Spinning device and method for spinning synthetic thread

A spinning device and filament technology, applied in the field of spinning synthetic filaments, can solve problems such as hindering the forward movement of monofilaments, and achieve the effects of high spinning reliability, uniform cross-section of monofilaments, and no loose hair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

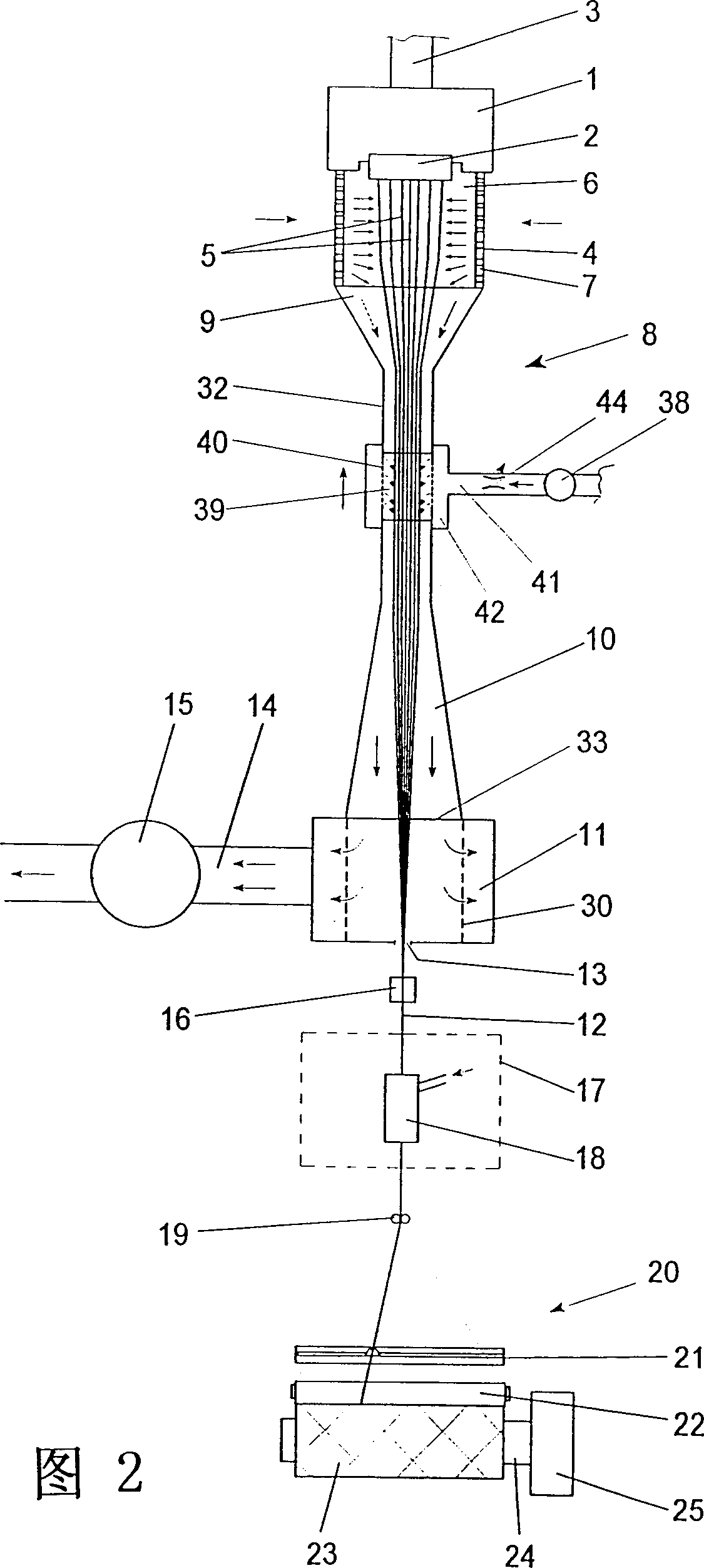

[0030] FIG. 1 shows a first embodiment of a spinning device according to the invention for spinning synthetic filaments.

[0031]Filament 12 is spun from a thermoplastic material. For this purpose the thermoplastic material is melted in an extruder or pump. The melt is fed to the spinning head 1 via the melt line 3 by means of a spinning pump. A spinneret 2 is mounted on the bottom surface of the spinneret 1 . The melt emerges from the spinneret 2 in the form of filament strands 5 . The monofilaments 5 pass through a spinning shaft 6 as a monofilament bundle, which is formed by a gas inlet tube 4 . To this end, the gas cylinder 4 is arranged immediately below the spinning head 1 and surrounds the monofilaments 5 . A first cooling pipe 8 is connected to the free end of the air inlet tube 4 along the running direction of the filament. The cooling tube has an inlet 9 on the side where the filaments enter. Preferably, the inlet 9 made into a funnel shape is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com