A method for preparing poly(ether-ether-ketone) rod bar

A technology of polyether ether ketone and polyetherether ketone resin, which is applied in the field of plastic products and profiles, can solve the problems of high mold production costs, etc., and achieve the effects of high dimensional stability, uniform cross-section, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

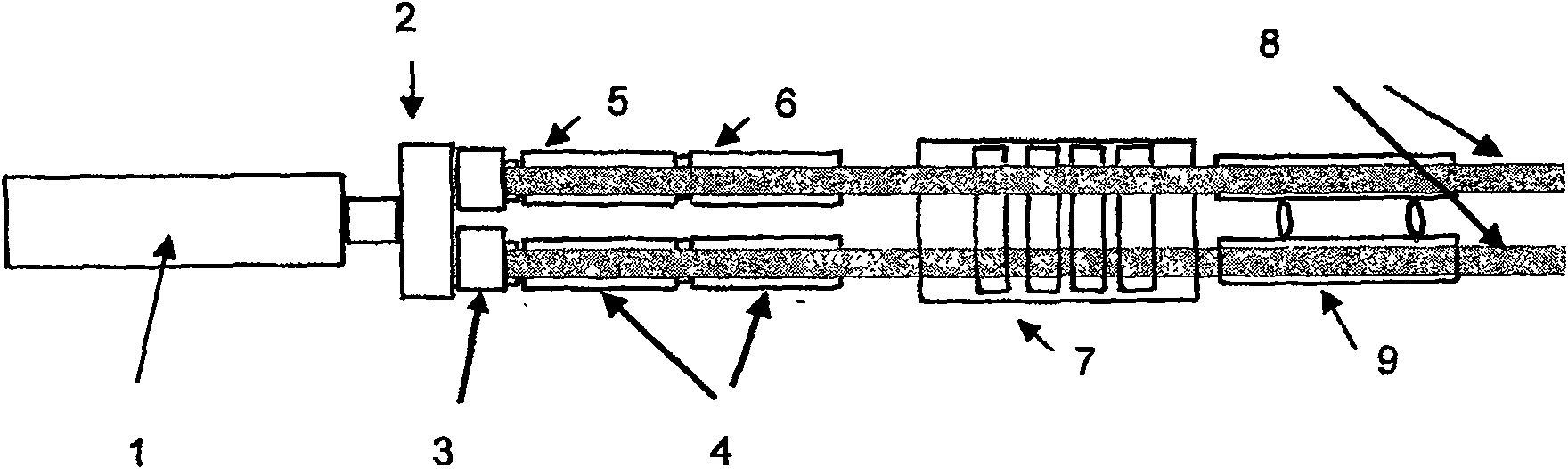

[0030] Such as figure 1 In the extrusion production line shown, the polyether ether ketone resin of natural color is melted at 400°C in a single-screw extruder, and the melt is extruded into the mouth die through the head of the extruder, and then directly enters the two-stage cooling and sizing The length of each sizing sleeve is 300mm. As mentioned above, the heat transfer oil is high temperature resistant dibenzyltoluene. The resin density is evenly filled with the die and the sizing sleeve in turn, and in the process of moving forward at a constant speed (corresponding to the rotation speed of the extruder screw, the extrusion speed of the rod is 3-6mm / min), at the first Cooling and sizing at 200°C in the first sizing sleeve, and then cooling and sizing at 120°C in the second sizing sleeve to obtain polyether ether ketone rods with a diameter of D51±1mm.

[0031] After the polyetheretherketone rod is crystallized by gradient cooling and sizing, it is introduced by the tra...

Embodiment 2

[0039] As in Example 1, only the natural color PEEK resin was replaced with black PEEK resin (adding 0.2% by weight carbon black for coloring), and the same method and process were used to obtain black PEEK rods.

[0040] With the method of Example 1, the roundness of the bar prepared in this embodiment is studied, for this reason, the diameter of the bar is measured at 5 different points on the cross section of the bar, and the results are as follows:

[0041] Table 3: Diameter data of polyetheretherketone rods prepared in Example 2:

[0042]

[0043] The data in the table shows that the roundness of the prepared black rod is better and the diameter is more uniform.

Embodiment 3

[0045] As in Example 1, only the natural color polyetheretherketone resin was replaced with green polyether ether ketone resin (adding 0.2% by weight of chrome green for coloring), and the same method and process were used to obtain green polyetheretherketone rods.

[0046] With the method of Example 1, the roundness of the bar prepared in this embodiment is studied, for this reason, the diameter of the bar is measured at 5 different points on the cross section of the bar, and the results are as follows:

[0047] Table 4: Diameter data of polyetheretherketone rods prepared in Example 3:

[0048]

[0049] The data in the table shows that the roundness of the prepared green rod is better and the diameter is more uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com