Electronic ballast

An electronic ballast and circuit technology, applied in the field of electronics, can solve the problems of poor circuit stability and reliability, insufficient output power, etc., and achieve the effects of good stability and reliability, prolonging service life, and improving power output capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

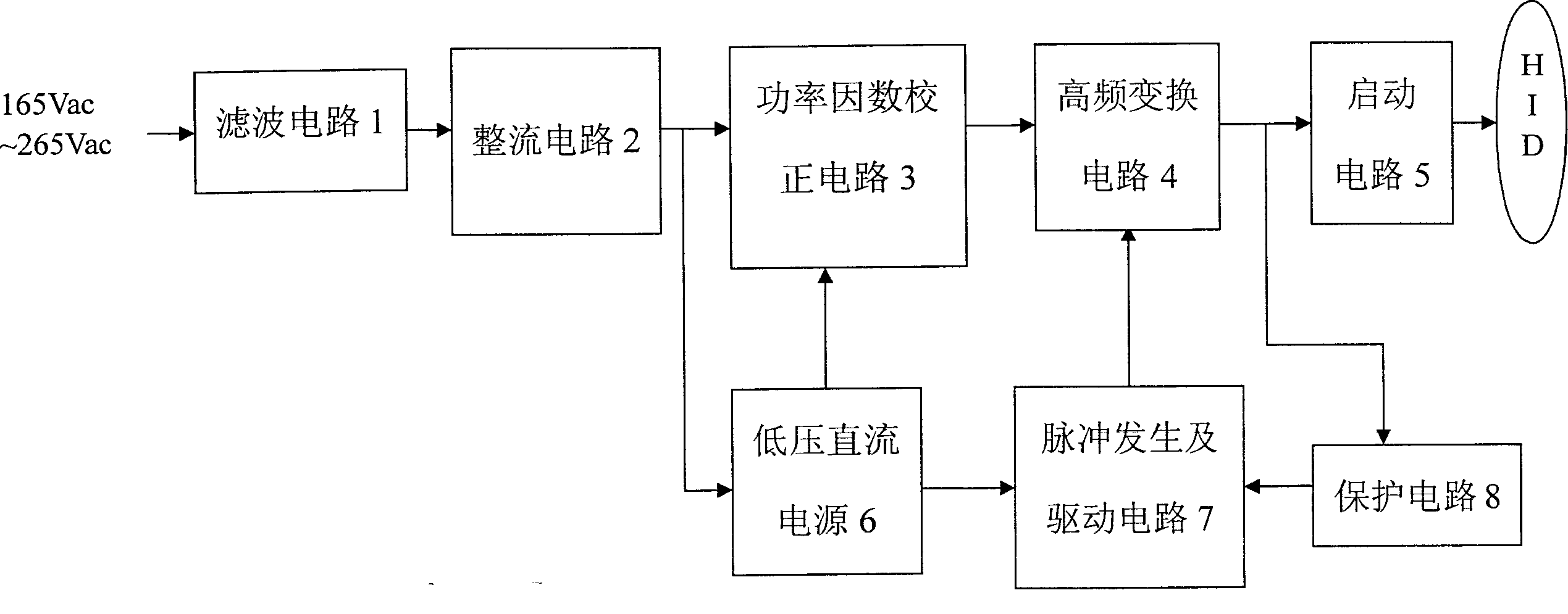

[0017] See figure 1 , the present invention includes a filter circuit 1, a bridge rectifier circuit 2, a power factor correction circuit 3, a high-frequency conversion circuit 4, and a starting circuit 5 connected in sequence, as well as a low-voltage DC power supply 6, a pulse generation and driving circuit 7, and a protection circuit 8. The input end of the low-voltage DC power supply 6 is connected to the output end of the bridge rectifier circuit 2, the output end of the low-voltage DC power supply 6 is connected to the power factor correction circuit 3 and the pulse generation and driving circuit 7, and the high-frequency conversion circuit 4 is connected to the pulse generation and driving circuit 7. A protection circuit 8 is connected between the circuits 7 .

[0018] See figure 2 , The filter circuit 1 is composed of a fuse FU1, a piezoresistor RV, capacitors C1, C2, C23-C25 and high-frequency inductors L1, L2.

[0019] The bridge rectifier circuit 2 is formed by co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com