Process of recovering ethylene and methane from emptying end gas of glycol apparatus

A ethylene glycol and tail gas technology, applied in organic chemistry, membrane purification/separation, etc., can solve the problems of polluting the environment, increasing production costs, wasting resources, etc., achieving simple operation, reducing raw material consumption, and small maintenance workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

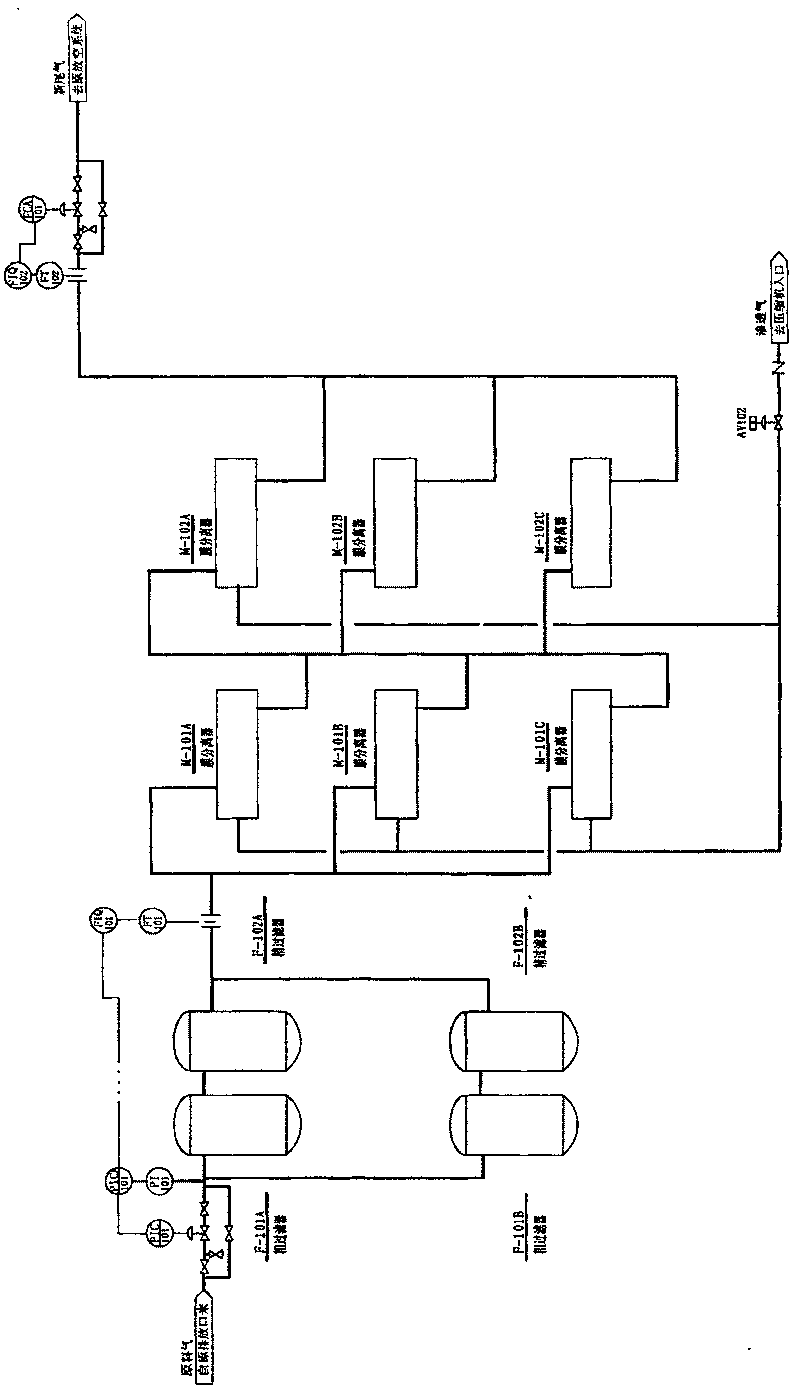

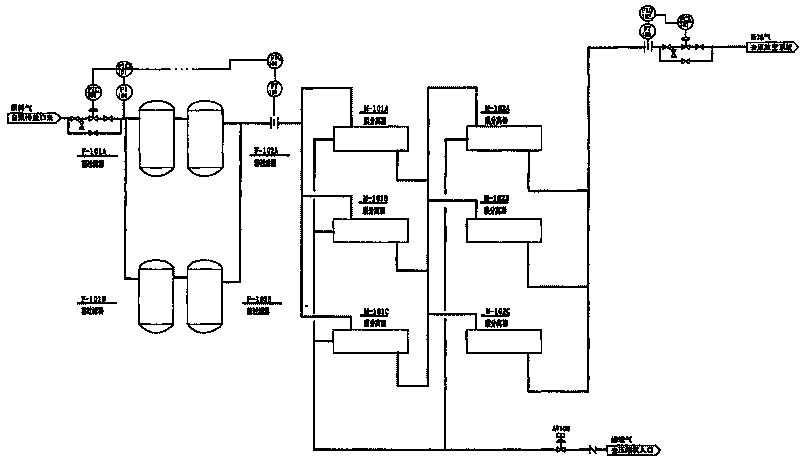

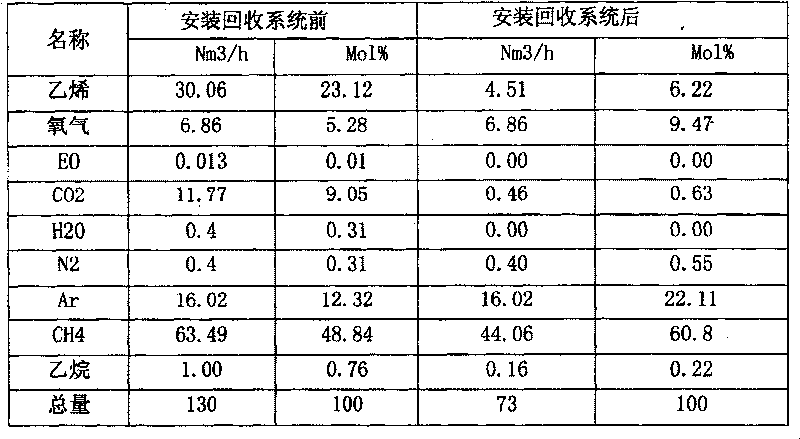

[0008] As shown in the figure, take the 100,000 tons / year ethylene glycol production plant as an example to implement the present invention, the equipment of the existing plant need not be changed, only need to increase the corresponding equipment. Raw material gas is the tail gas discharged from the original discharge port before the reformation of the ethylene glycol plant. After the present invention is provided with coarse filter F-101A, B, 40 mesh, the inlet temperature is 90 ℃ ~ 100 ℃, its inlet pressure (absolute Pressure, hereinafter all the same) is 1.8 ~ 1.9MPa, and then through the fine filter F-102A, B, through the 60 mesh net, further remove granular impurities, to prevent poisonous membrane separator, the membrane separation is divided into two stages, with a First-stage membrane separator M-101A, B, C, second-stage memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com