Blast furnace cooling water backwater top pressure power generation

A residual pressure power generation and cooling water technology, which is applied in hydropower generation, cooling devices, renewable energy power generation, etc., can solve the problems of water loss and poor utilization of water conservancy resources, and achieve stable water head, stable flow, and low investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

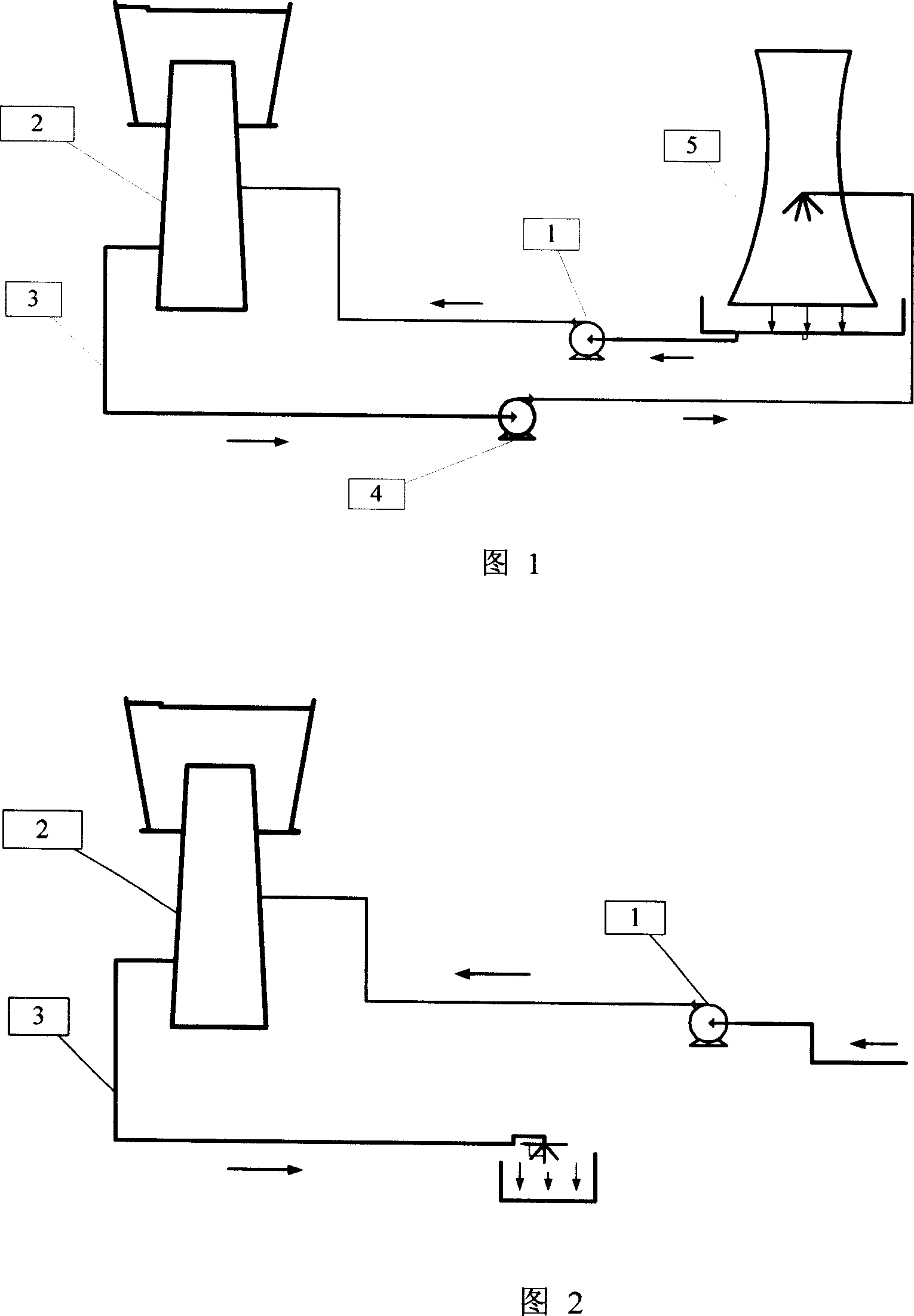

[0020] In Figure 1, the cooling water is pressurized by the water pump station (1) and sent to the blast furnace system (2) through the pipeline, and the return water flows automatically to the cooling water pump (4) through the return water pipeline (3), and is sent to the cooling water tower after being pressurized ( 5) cool down, then flow to the water pumping station (1) by itself, and use it in a closed cycle.

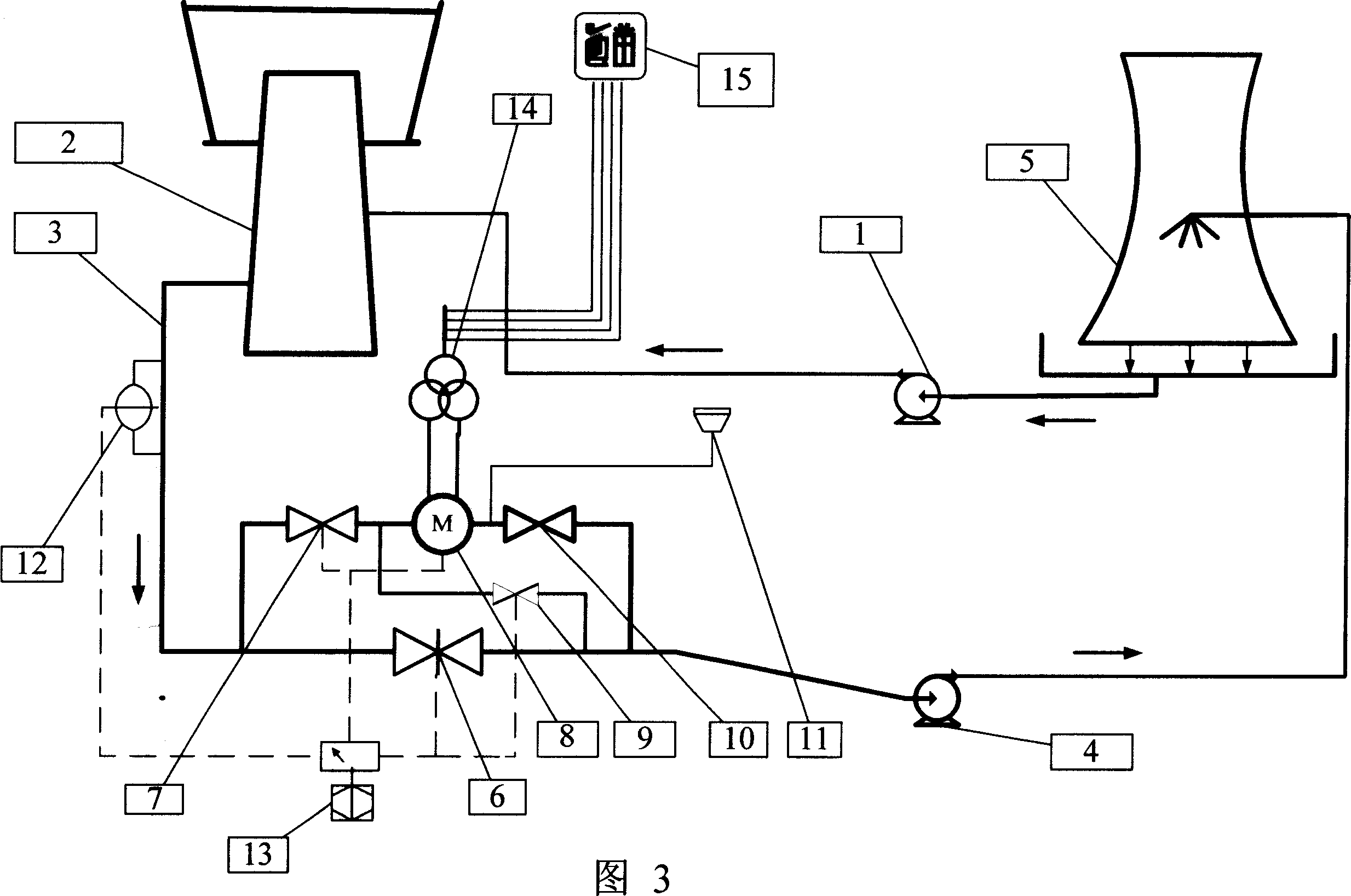

[0021] In Fig. 2, the cooling water is pressurized by the water pump station (1) and sent to the blast furnace system (2) through the pipeline, and the return water is freely discharged through the return water pipeline (3).

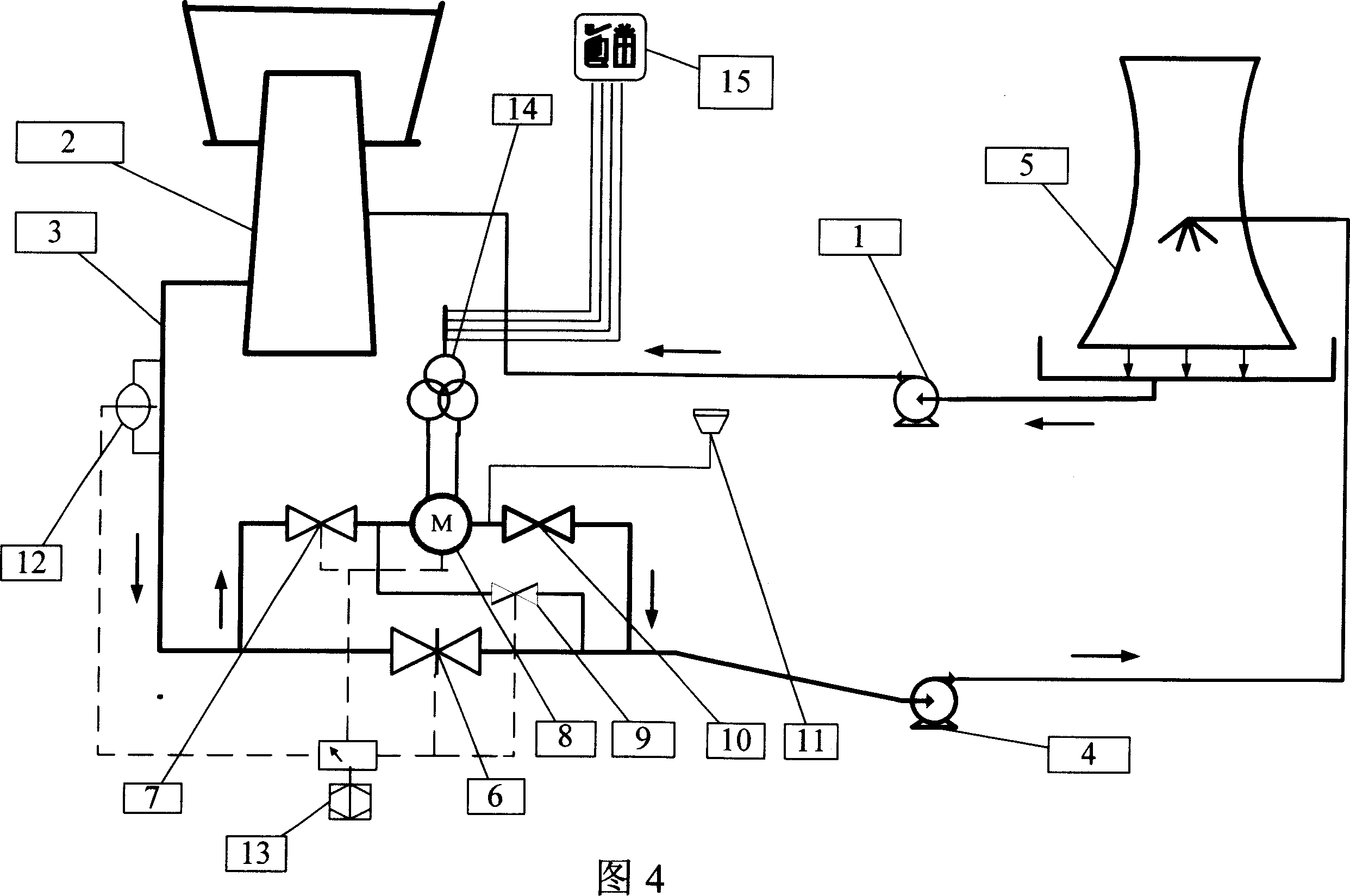

[0022] In Figure 3, the cooling water is pressurized by the water pump station (1) and sent to the blast furnace system (2) through the pipeline, and the cooling return water flows automatically to the bypass pipe hydro-generator system through the return water pipeline (3), and passes through the water inlet valve ( 7), water turbine genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com