Biodegradable imaging microspheres vascular embolization material

A biodegradable material and a biodegradable technology are applied in the field of biodegradable imaging microsphere vascular embolization materials, which can solve the problems of affecting long-term curative effect, prone to false embolization, difficult operation, etc., achieving good positioning, avoiding false embolization, good visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

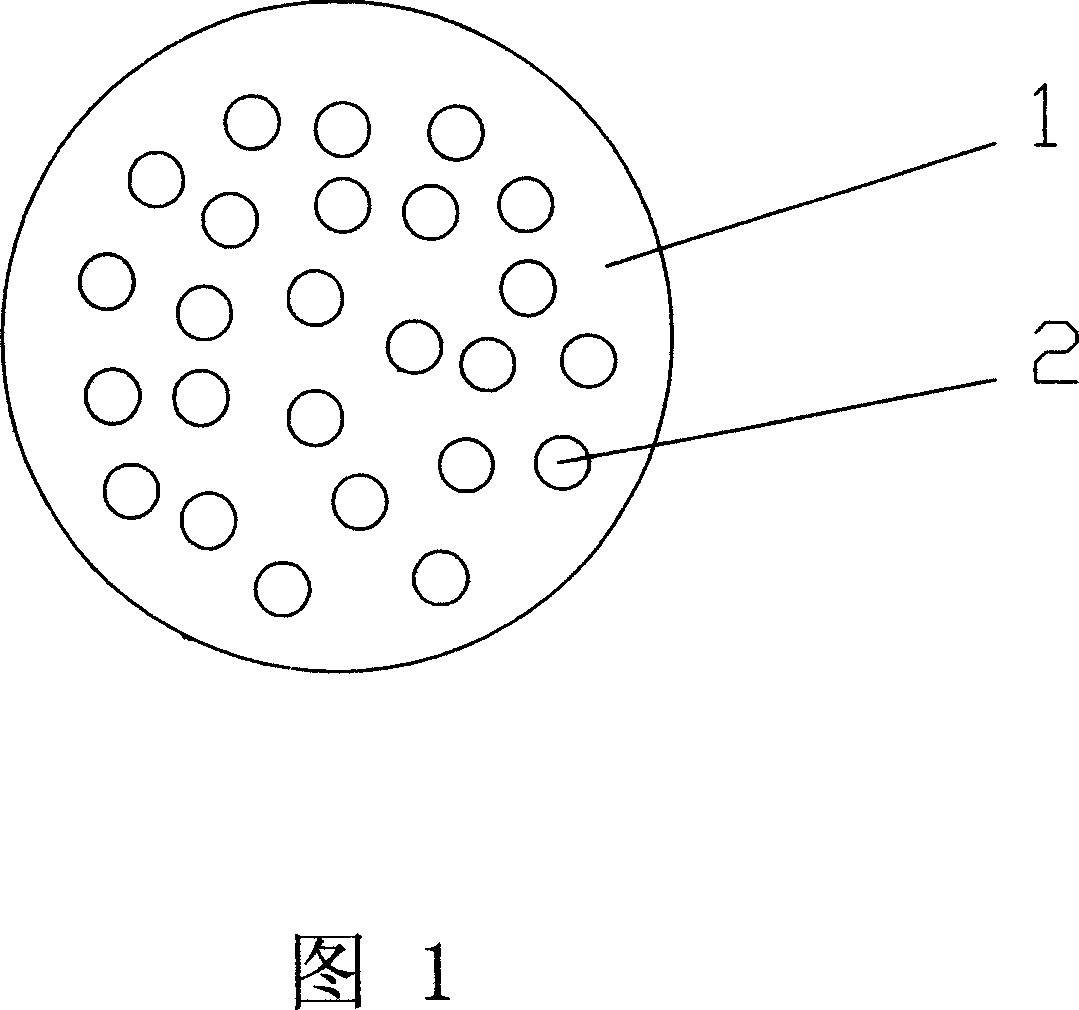

[0015] Example 1: The developed polylactic acid (PLA) microspheres of the present invention

[0016] An angiographic contrast agent, such as the ionic contrast agent Urografin, is purchased on the market, after being processed by a vacuum freeze-drying method, the remaining material after freeze-drying is retained as a developing material (2).

[0017] The use of polylactic acid as the biodegradable material (1) and the general process of manufacturing drug-containing microspheres according to the polylactic acid as the packaging material of various drugs can conveniently manufacture the developing material (2) microspheres.

[0018] Polylactic acid is used as a packaging material for various drugs to manufacture drug-containing microspheres, and there have been many general processes. For example, Yang Fan et al. published "Study on the Preparation Technology of Ciprofloxacin Polylactic Acid Microspheres" in "Journal of China Pharmaceutical University, 2004, 35(3):207-210". Prepa...

Embodiment 2

[0022] Example 2: Developed polylactic acid glycolic acid copolymer (PLGA) microspheres of the present invention

[0023] The production method of the product of this embodiment is basically the same as that of embodiment 1, except that the biodegradable material (1) is selected as polylactic acid glycolic acid copolymer, and the developing material (2) can be selected from one of the following substances: The remaining substance after vacuum freeze-drying of the contrast agent diatrizoate meglumine; the non-ionic contrast agent Iohexol (Iohexol) or iopromide (Iopromide) or Iopamidol is processed by vacuum freeze-drying The remaining substance after the treatment; the remaining substance after the non-ionic dimer Iotrolan and other angiographic contrast agents are processed by the vacuum freeze-drying method.

[0024] Both the developed PLA microspheres and the developed PLGA microspheres of the present invention are prepared by the emulsification dispersion method and the phase s...

Embodiment 3

[0025] Example 3: The developed polycaprolactone-polyglycolide-polyglycolide copolymer microspheres of the present invention

[0026] The production method of the product of this embodiment is basically the same as that of embodiment 1, except that the biodegradable material (1) is selected as polycaprolactone-polyglycolide-polyglycolide copolymer, and the developing material (2) can be One of the following substances: the remaining substance after the ionic contrast agent diatrizoate meglumine is processed by vacuum freeze-drying; the non-ionic contrast agent Iohexol or Iopromide or Iopromide Iopamidol is the remaining material after vacuum freeze-drying; non-ionic dimer Iotrolan and other angiographic contrast agents are vacuum-freeze-dried. Use general emulsification dispersion method and phase separation coagulation method to prepare microspheres or CO 2 New supercritical fluid technology to prepare microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com