Material supplying device and method

A technology of supplying device and stirring device, which is applied in the direction of assembling printed circuits, electrical components, circuits, etc. with electrical components, can solve the problems of reduced mechanical strength of metal masks, difficult-to-solder particles supplying workpieces, and paste soldering material falling off, etc. Achieve high-precision and non-fluctuation quantitative discharge, shorten processing time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

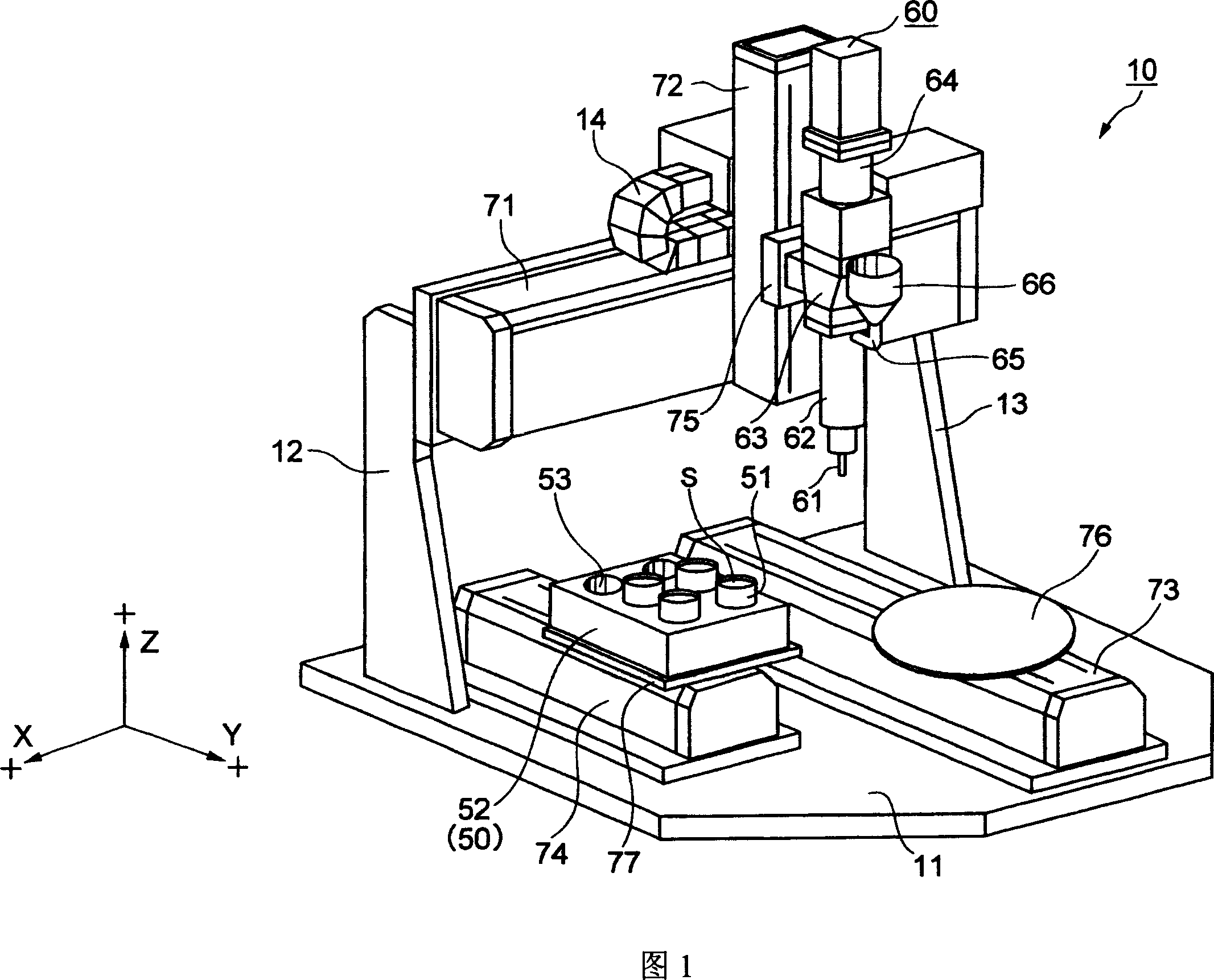

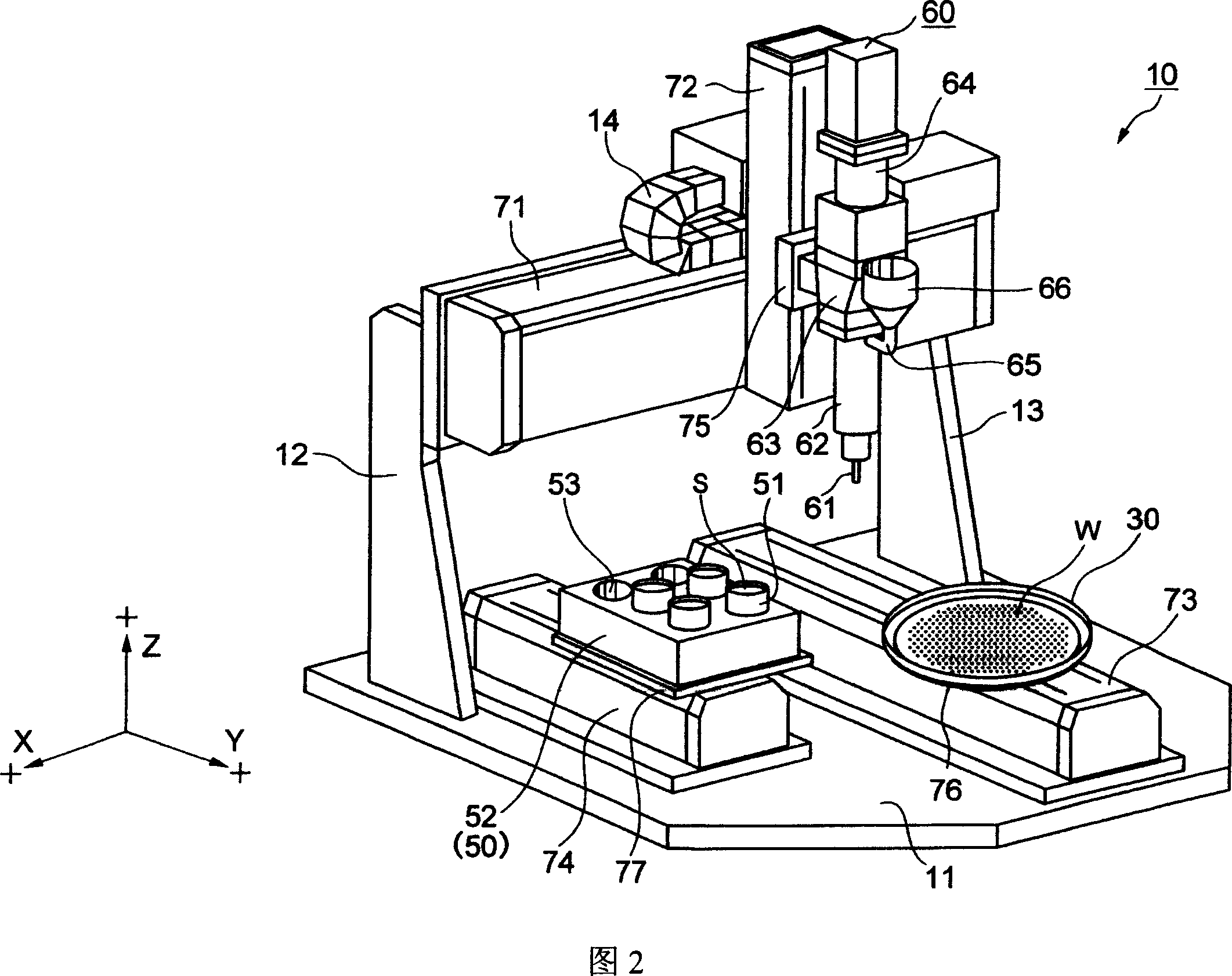

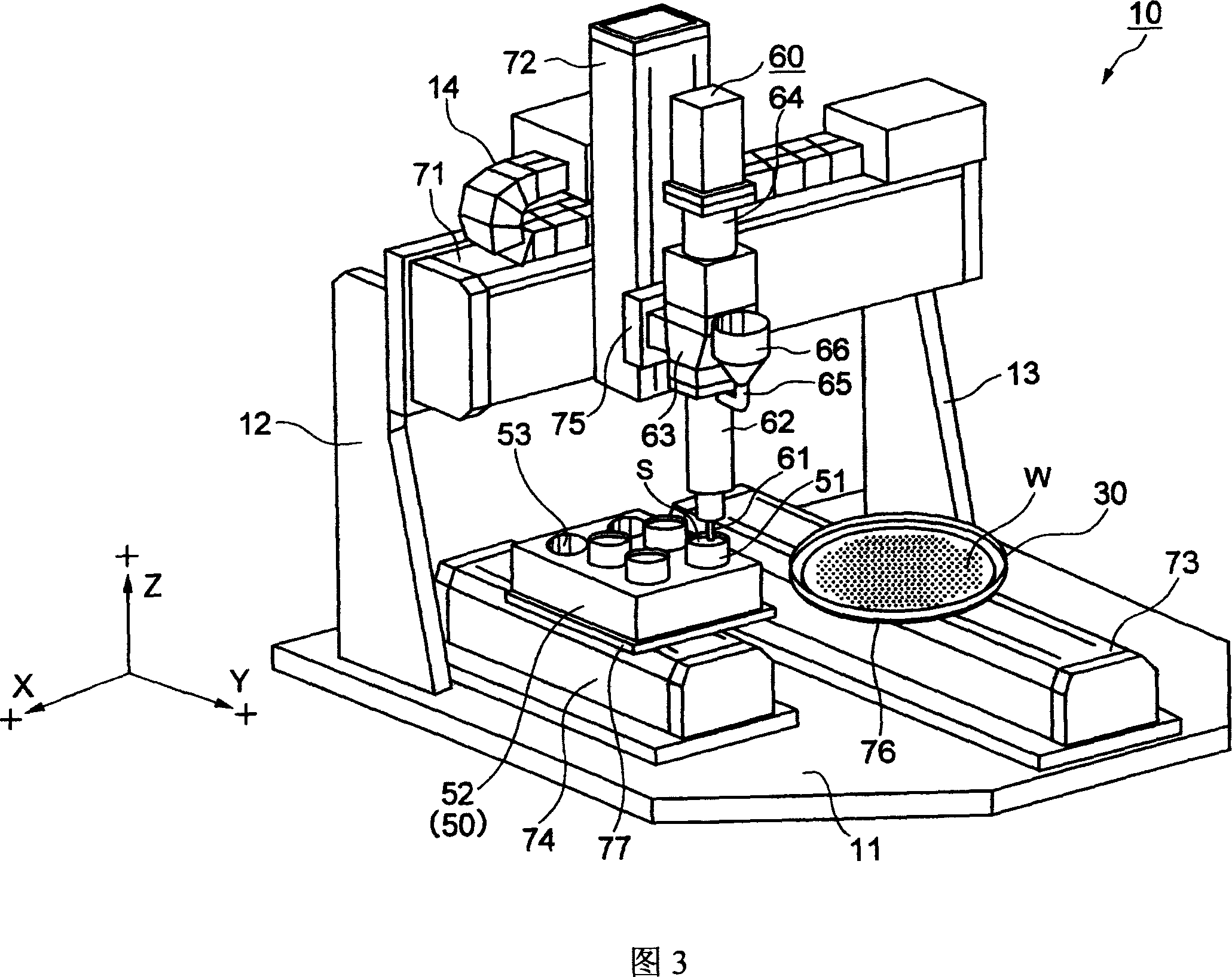

[0042] Embodiments of the present invention will be described below with reference to the drawings.

[0043] 1 to 4 are perspective views showing embodiments of the solder material supply apparatus and method of the present invention, and the steps are performed in the order of FIG. 1 → FIG. 2 → FIG. 3 → FIG. 4 → FIG. 1 . . . Hereinafter, it demonstrates based on these figures. However, since the liquid and solder particles forming the solder material are not shown in the figure, please refer to FIG. 6 and the like.

[0044] In the embodiments of the present invention, solder particles are used as solid particles, liquid having a flux function as liquid, solder material as material, a magnetic stirrer (Magneticus stra) as a stirring device, and a uniaxial eccentric screw pump (hereinafter A dispenser) will be described as an example as a supply device or a pump, and a sub-tank as a storage device.

[0045] First, the structural features, functions, and effects of the solder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com