiment.

[0043] As shown in FIG. 1 , an N-channel MOS transistor 1 and an NPN transistor 2 are formed on the same P-type single crystal silicon substrate 3 . In addition, in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com