Sintered sliding material, sliding member, connection device and device provided with sliding member

一种滑动材料、滑动构件的技术,应用在发动机元件、机械驱动的挖掘机/疏浚机、基料等方向,能够解决不能够充分防止、缓慢、破坏等问题,达到良好耐焙烧性、耐磨损性优异、跑合性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

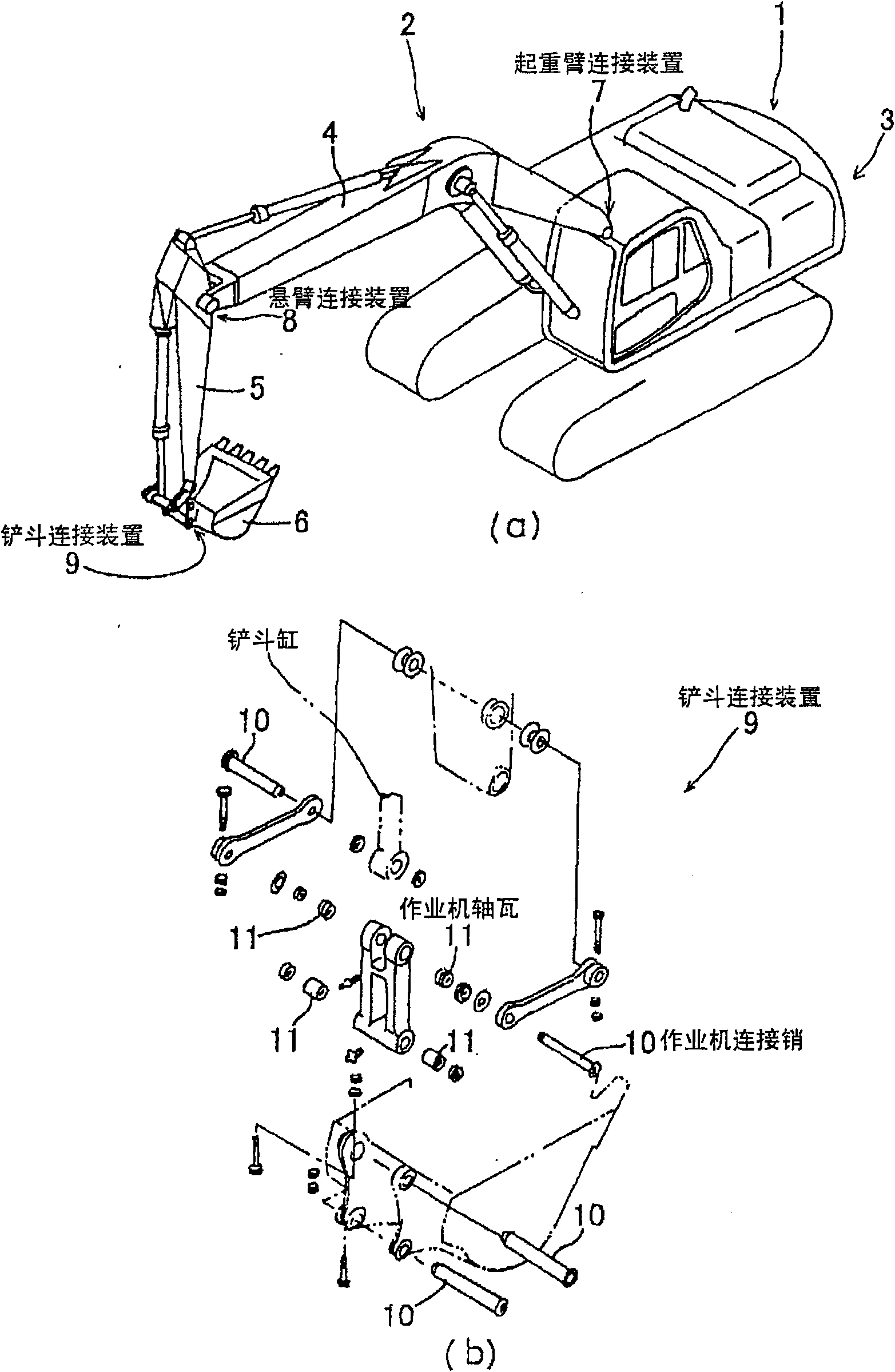

[0169] Next, specific examples of the present invention will be described with reference to the drawings.

[0170] (Manufacturing method and verification of sintered material)

[0171] In this example, Mo(1) powder (average particle size 0.8 μm), Mo(2) powder (average particle size 4.7 μm), NiO (average particle size 0.7 μm), atomized copper powder (Japan atomized , SFR-Cu average particle size 10 μm), Ni powder (average particle size 1.2 μm), and TiH and Sn powders below #350 mesh were made into mixed powders as shown in Table 1, and 3% by mass was added to these mixed powders of paraffin, by adding 2ton / cm 2 pressure to form a cylindrical shape with an inner diameter of 46mm and a height of 50mm. Then, after sintering the obtained compacts at 950-1250°C for 1 hr, 2 Cooling under gas.

[0172] 【Table 1】

[0173] Combination structure of test material for Mo-based sliding material (% by weight)

[0174] 0.8μm 4.7μm CE25 1.2μm#350 or less

[0175]

[0176] Here, No.A1...

Embodiment 2

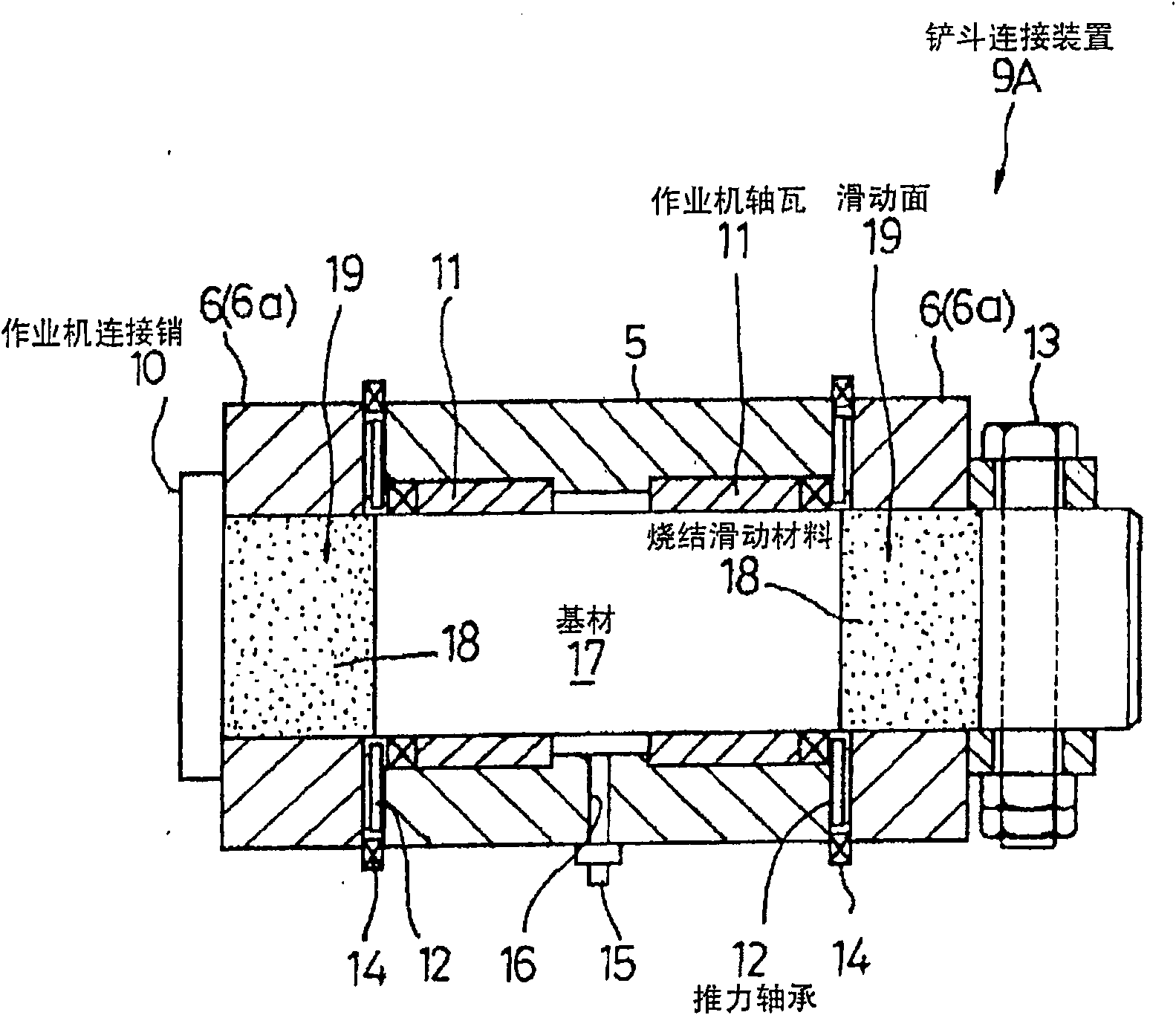

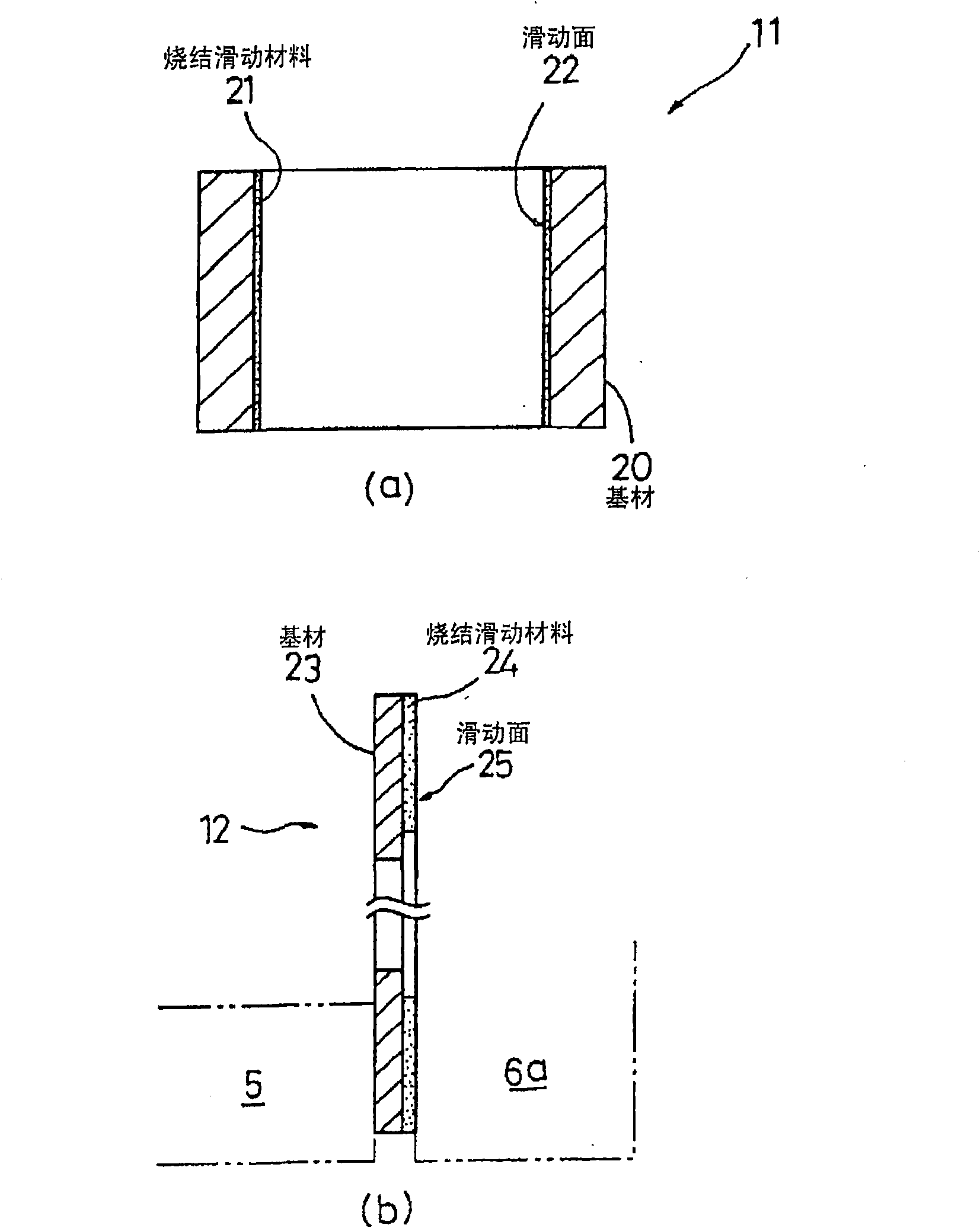

[0196] (Bearing test)

[0197] In this embodiment, to Figure 15 A bearing test between the test bearing pad and the test bearing shaft was carried out under the condition that the sintered sliding material of the present invention was fixed in any of the test bearing pad and the test bearing shaft having the shapes shown. The roughness of the sliding surface, excluding the sintered holes, is all lathe-processed holes of about 2 to 5 μm, and the test bearing shaft used to fix the sliding fitting member of the test bearing pad of the sintered sliding material of the present invention is adjusted as follows , The surface layer of S45C carbon steel is subjected to high-frequency quenching and tempering (160 ° C), the surface hardness is HRC56, and the surface roughness is 1-3 μm or less through grinding. In addition, in the test bearing pad of the test bearing shaft to which the sintered sliding material of the present invention is fixed, 0.7% by mass of graphite powder (average...

Embodiment 3

[0292] Next, specific examples of the present invention will be described with reference to the drawings.

[0293] (Manufacturing method and verification of sintered sliding material)

[0294] In this example, Mo (1) powder (average particle diameter: 0.8 μm) and Mo (2) (average particle diameter: 4.7 μm) were blended with 3% by mass of paraffin wax, and the powder was pressed at 2 ton / cm 2 pressure to form a cylindrical shape with an inner diameter of 46mm and a height of 50mm. Then, after sintering the obtained compacts at 950-1250° C. for 1 hr, they were sintered with N 2 The gas is cooled.

[0295] Here, the molded body mainly composed of Mo(1) powder (molded body density: 4.65gr / cm 3 ), has shown significant shrinkage at 950°C, and its sinterability has been found. At 1100°C, 1150°C, and 1200°C, respectively, its sinterability is basically saturated, showing a significant shrinkage rate of 14.6%. A relative density of 74% (porosity of 41%) can be achieved to increase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com