Natural travertine-imitated ceramic brick and making method

A porcelain tile, natural imitation technology, applied in the field of porcelain tile production, can solve the problems of high price, unnatural effect, limited resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

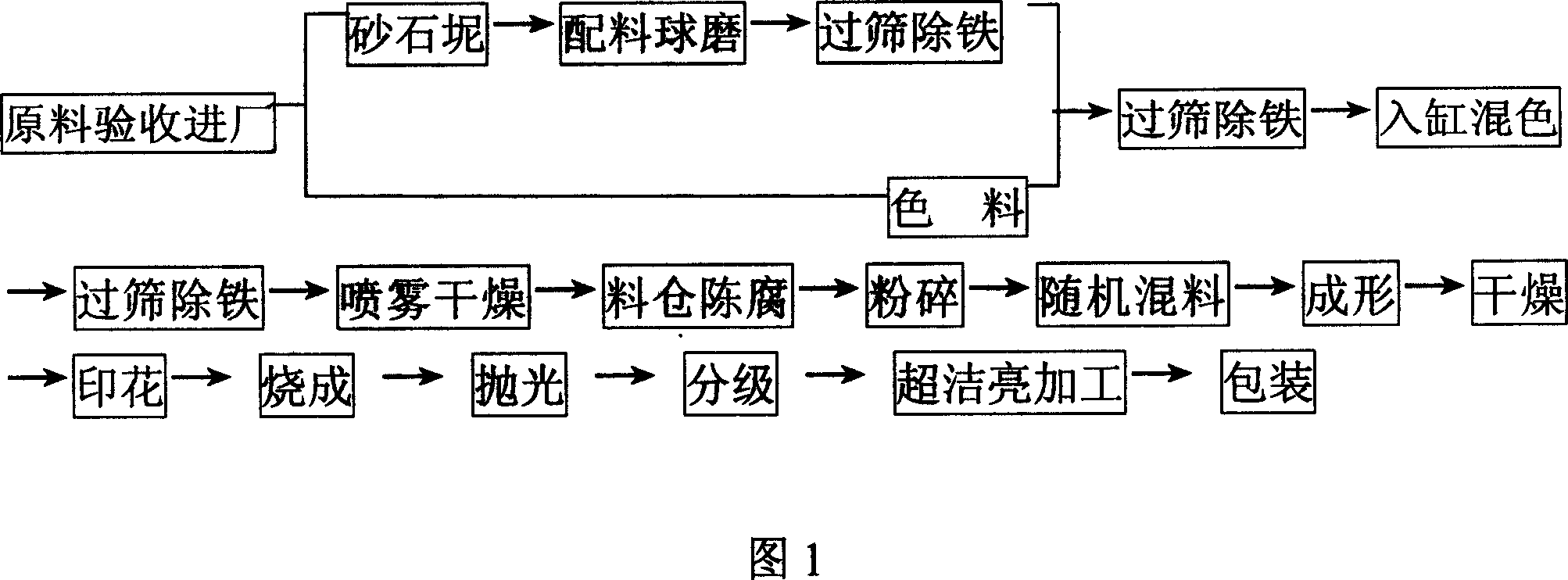

Method used

Image

Examples

example 1

[0026] White material formula (No. CB-13):

[0027] Raw material name Proportion (%)

[0028] Ball soil 1# 16

[0029] Ball soil 2# 9

[0030] Albite 1# 10

[0031] Albite 2# 17

[0032] Albite 3# 16

[0033] Potassium feldspar 1# 3

[0034] Potassium feldspar 2# 3

[0035] Potassium feldspar 3# 7

[0036] High temperature sand 1# 9

[0037] High temperature sand 2# 5

[0038] High temperature sand 3# 3

[0039] burnt talc 2

[0040] Total 100

[0041] Foaming material formula (No. QP-01):

[0042] Raw material name Proportion (%)

[0043] Lithium feldspar 38

[0044] limestone 17

[0046] Albite 2 22

[0047] Ball soil 1# 10

[0048] burnt talc 1

[0049] Total 100

[0050] The actual chemical composition of the above two formulations is shown in Table 4.

[0051] Table 4 Formula Chemical Composition Table

[0052] recipe name

SiO 2

al 2 o 3

Fe 2 o 3

TiO 2

CaO

MgO

K 2 o

Na ...

example 2

[0073] White material formula (No. CB-13).

[0074] Foaming material formula (No. QP-02):

[0075] Raw material name Proportion (%)

[0076] Lithium feldspar 40

[0077] limestone 17

[0079] Albite 2# 27

[0080] Ball soil 1# 10

[0081] burnt talc 1

[0082] Total 100

[0083] The process parameters of color matching and proportioning are as follows:

[0084] (1), color matching

[0085] Material D: CB-13 (dry material) 100g + 0.6g jade yellow + 3# black material 0.04g + orange red 0.15g

[0086] CB-04 material: CB-13 (dry material) 100 grams + zirconium silicate 2.0 grams

[0087] (two), fabric ratio:

[0088] 1# pipe (1# groove) D material (dark brown material) 10

[0089] 2# pipe (2# tank) D material 20%+CB-04 80% (white material) 25

[0090] 3# pipe (3# groove) QP-02 material 5

[0091] 4# pipe (4# tank) D material 70% + CB-04 30% (light brown material) 60

[0092] Other parameters are the same as "Example 1".

[0093] It is base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com