A method for preparing the nano-electrode with the negative electronic erosion-resisting agent

A nano-electrode and resist technology, applied in the field of nano-electrode preparation, can solve the problems of optical lithography resolution difficult to reach nanoscale resolution, low efficiency, single electrode material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

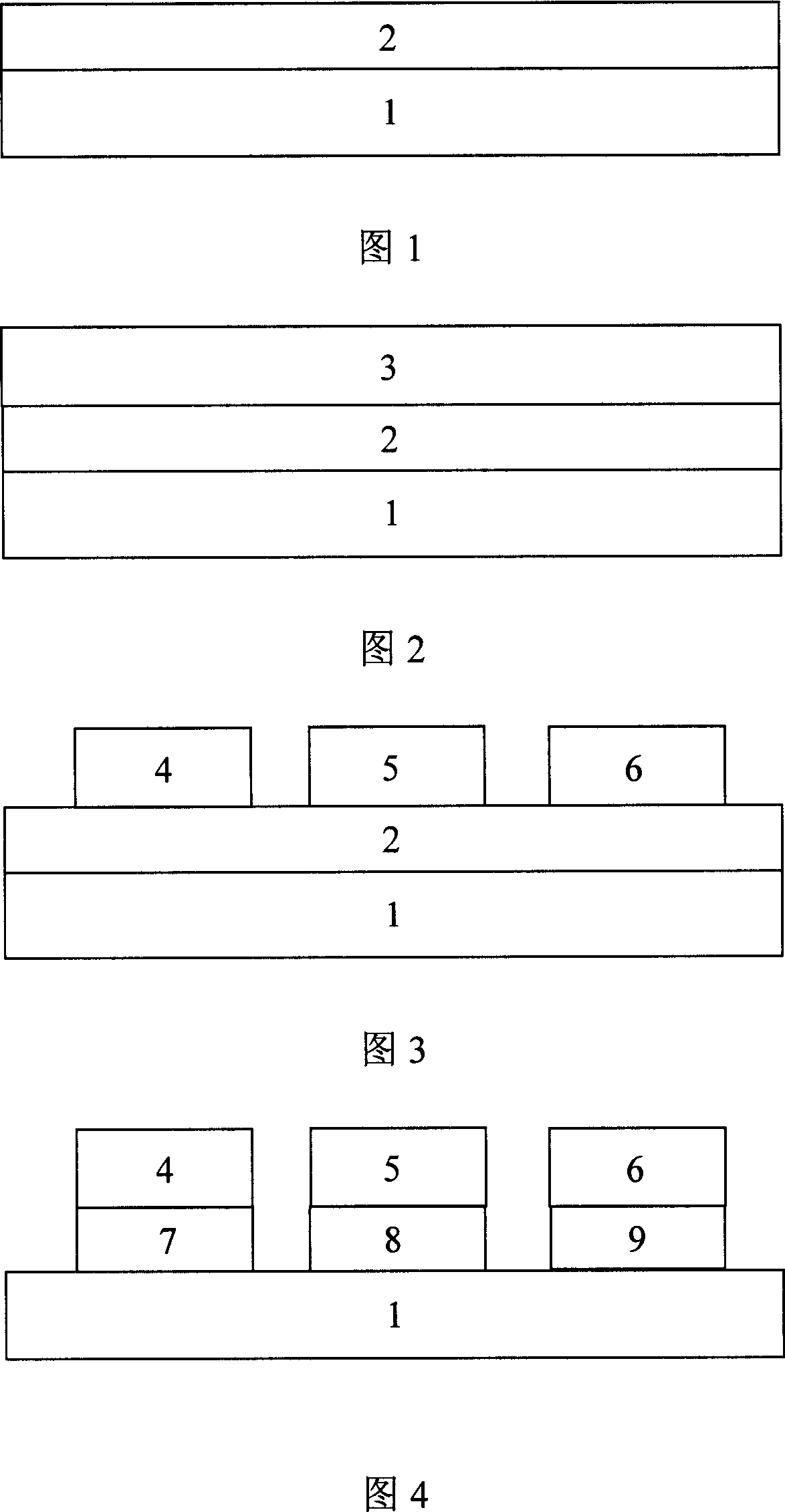

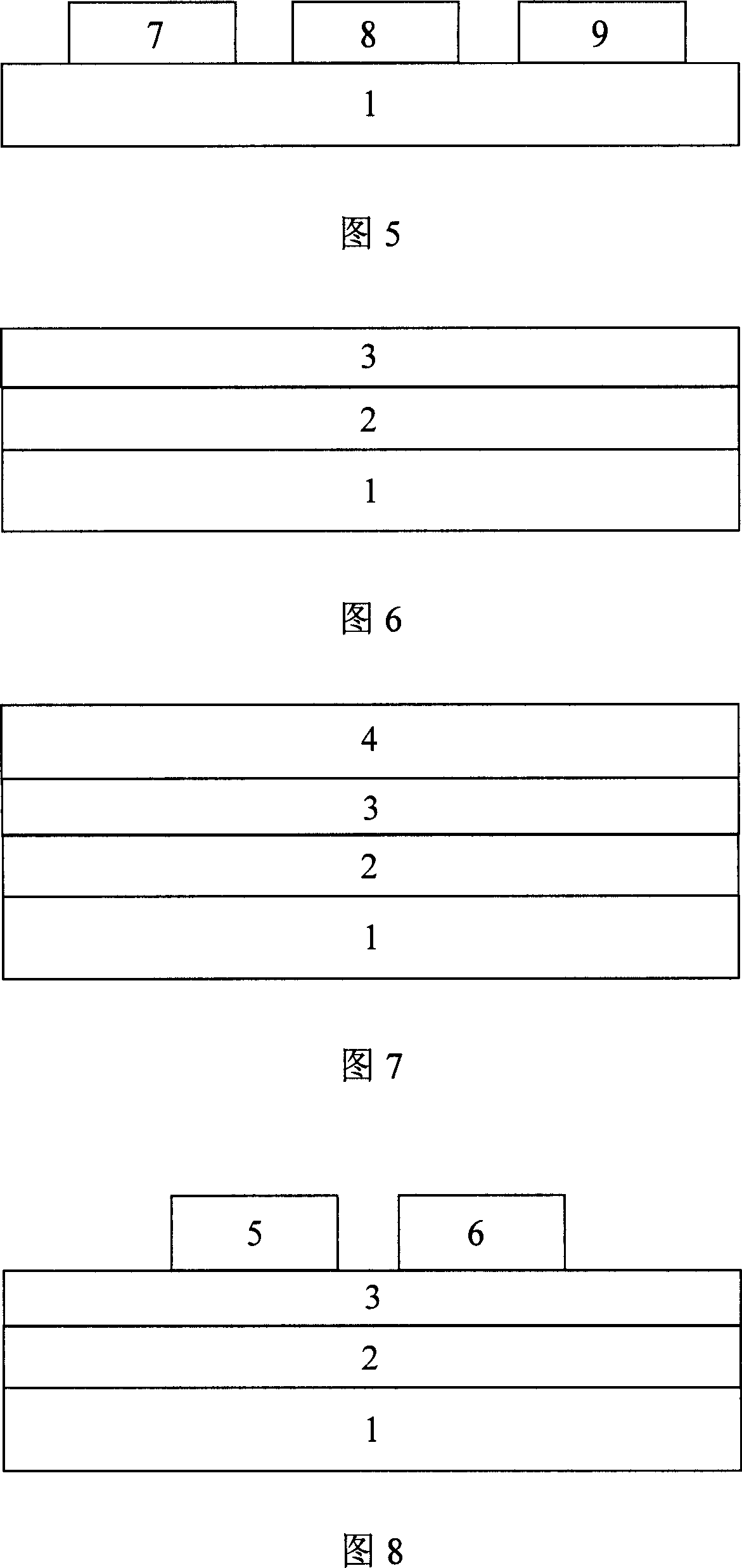

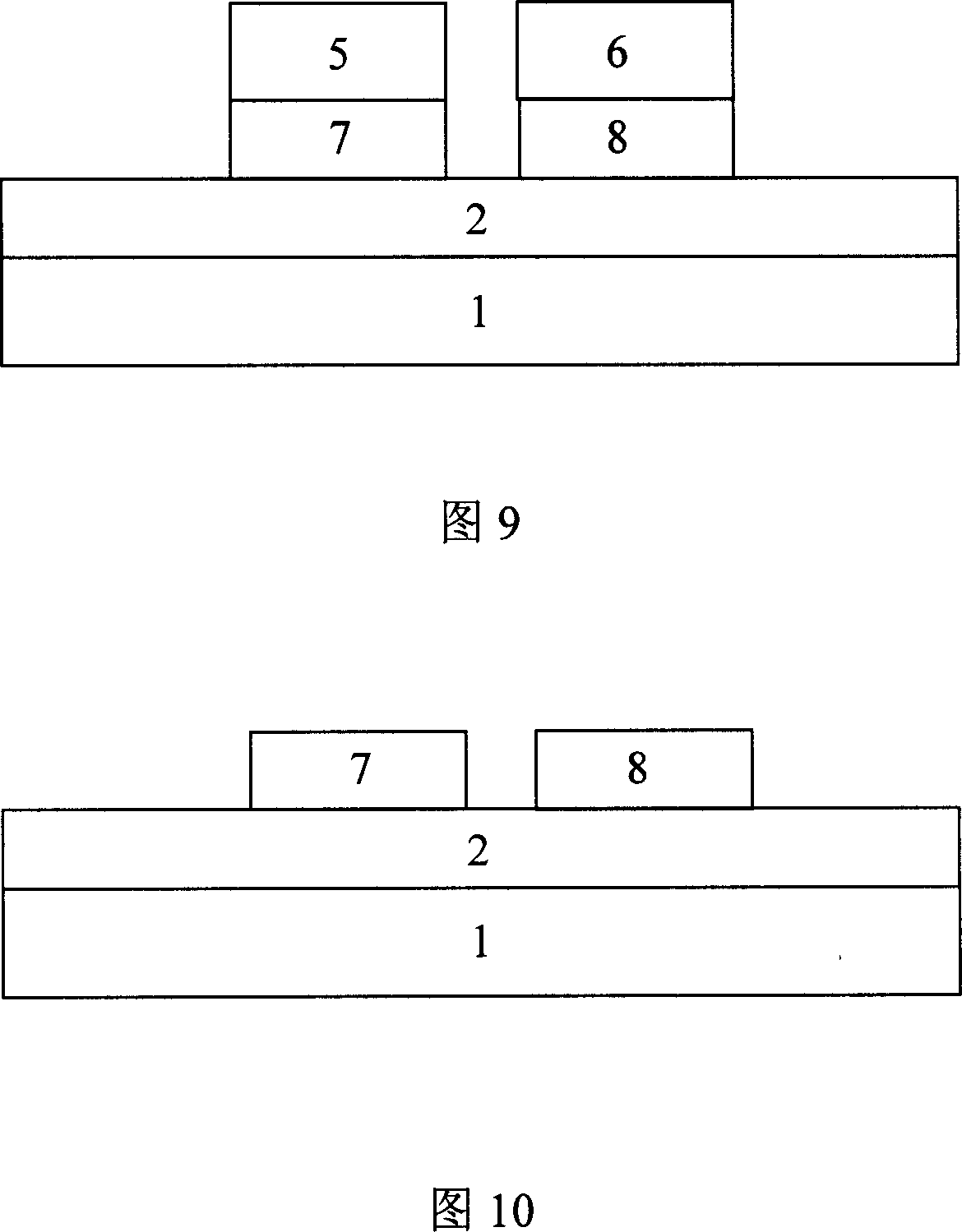

[0029] Taking the use of SOI substrate, SAL601 chemically amplified negative electronic resist, and ICP etching as an example, the detailed process and steps of the present invention are further described in conjunction with the accompanying drawings, wherein:

[0030] As shown in Figure 6, a p-type, (111) crystal-oriented SOI substrate is used, and the SOI substrate is composed of a silicon base 1, a 375nm-thick buried oxide layer 2, and a 50nm-thick top layer silicon 3 from bottom to top. constitute. P 31+ ions, the implantation energy is 20keV, and the implantation dose is 1×10 15 cm -2 , then at N 2 Rapid annealing at 1200° C. for 10 seconds in an atmosphere improves the conductivity of the top layer silicon 3 .

[0031] As shown in FIG. 7 , SAL601 chemically amplified negative electronic resist 4 was coated on the SOI substrate with a coater, the coating speed was 3000 rpm, and the coating time was 60 seconds. Then pre-bake at 110° C. for 3 minutes with a hot plate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com