Automatic feeder of machine tool

An automatic feeding and machine tool technology, which is applied to automatic/semi-automatic lathes, tool holder accessories, turning equipment, etc., can solve problems such as complex structure, poor stability, and complicated movements of the transmission system, and achieve a simple and automatic feeding process. Stable feeding process, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

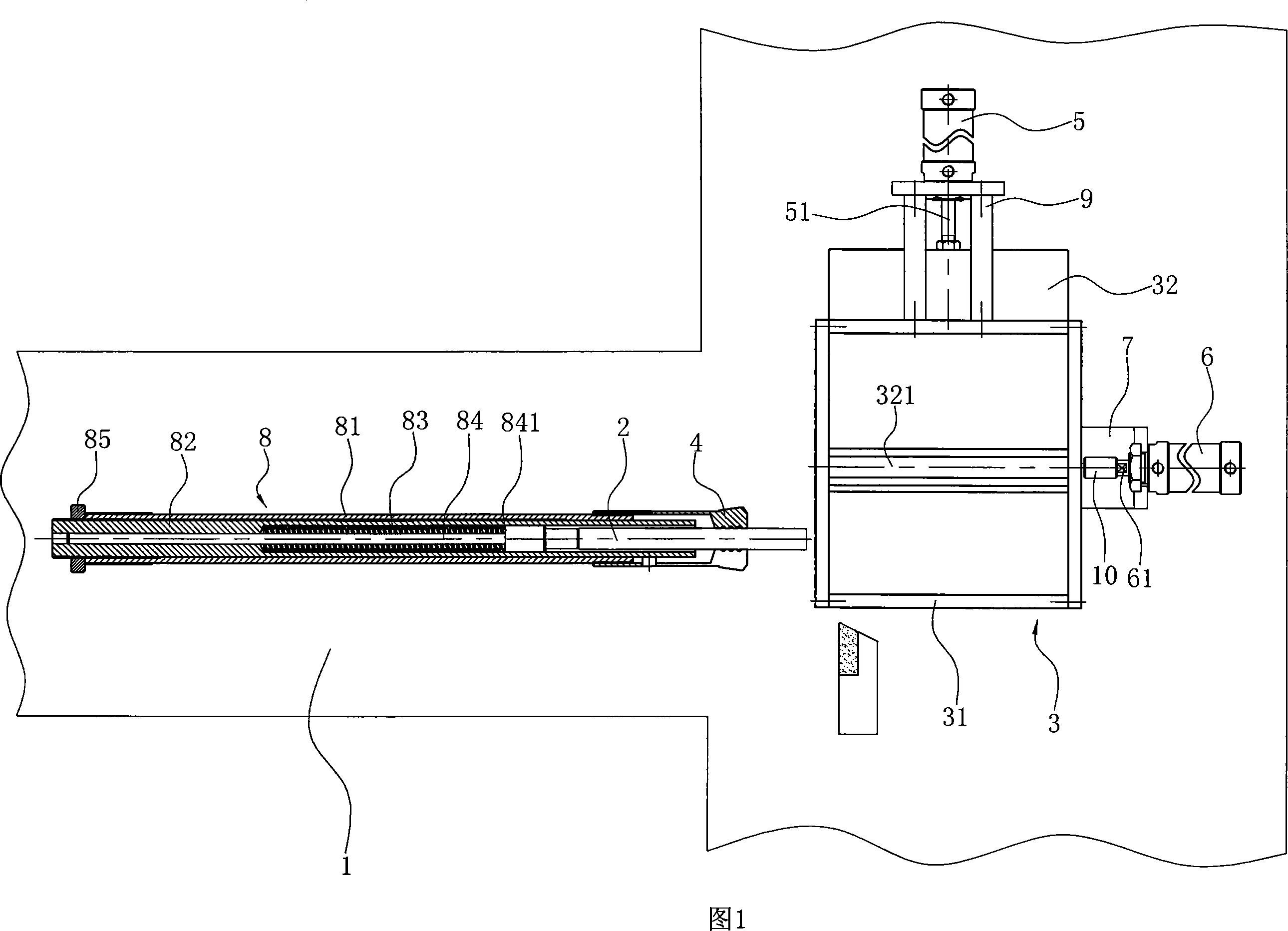

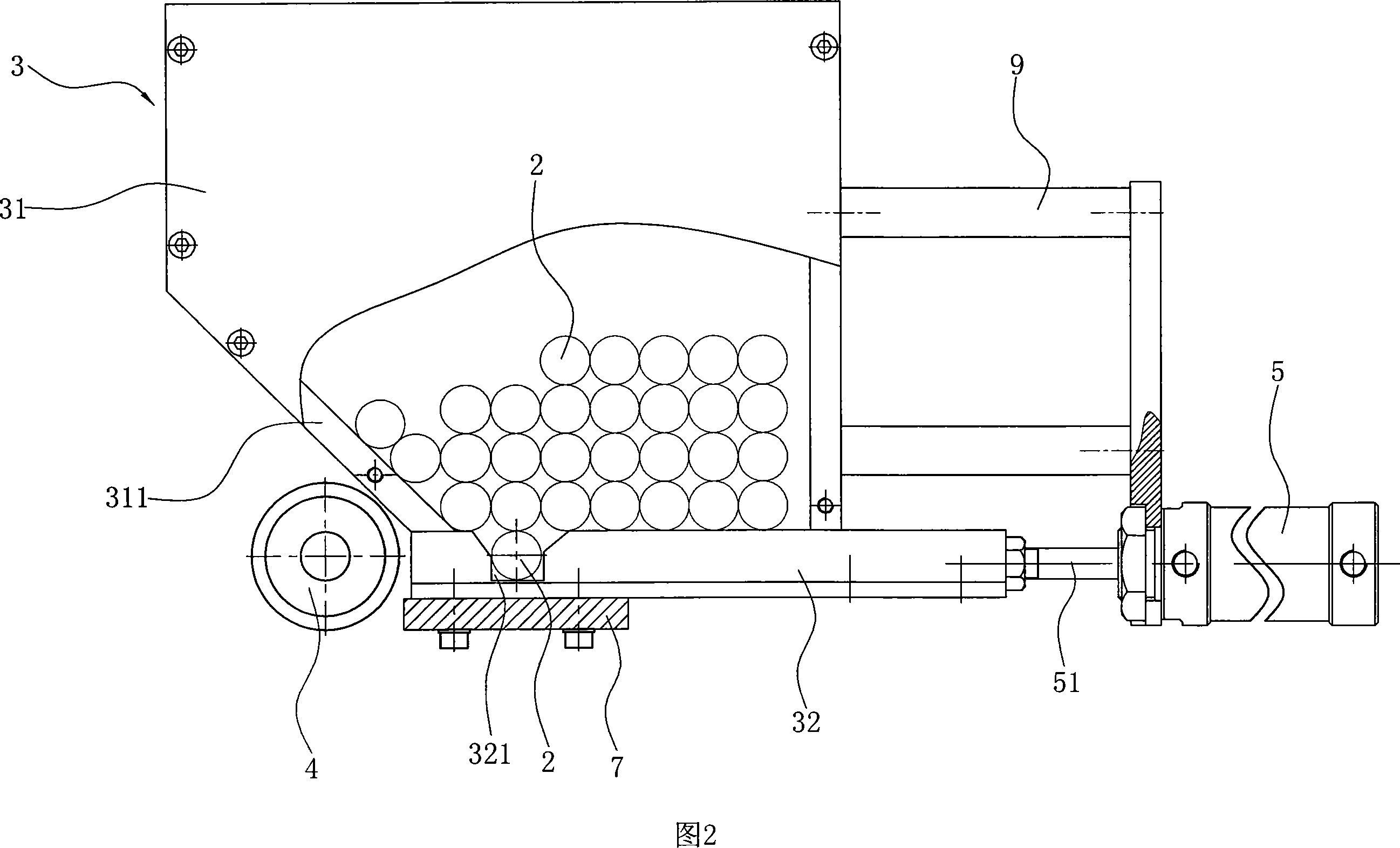

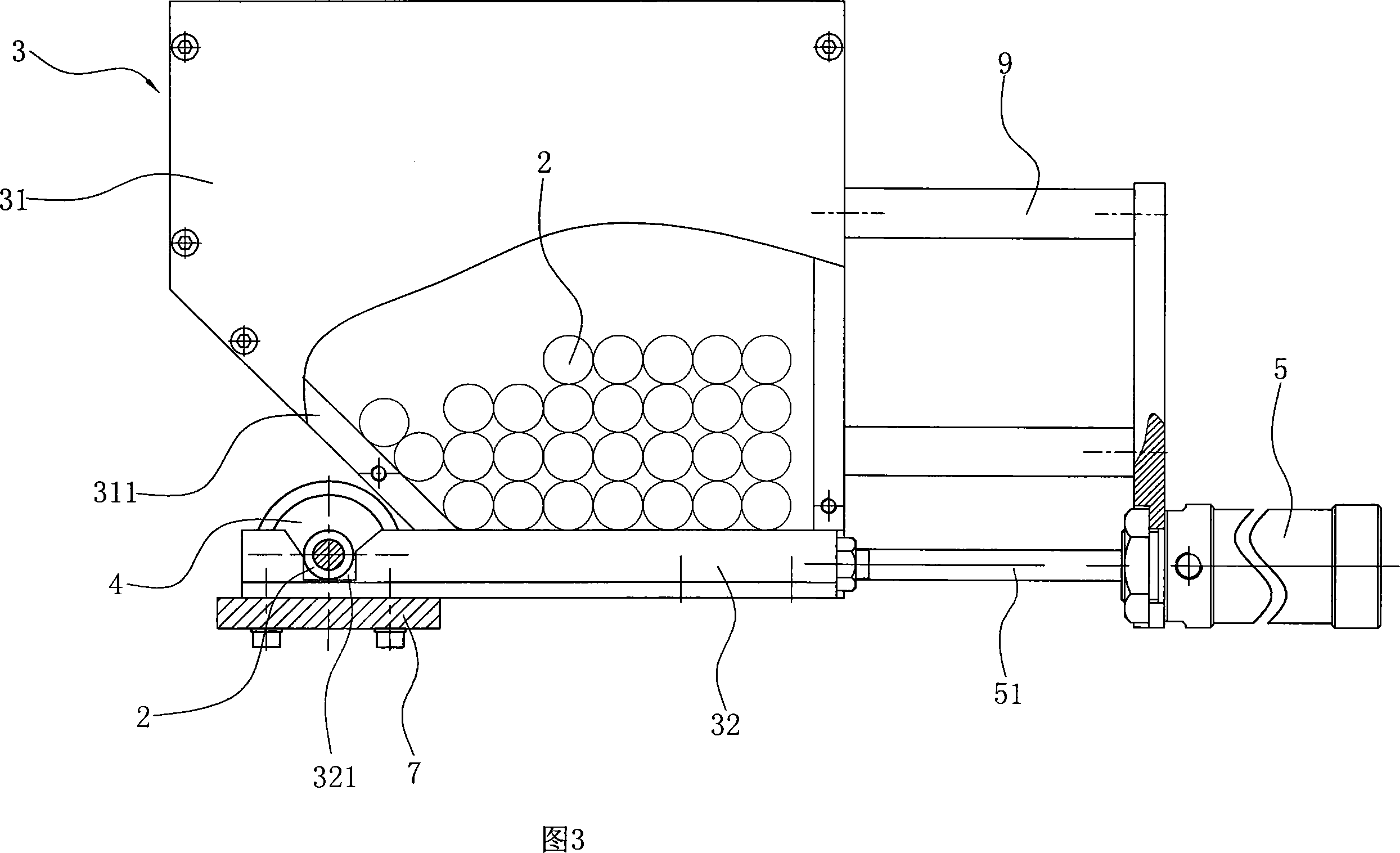

[0024] As shown in Figure 1, an automatic feeding device for a machine tool includes a storage bin 3 for storing workpieces 2, a radial feeding mechanism, an axial feeding mechanism, and a collet 4;

[0025] As shown in Figures 1 to 5, the storage bin 3: consists of a side frame 31 and a feed plate 32 arranged at the bottom of the side frame 31 to seal the bottom of the side frame 31, the radial width of the feed plate 32 is greater than that of the side frame. The radial width of the opening at the bottom of the frame 31, the side frame 31 is fixed on the frame 1 of the lathe by a support 9, the support 9 is made up of side walls and beams, the whole support 9 is fixed on the frame 1, and the support 9 is fixed on The structure on the frame 1 can adopt various conventional fixing methods, such as fixing methods such as screws or bolts. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com