Preparation method of modified turf adsorbent

A technology of modified peat and adsorbent, which is applied in chemical instruments and methods, adsorption water/sewage treatment, energy wastewater treatment, etc. Problems such as large land area, to achieve the effect of process production and economic benefit improvement, mechanical strength and stability enhancement, and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of modified peat adsorbent:

[0032] Pre-treatment of peat soil: The raw materials used are: natural peat. The natural peat is dried, sun-dried or air-dried, and the sundries are detected separately, and crushed into 40-mesh granules for later use.

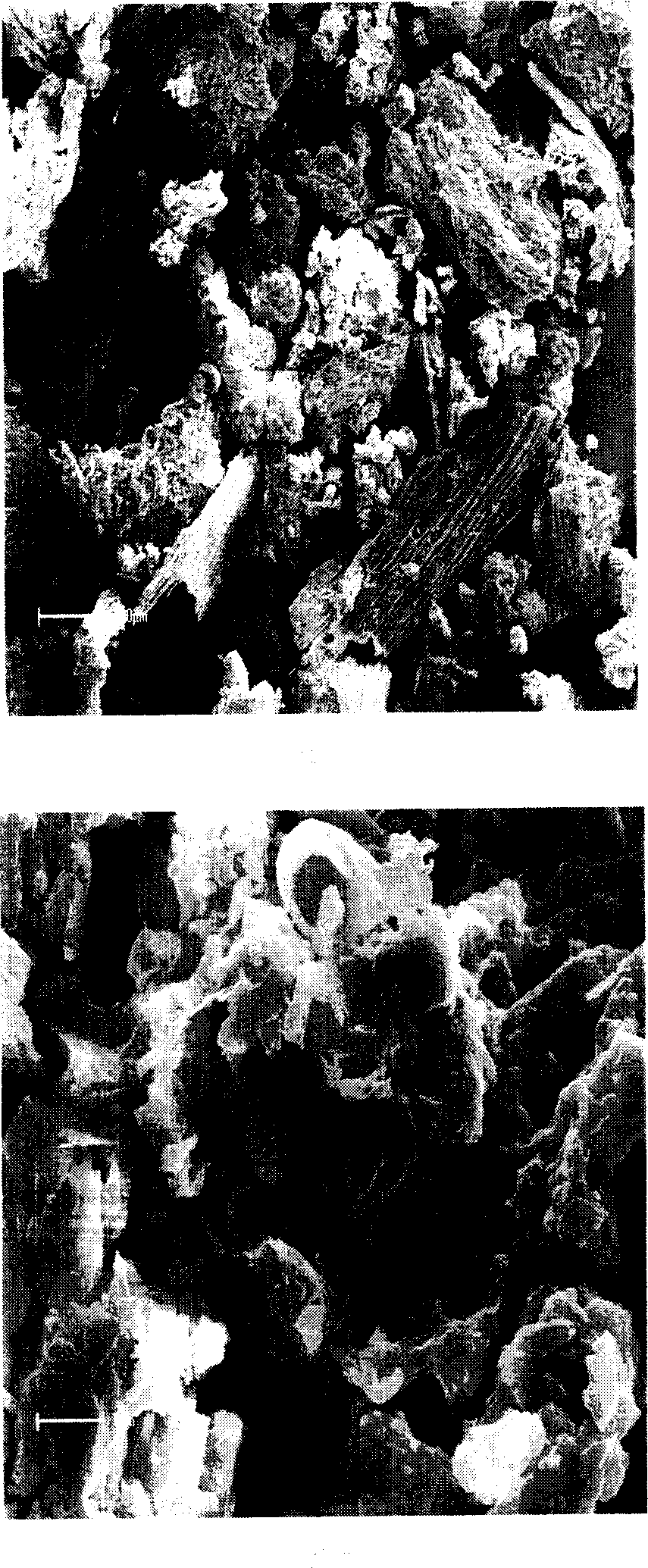

[0033] Preparation method: Use 1mol / L NaOH to neutralize the peat (PS) sample to pH = 10.0, then use 0.1mol / L NaOH to adjust the liquid-solid ratio to 1:1, stir at room temperature for 24 hours, and centrifuge, the sediment is peat for the first time The remaining substance after extraction is the alkali-treated modified peat adsorbent (APS1). After drying the APS1, it is ground through a 60-mesh sieve for later use. It is tested with 60-mesh peat to treat heavy metal wastewater under constant stirring. The microstructure of PS and APS1 after adsorbing heavy metals was observed by scanning electron microscope.

[0034] Simulated initial concentration of heavy metal wastewater: Cd: 5.6mg / L, Pb: 41.4mg / L, Cu: 12...

Embodiment 2

[0051] The difference from Example 1 is:

[0052] Preparation of modified peat adsorbent:

[0053] Pre-treatment of peat soil: Peat is crushed into 60-mesh particles for later use.

[0054] Preparation method: Use 1mol / L KOH to neutralize the peat sample to pH = 11, then use 0.1mol / L NaOH to adjust the liquid-solid ratio to 10:1.

[0055] Preparation of another modified peat adsorbent: use 1mol / L KOH to neutralize the peat sample to pH = 11, then use 0.1mol / L NaOH to adjust the liquid-solid ratio to 10:1, static separation, and the separated supernatant , with 6mol / LH 2 SO 4 Adjust its pH value to make it pH=3.

Embodiment 3

[0057] The difference from Example 1 is:

[0058] Preparation of modified peat adsorbent:

[0059] Pre-treatment of peat soil: Peat is crushed into 80-mesh particles for later use.

[0060] Preparation method: Use 1mol / L soda lime to neutralize the peat sample to pH = 11, then use 0.1mol / L NaOH to adjust the liquid-solid ratio to 50:1.

[0061] Preparation of another modified peat adsorbent: use 1mol / L soda lime to neutralize the peat sample to pH = 11, then adjust the liquid-solid ratio to 50:1 with 0.1mol / L NaOH, separate statically, and separate the supernatant liquid, with 6mol / LHNO 3 Its pH was adjusted to make it pH=3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com