Organosilicon electronic encapsulation material

A potting material and silicone technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of poor mechanical properties of cured products, unsuitable for electronic potting, etc., to achieve effective packaging, prolong service life, and make The effect of simple craftsmanship and flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

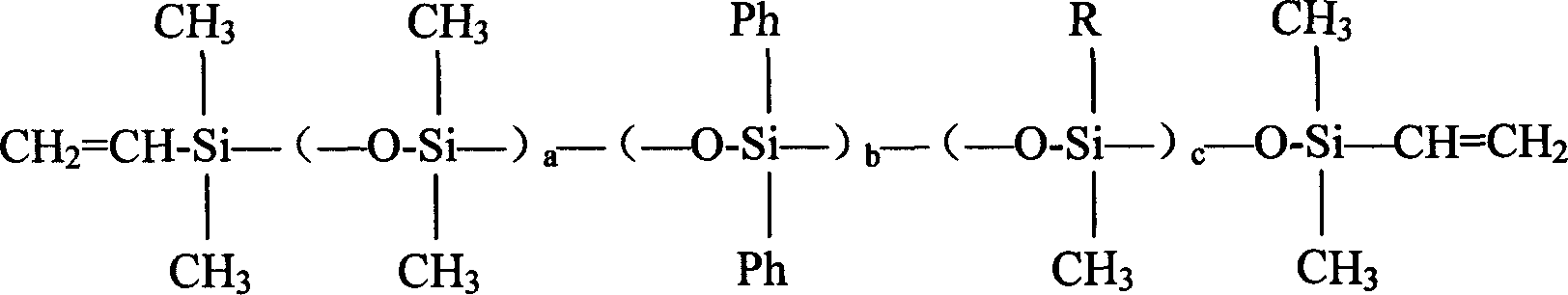

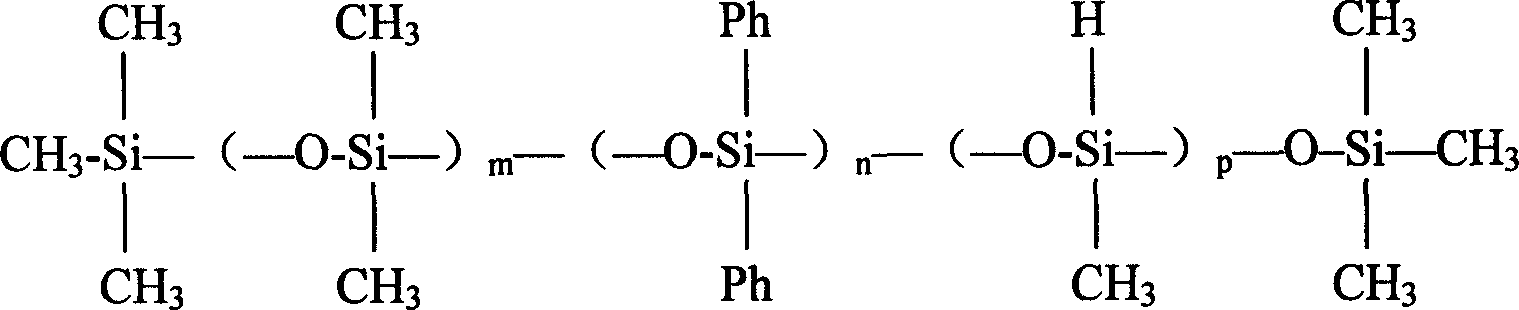

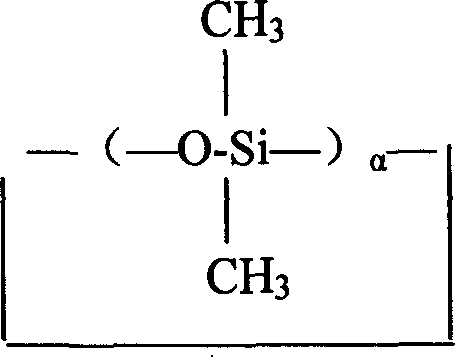

Method used

Image

Examples

example 1

[0033] Get a clean 500ml three-necked bottle, add octamethylcyclotetrasiloxane 100g therein, octaphenylcyclotetrasiloxane 50g, and the structural formula is (CH 2 =CH)(CH 3 ) 2 SiOSi (CH 3 ) 2 (CH=CH 2 ) end-capping agent 2g, potassium siloxanate catalyst 0.1g, after stirring and reacting at 160~180°C for 8 hours, add (Me 3 SiO) 2 OHP=O to neutralize until it is neutral, then remove low boilers under vacuum; cool to room temperature, and filter to obtain colorless and transparent vinyl-terminated polymethylphenylsiloxane with a viscosity of 1100mpa· S (25°C).

[0034] Take 100g of the above-mentioned vinyl-terminated polymethylphenylsiloxane, and then take 10g of polymethylhydrophenylsiloxane with a viscosity of 100mpa S (25°C), and a viscosity of 800mpa S (25°C). 20g silicone resin, 0.2g platinum catalyst coordinated by methylvinylsiloxane, 0.15g methylpentynol, stir evenly, remove foam, pour into a mold of 2mm×13mm×13mm, and bake at 150°C Bake for 1 hour to form into...

example 2

[0036] Get a clean 500ml three-necked bottle, add octamethylcyclotetrasiloxane 100g therein, octaphenylcyclotetrasiloxane 100g, and the structural formula is (CH 2 =CH)(CH 3 ) 2 SiOSi (CH 3 ) 2 OSi(CH 3 ) 2 (CH=CH 2 ) end-capping agent 2g, potassium siloxanate catalyst 0.1g, after stirring and reacting at 160~180°C for 8 hours, add (Me 3 SiO)(OH) 2 P=O neutralization until neutrality, remove the low boilers under vacuum; cool to room temperature, filter to obtain colorless and transparent vinyl-terminated polymethylbenzene with a viscosity of 1300mpa·S (25°C) base siloxane.

[0037] Take 100g of the above-mentioned vinyl-terminated polymethylphenylsiloxane, then take 15g of polymethylhydrophenylsiloxane with a viscosity of 100mpa S (25°C), and vinyl with a viscosity of 600mpa S (25°C). 30g of methyl silicone resin, 0.3g of tetrahydrofuran-coordinated platinum catalyst, 0.15g of methyl pentynol, stir evenly, defoam, pour into a mold of 2mmx13mmx13mm, bake at 150°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com