Electromagnetic four-way valve main valve seat processing method

A processing method and four-way valve technology, applied in the direction of multi-way valves, valve devices, engine components, etc., can solve the problems of molecular crystals not being firmly connected, the main valve seat losing the closed cavity, and affecting the normal use of the product, so as to achieve saving Effects of materials, product cost reduction, and molecular bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

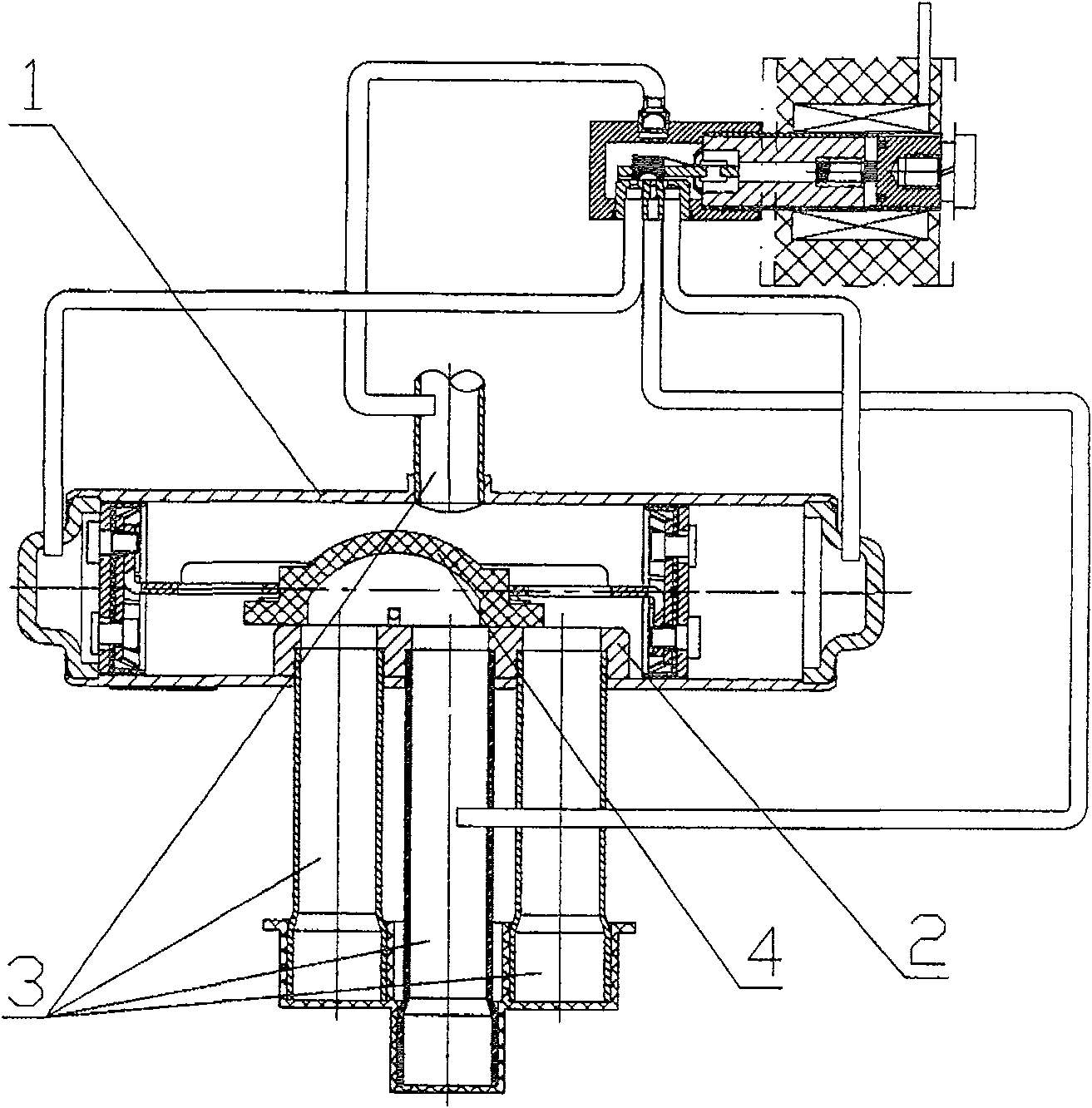

[0031] like figure 1 , 2 As shown in , 3, the main valve seat 2 is welded on the main valve body 1, and the connecting pipe 3 is welded in the hole of the main valve seat 2. The main valve seat 2 cooperates with the slider 4 to close the cavity to change the flow direction of the refrigerant to realize the cooling and heat reversing function of the air conditioner.

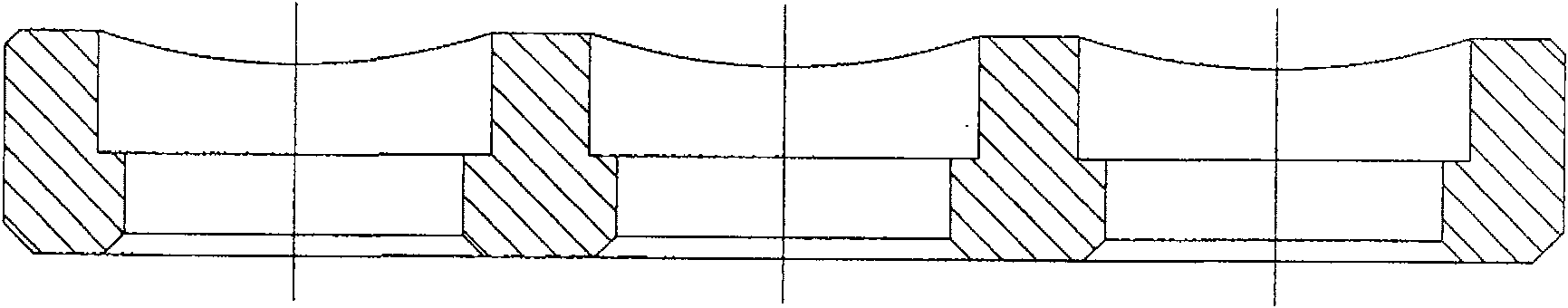

[0032] like Figure 4 As shown, in the prior art, round copper is first processed into special-shaped copper rods, and then plane chamfering, stamping, punching, chamfering and deburring are carried out after blanking. During the process of drilling, turning and other processes, a large amount of material waste will be generated, and the material waste is serious. The connection between molecular crystals is not firm, and it is easy to be deformed by heat and pressure.

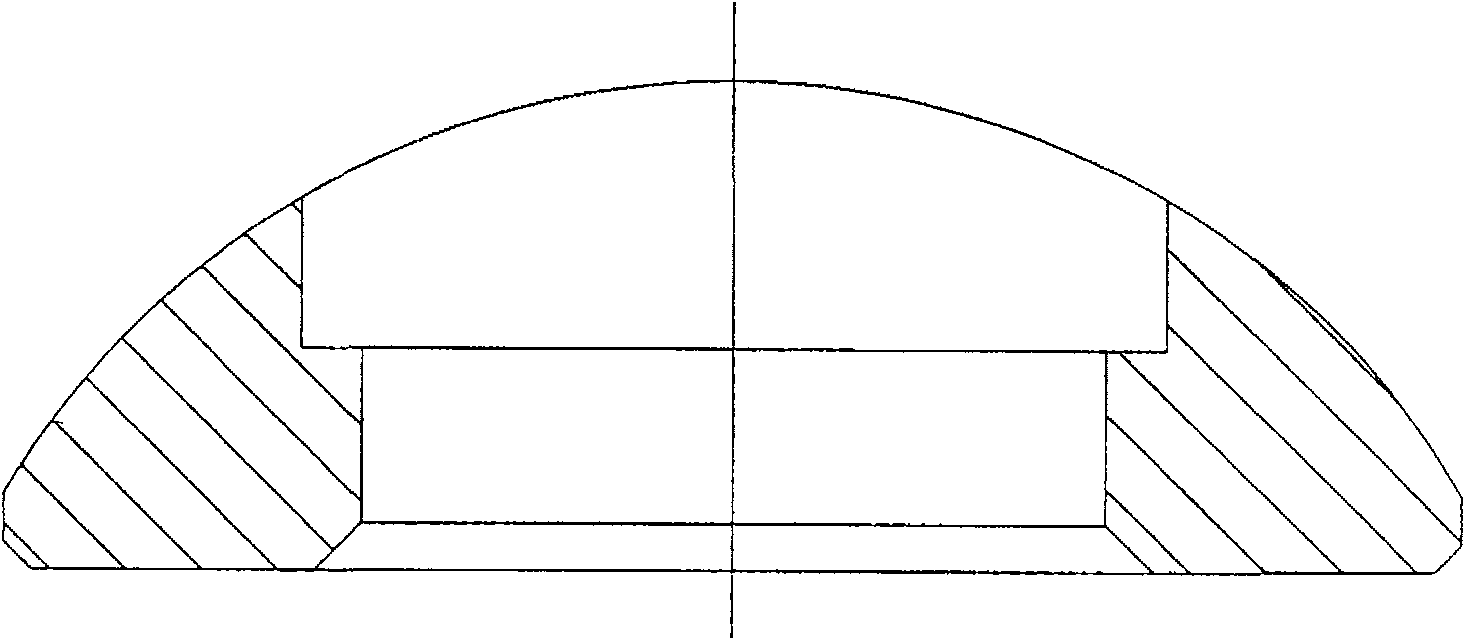

[0033] like Figure 5 As shown, the processing method for the main valve seat of the electromagnetic four-way valve includes the following s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com