Gasoline alkylation desulfuration method

An alkylation desulfurization and gasoline technology, which is applied in the field of hydrocarbon oil refining and desulfurization, can solve problems such as the difficulty in regeneration of acidic ionic liquids, and achieve the effects of easing operating conditions, suppressing side reactions, and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

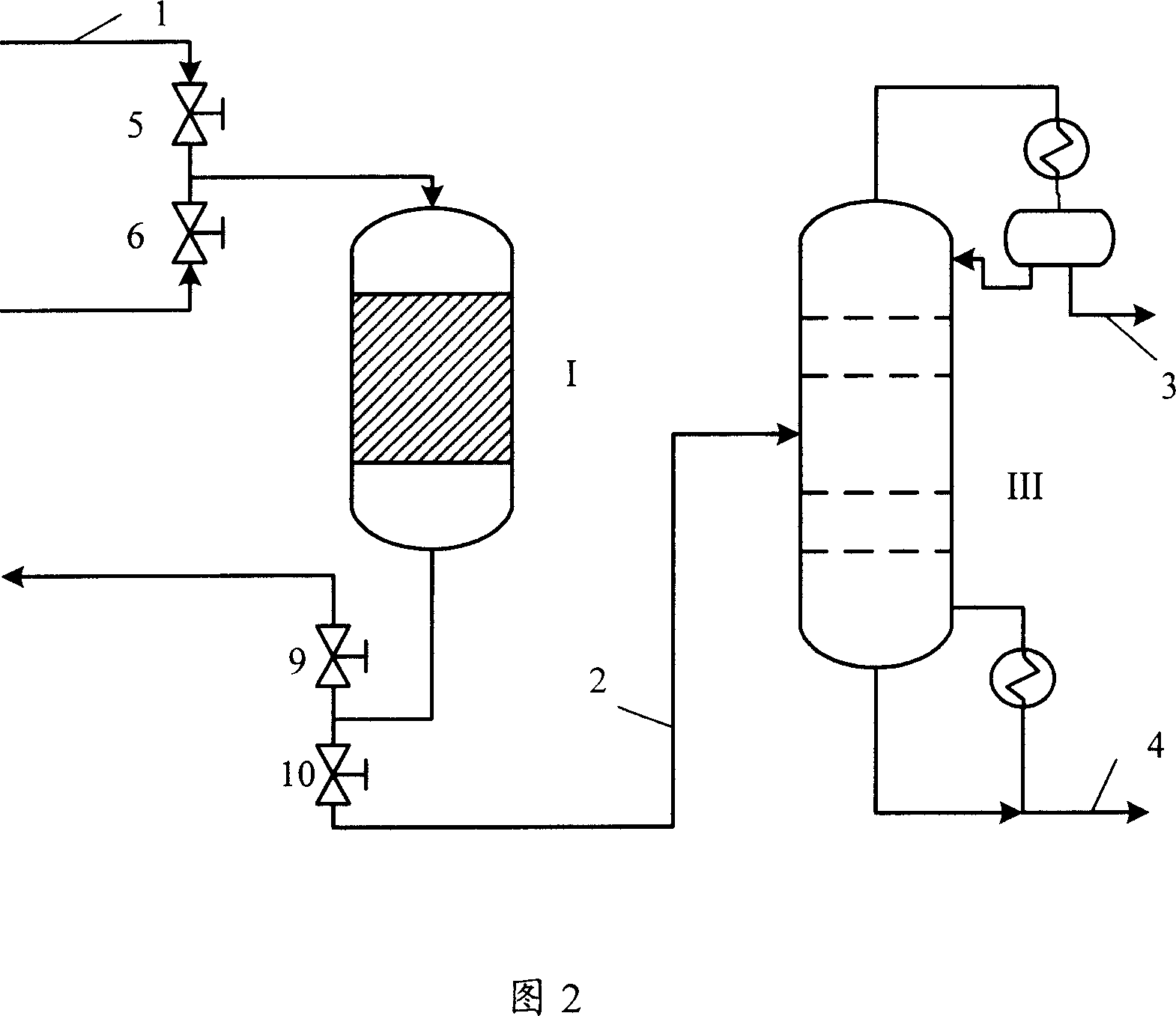

[0030] This embodiment is a single reactor process, the schematic diagram of which is shown in Figure 2.

[0031] The inner diameter of the reactor is 100 mm, and the height is 1 meter. Fill 250 g of ZnCl in the fixed bed reactor 2 Ion-exchange resin catalyst A, the physical properties of the catalyst are shown in Table 1, and the temperature of the catalytic cracking gasoline is 80°C, and the liquid hourly space velocity is 3.0h -1 , the pressure is to react under the condition of 0.5MPa, the distillation range of the raw material is shown in Table 2, and simultaneously feed H 2 Keeping the reaction pressure, the reaction product is passed into the fractionation tower, where it is cut into light fraction and heavy fraction at 110°C. The output ratio of tower top and tower bottom is 7:3. The distribution of sulfur compounds in raw materials, light fraction and heavy fraction is shown in Table 3, the light fraction and the heavy fraction are mixed according to the output ratio...

Embodiment 2

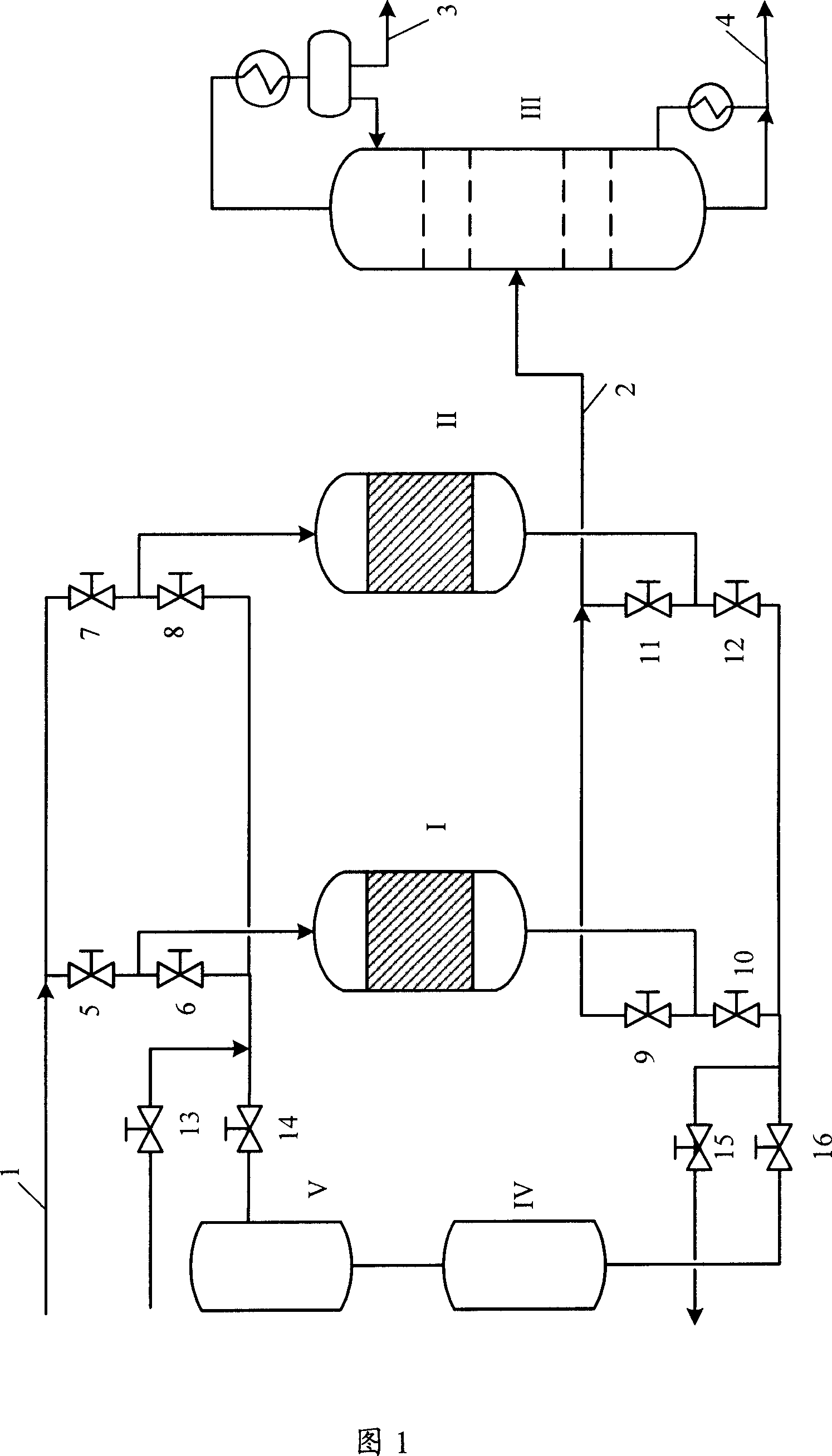

[0033] This embodiment is a flow process of two reactors, the schematic diagram of which is shown in FIG. 1 .

[0034] Reactor and fractionating tower are the same as embodiment 1, in fixed bed reactor, packing contains AlCl 3 The ion-exchange resin catalyst B, catalyst physical property is shown in Table 1, feeds the catalytic cracking gasoline raw material identical with embodiment 1, feeds N simultaneously 2 Keep the reaction pressure, when the reaction temperature is 80°C, the liquid hourly space velocity is 6.0h -1 , the reaction is carried out under the condition of 1.0MPa pressure, and the reaction product is passed into the fractionation tower, and is cut into light fraction product and heavy fraction at 155°C, the output ratio of tower top and tower bottom is 8:2, raw material, light fraction and heavy fraction The distribution of sulfur compounds in the heavy fraction is shown in Table 3. The light fraction and the heavy fraction are mixed according to the output ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com