Process for preparing gold nano particle by using aqueous phase soft mould plate method

A soft template method and nanoparticle technology, which is applied in the field of preparing gold nanoparticles by the aqueous phase reduction process, can solve the problems of difficult product separation, easy side reactions, and easy pollution, and achieve cost reduction, less impurities, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

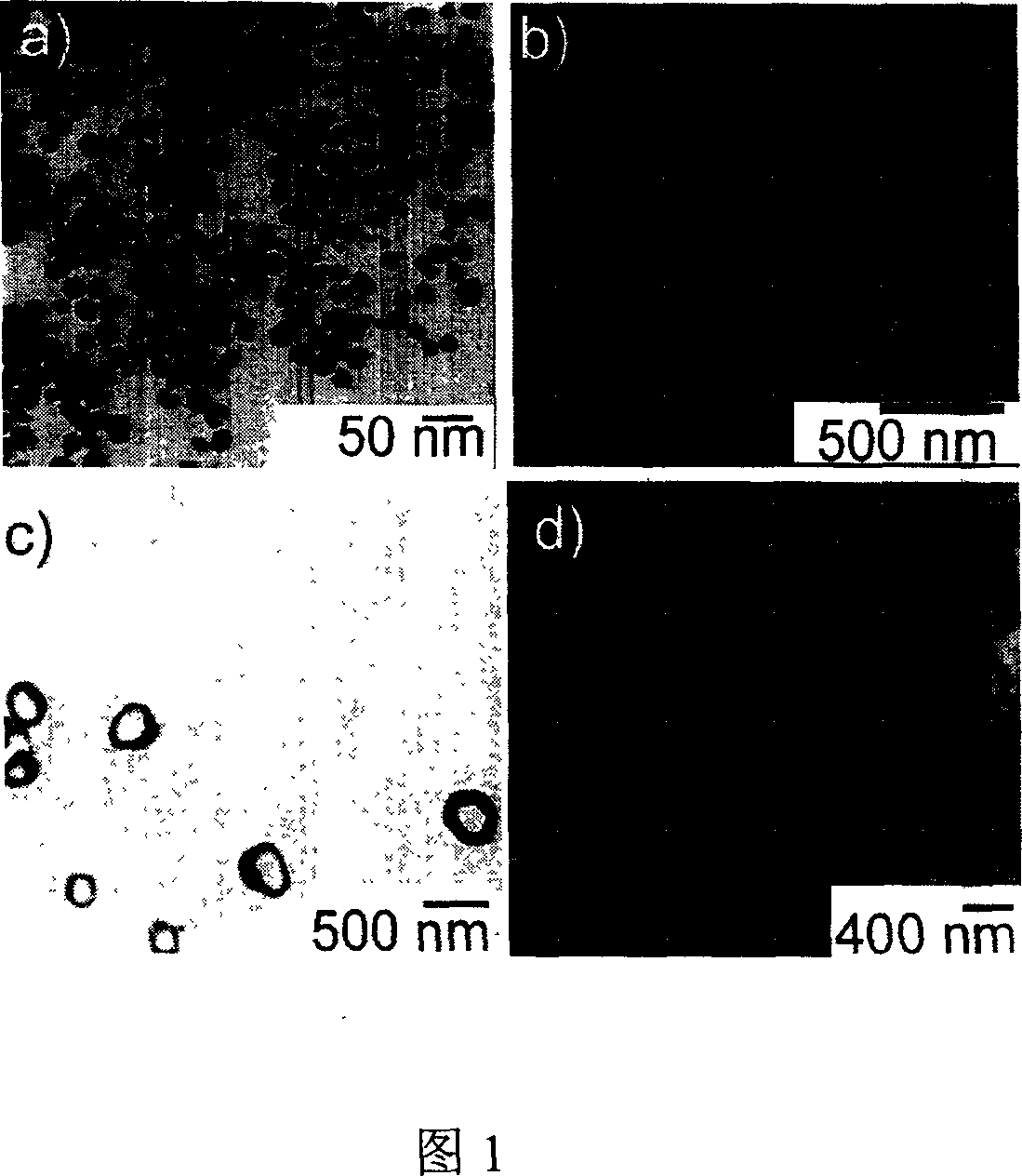

[0015] Embodiment 1 SDS-PEG (PEG average molecular weight 8000) soft template synthesis of gold nanospheres.

[0016] Add a certain amount of PEG and SDS to deionized water, heat to 40-60°C to fully dissolve and self-assemble into soft clusters, and mix with the aqueous solution containing chloroauric acid after the solution is cooled to room temperature, so that each The final concentrations of the components are respectively: 0.1 mmol / L of chloroauric acid, 60 g / L of PEG, and 5 mmol / L of SDS. After stirring for about 1min (400r / min) at room temperature and normal pressure, react at around room temperature (25±1)°C in the dark for 2-6h. After the reaction, the reaction solution was centrifuged with a high-speed centrifuge (10000r / min) to separate the product, and the precipitate was washed three times with deionized water to obtain spherical gold nanoparticles with an average particle size of 20±5nm.

Embodiment 2

[0017] Example 2 SDS-PEG (PEG average molecular weight: 20,000) soft template was used to synthesize gold nanosheets.

[0018] Add a certain amount of PEG and SDS to deionized water, heat to 40-60°C to fully dissolve and self-assemble into soft clusters, and mix with the aqueous solution containing chloroauric acid after the solution is cooled to room temperature, so that each The final concentrations of the components are respectively: 0.5mmol / L of chloroauric acid, 85g / L of PEG, and 10mmol / L of SDS. After stirring for about 1min (400r / min) at room temperature and normal pressure, react at around room temperature (25±1)°C in the dark for 24-48h. After the reaction, the reaction solution was centrifuged with a high-speed centrifuge (3000r / min) to separate the product, and the precipitate was washed three times with deionized water to obtain gold nanosheets with an average diameter of 500±50nm.

Embodiment 3

[0019] Example 3 Synthesis of gold nanorings using SDS-PEG (average PEG molecular weight: 10,000) soft template.

[0020] Add a certain amount of PEG and SDS to deionized water, heat to 40-60°C to fully dissolve and self-assemble into soft clusters, and mix with the aqueous solution containing chloroauric acid after the solution is cooled to room temperature, so that each The final concentrations of the components are respectively: 0.3mmol / L of chloroauric acid, 120g / L of PEG, and 3mmol / L of SDS. After stirring at room temperature and normal pressure for about 1min (400r / min), react at around room temperature (25±1)°C in the dark for 180-240h. After the reaction, the reaction solution was centrifuged with a high-speed centrifuge (3000r / min) to separate the product, and the precipitate was washed three times with deionized water to obtain gold nanorings with an average diameter of 500±50nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com