Acrylic resin used for PVDF fluorocarbon coating and synthetic method of acrylic resin

An acrylic resin and fluorocarbon coating technology, applied in the coating and other directions, can solve the problems of insufficient temperature resistance, affecting the appearance effect, and the paint is easy to turn yellow, and achieves improved performance, excellent appearance effect, and excellent resistance. baking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

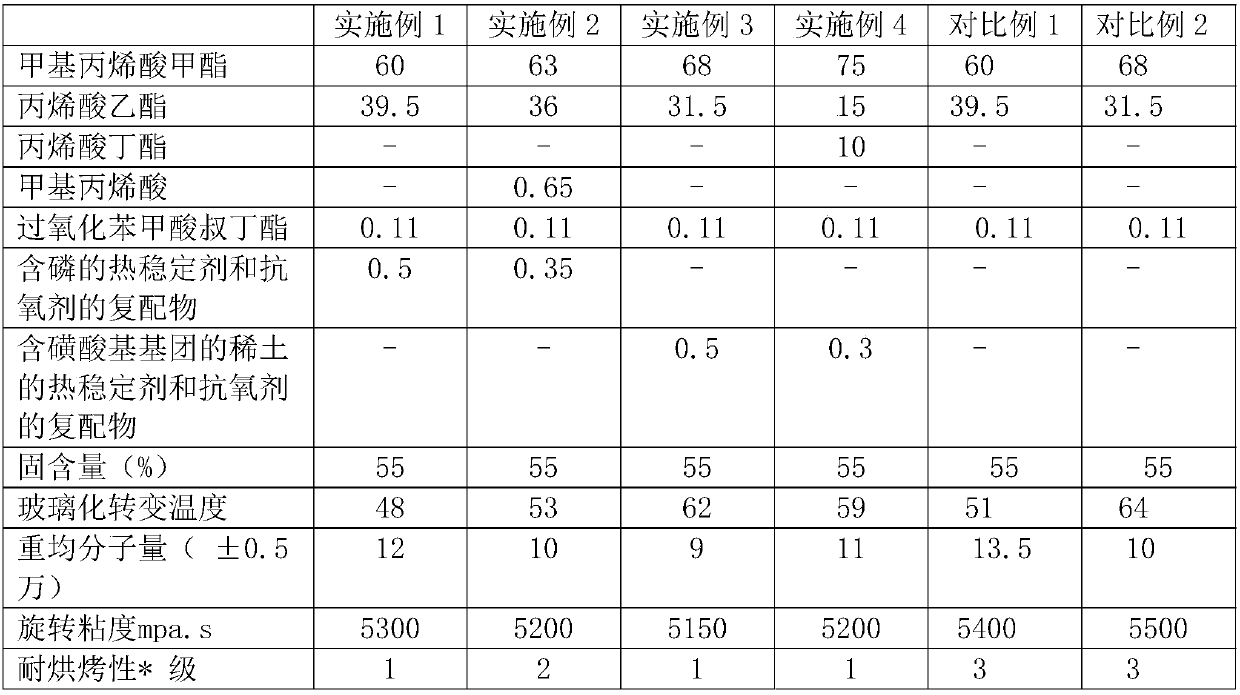

Embodiment 1

[0025] An acrylic resin for PVDF fluorocarbon coatings, including monomers, the monomers include at least one methacrylate monomer and at least one acrylate monomer, and also include a functional baking-resistant anti-yellowing additive, The functional baking and anti-yellowing auxiliary agent is selected from a compound of a phosphorus-containing heat stabilizer and an antioxidant and / or a compound of a rare earth heat stabilizer and an antioxidant containing a sulfonic acid group thing.

[0026] The monomer is synthesized by a copolymerization reaction, and the copolymerization reaction is a solution polymerization reaction.

[0027] Calculated in terms of mass percentages: the methacrylate monomer accounts for 55-75%, the acrylate monomer accounts for 20-50%, and the functional baking-resistant anti-yellowing additive accounts for 1-3%.

[0028] The methacrylate monomer is selected from at least one of methyl methacrylate, ethyl methacrylate, and n-butyl methacrylate.

[...

Embodiment 2

[0043] Prepare the acrylic resin according to the method of Example 1, the monomers also include functional compound monomers, and the functional compound monomers can carry out copolymerization reaction with the methacrylate monomer and acrylate monomer; The functional compound monomer is an unsaturated carboxylic acid monomer, and the proportion of the functional compound monomer in the monomer is no more than 2% in terms of mass percentage.

[0044] Its specific formula parameters are as follows:

[0045] 63 parts by mass of methyl methacrylate, 36 parts by mass of ethyl acrylate, the functional compound is preferably methacrylic acid, its consumption is 0.65 parts by mass, and 0.35 parts of phosphorus-containing functional baking-resistant and anti-yellowing additives; The initiator is tert-butyl peroxybenzoate in an amount of 0.11 parts by mass; xylene is used as a polymerization solvent for the copolymerization reaction, so that the solid content of the reaction system i...

Embodiment 3

[0047] Prepare described acrylic resin according to the method of embodiment 1, and its specific formulation parameters are as follows:

[0048] 68 parts by mass of methyl methacrylate, 31.5 parts by mass of ethyl acrylate, 0.5 parts of functional baking-resistant and anti-yellowing additives containing rare earth sulfonic acid groups; the initiator is tert-butyl peroxybenzoate, and the dosage is 0.11 parts by mass Parts; use xylene as the polymerization solvent to carry out the copolymerization reaction, so that the solid content of the reaction system is 55%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com