Controller for hydraulic construction machine

A technology for hydraulic construction machinery and control devices, applied in engine control, fluid pressure actuation device, electrical control, etc., can solve the problems of discontinuous engine rotation fluctuations, undesired mode switching by the operator, and incongruity, etc. The effect of reducing performance degradation, improving fuel consumption, and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

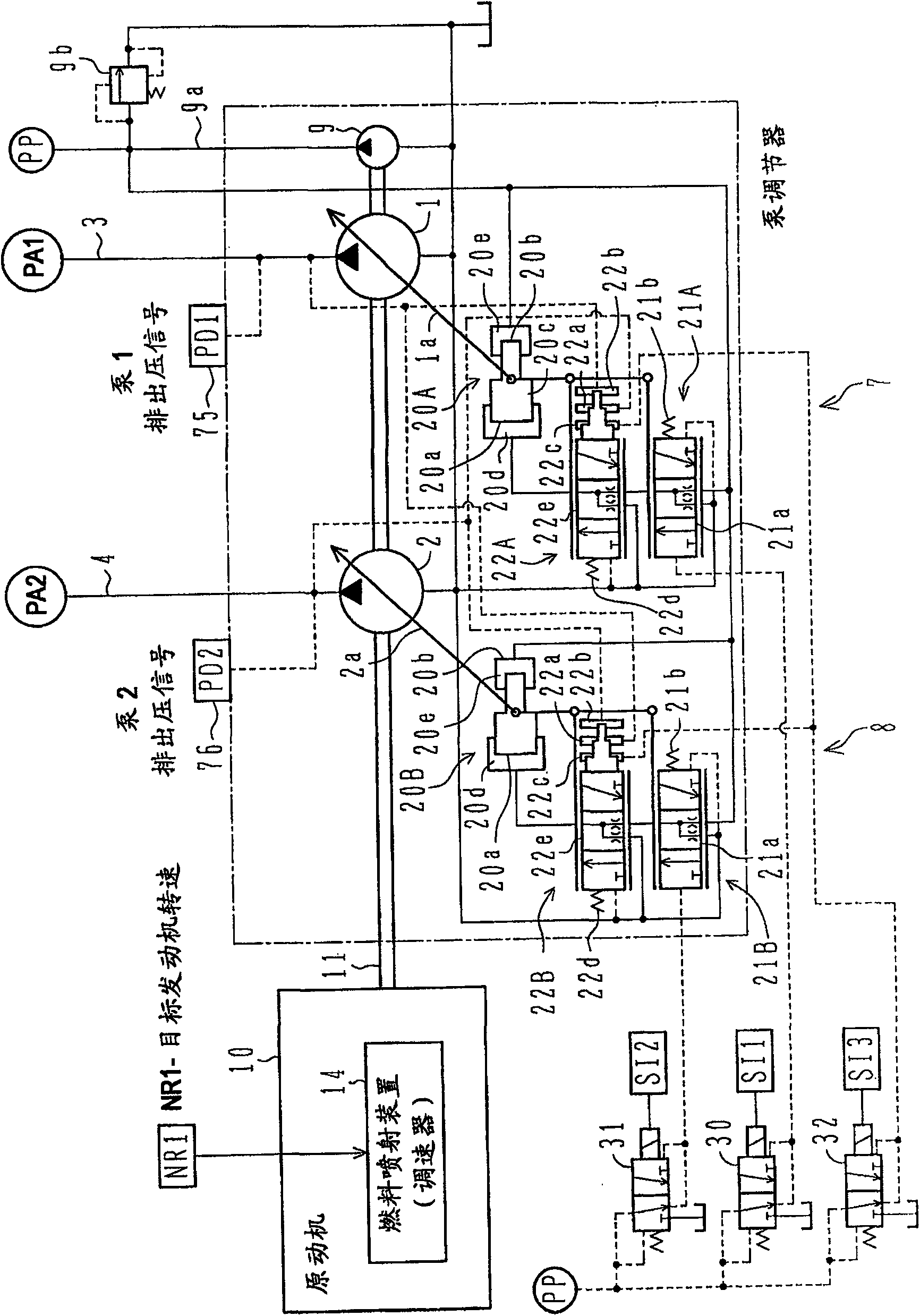

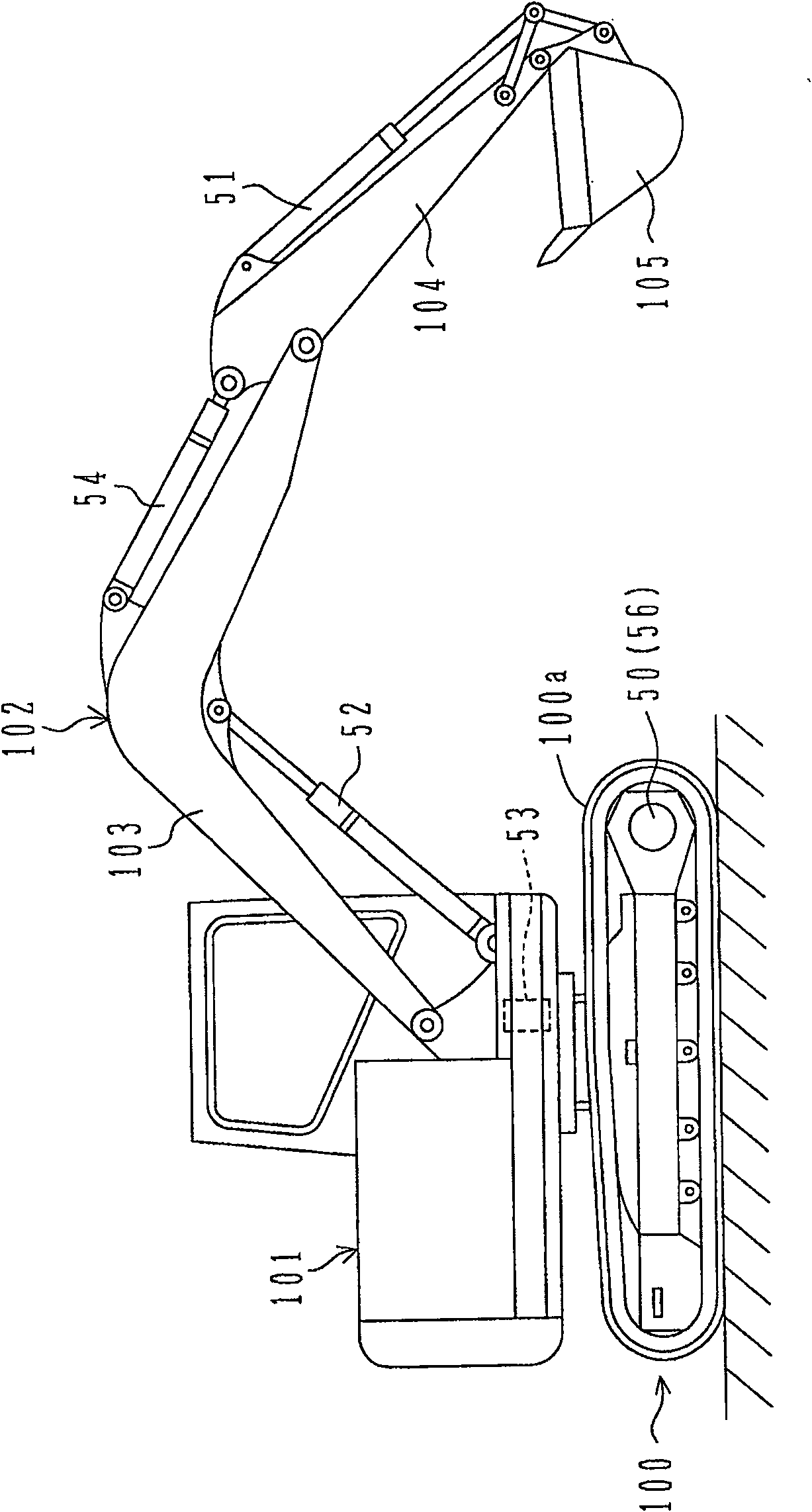

[0083] Embodiments of the present invention will be described below using the drawings. The following embodiments are cases in which the present invention is applied to a prime mover of a hydraulic shovel and a control device for a hydraulic pump.

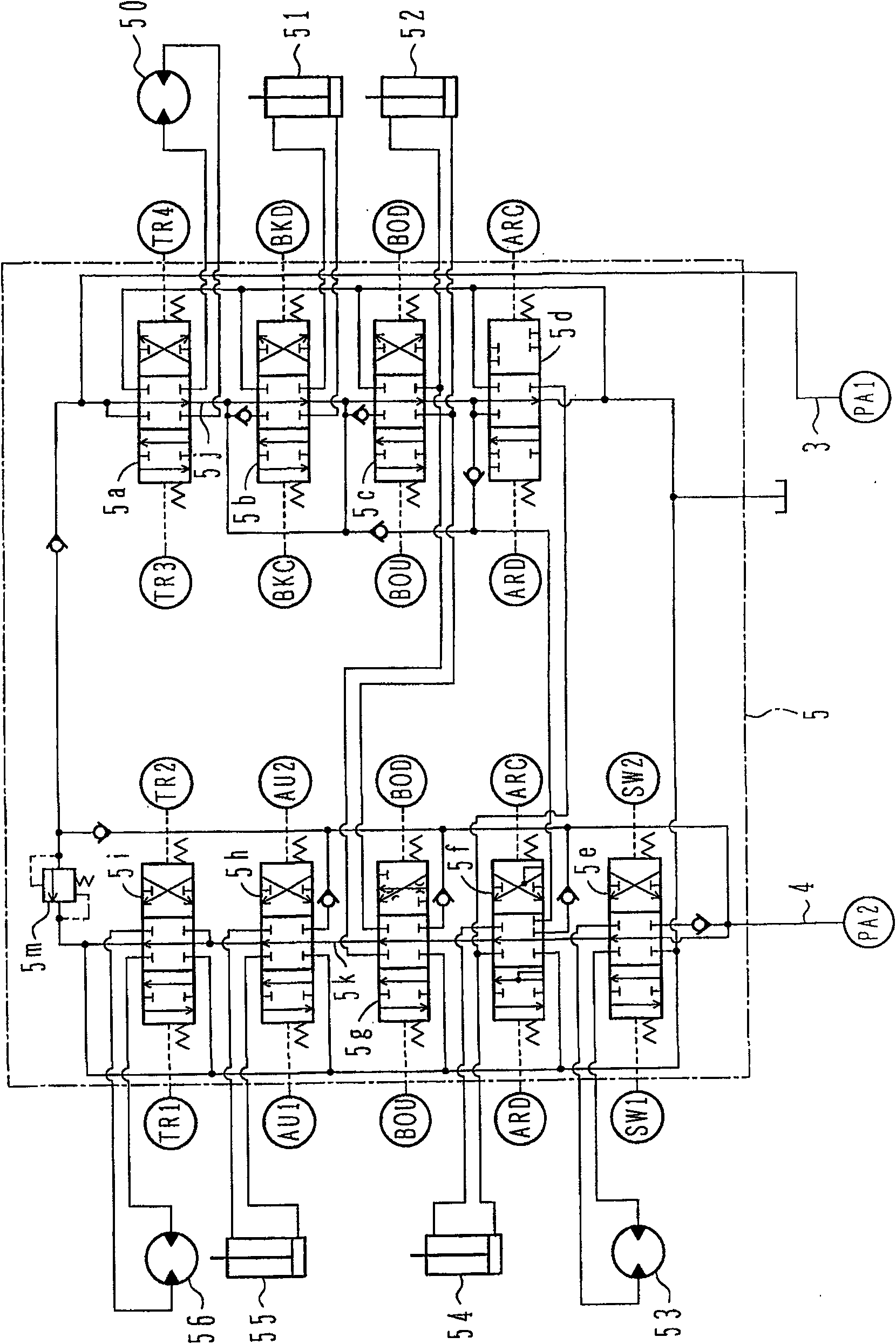

[0084] exist figure 1 Among them, 1 and 2 are, for example, swash plate type variable capacity hydraulic pumps, and the discharge paths 3 and 4 of the hydraulic pumps 1 and 2 are connected to figure 2 The shown valve device 5 sends hydraulic oil to a plurality of actuators 50 to 56 via the valve device 5 and drives these actuators.

[0085] 9 is a pilot pump of fixed capacity type, and the pilot relief valve 9b which maintains the discharge pressure of the pilot pump 9 to a constant pressure is connected to the discharge path 9a of the pilot pump 9.

[0086] The hydraulic pumps 1 and 2 and the pilot pump 9 are connected to the output shaft 11 of the prime mover 10 and are rotationally driven by the prime mover 10 .

[0087] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com