Nickel iron blast furnace smelting process with nickel oxide ore as raw material

A blast furnace smelting and nickel oxide technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as environmental pollution, affecting the purity of ferronickel, and increasing the production cost of smelting ferronickel, so as to reduce environmental pollution and solve nickel ore resources Crisis, the effect of reducing smelting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0027] Example 1-5: Ferronickel blast furnace smelting process using nickel oxide ore sinter as raw material

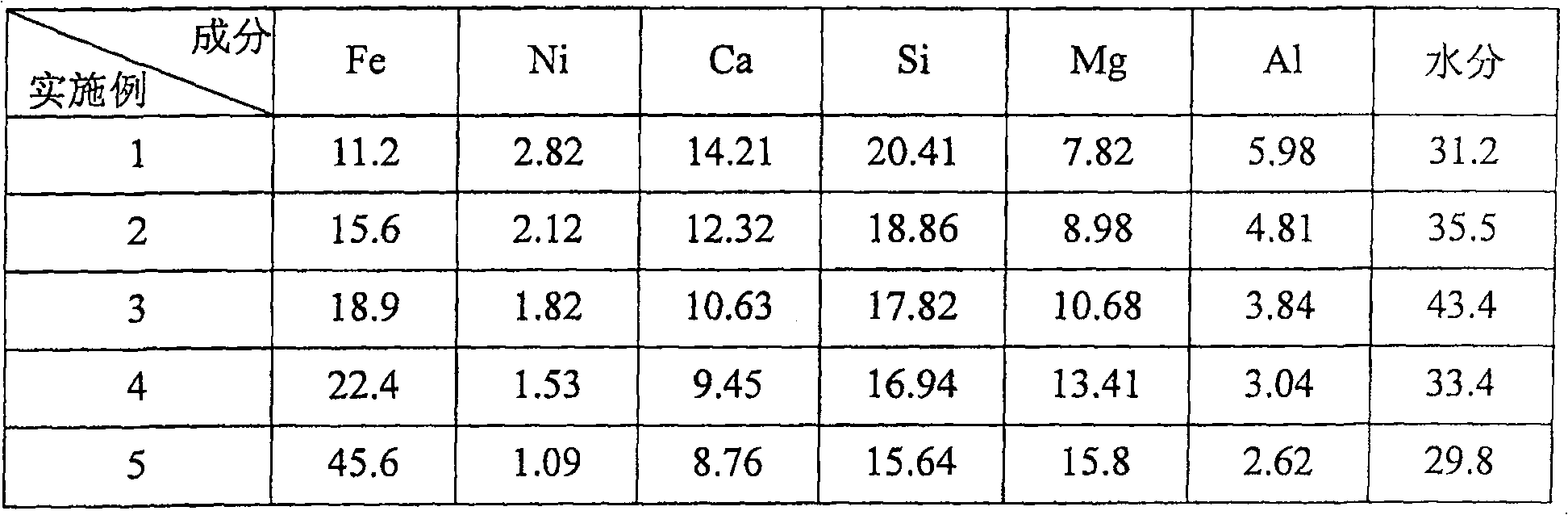

[0028] Raw materials for smelting: the main components and contents of nickel oxide ore are shown in Table 1. The nickel oxide ore used in Examples 1-5 of the present invention is laterite nickel ore from the Philippines or Indonesia.

[0029] Smelting process: Mix and stir nickel oxide ore raw ore powder with quicklime, sieve raw ore powder with a particle size below 15mm, mix ingredients with anthracite / coke powder and quicklime to obtain sintered ore; sinter ore larger than 5mm and coke and Other auxiliary materials are mixed and put into the blast furnace for smelting to obtain ferronickel.

[0030] Table 1: Main components and content (mass percentage, unit: %) of nickel oxide ore

[0031]

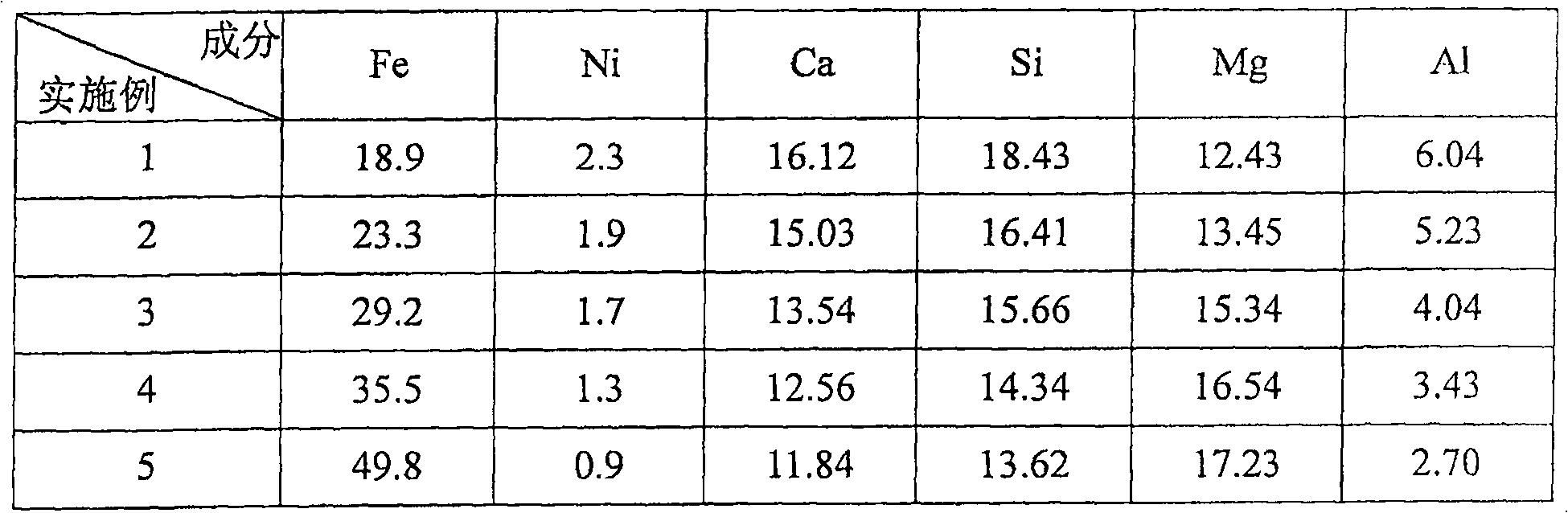

[0032] Table 2: Main components and contents of sintered ore (mass percentage, unit: %)

[0033]

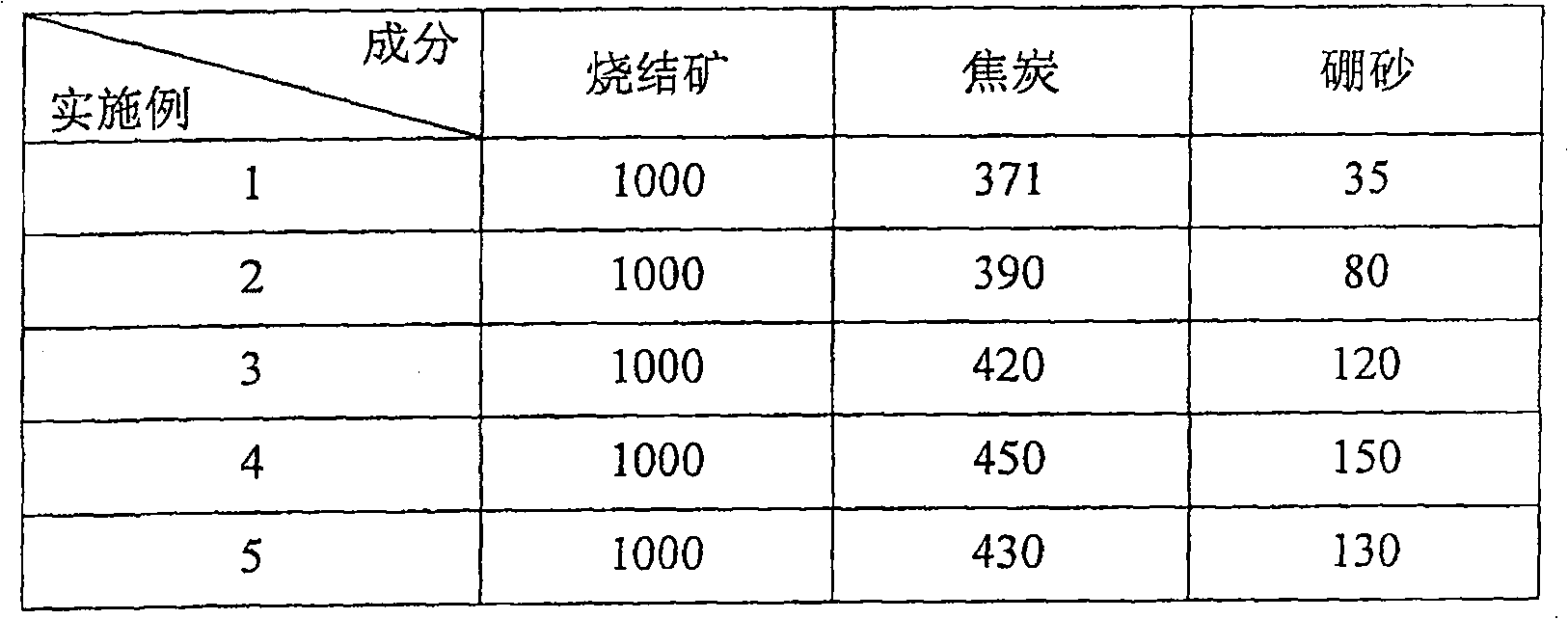

[0034] In Examples 1-5, the addition amounts of the sintered ore, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com