Nonaqueous electrolyte secondary battery

一种非水电解质、二次电池的技术,应用在非水电解质蓄电池、二次电池、锂蓄电池等方向,能够解决短路部分易扩大等问题,达到防止绕线位移、提高输出特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

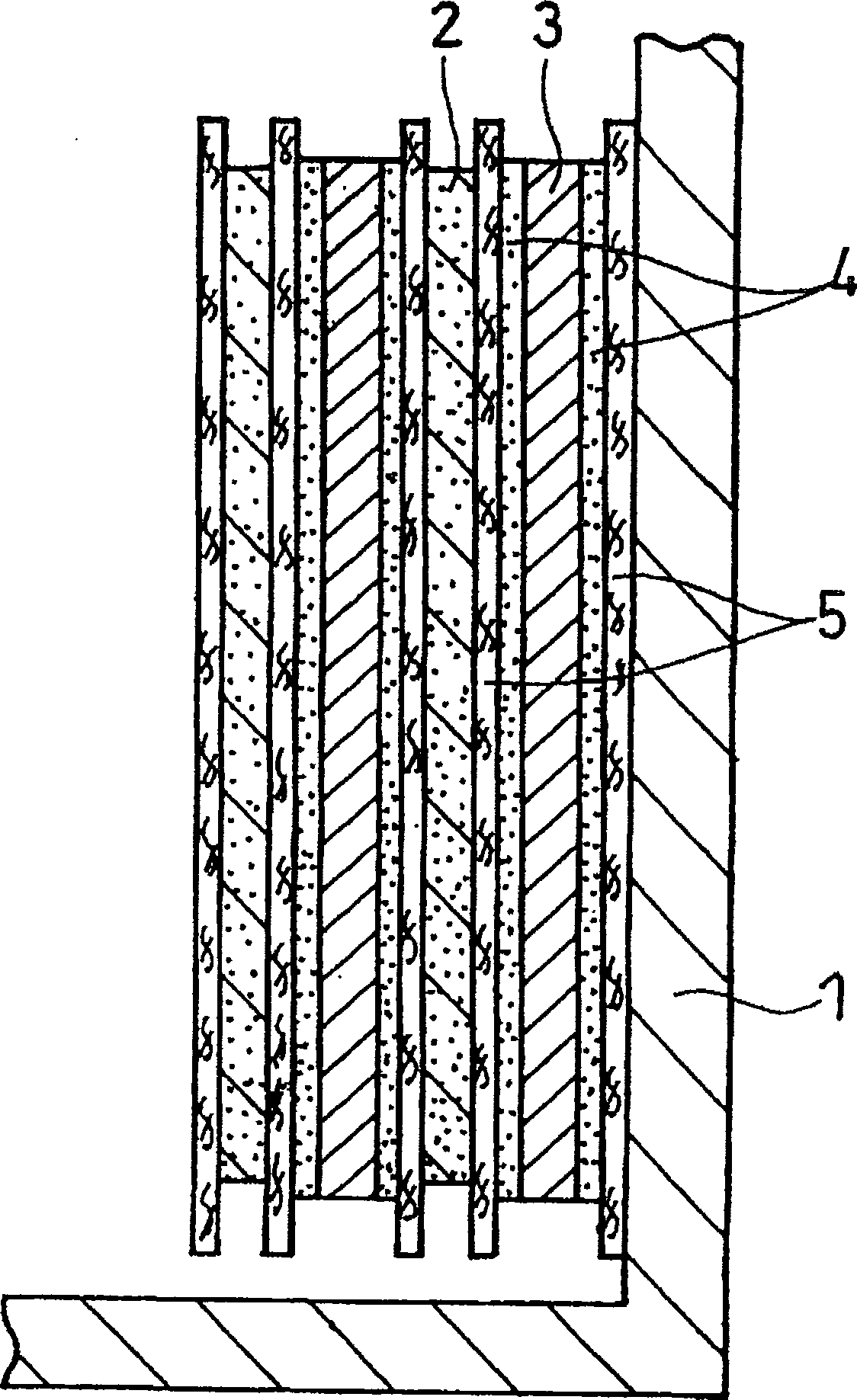

Image

Examples

Embodiment 1

[0092] (Battery 1)

[0093] (production of positive electrode)

[0094] 30 kg of LiNi as the cathode active material was stirred by using a double-arm kneader 0.71 co 0.2 Al 0.05 mn 0.02 Mg 0.02 o 2 , 10 kg of polyvinylidene fluoride (PVDF) in N-methyl-2-pyrrolidone (NMP) (#1320, purchased from Kureha Chemical Industry Co., Ltd. (solid content: 12 wt %)) solution, 900 g of acetylene as a conductive agent black, and an appropriate amount of NMP to prepare positive electrode active material mixed slurry. The slurry thus obtained was coated on both surfaces of an aluminum foil (thickness: 15 μm) as a current collector, which was then dried and rolled until its total thickness reached 108 μm, thereby producing a positive electrode plate. Subsequently, the positive electrode plate was cut such that the size of the positive electrode active material on each surface of the current collector was 56 mm in width and 600 mm in length, thereby manufacturing a positive electrode. T...

Embodiment 2

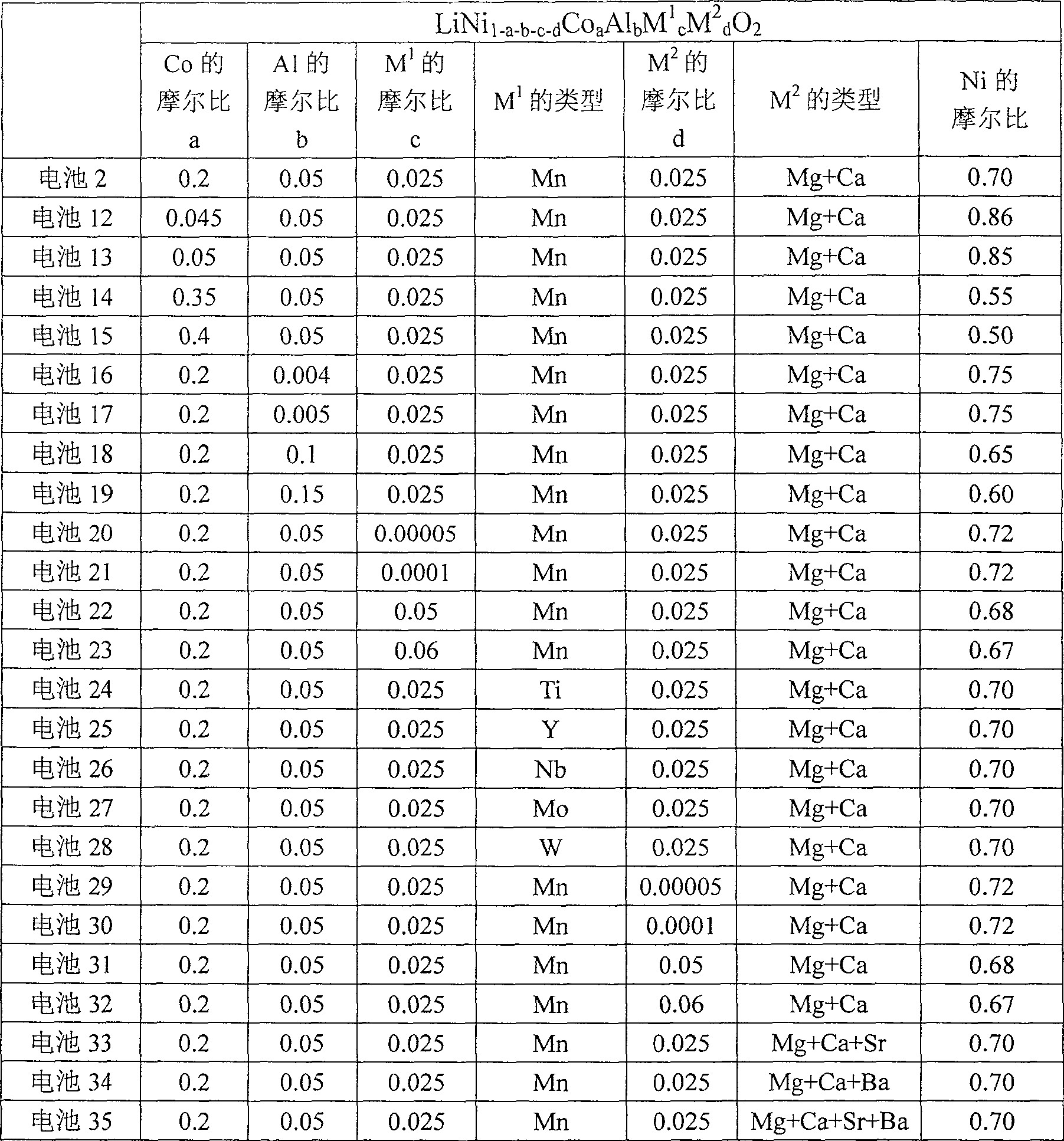

[0141] (Battery 12~35)

[0142] Batteries 12-35 are manufactured in the same manner as battery 2, except that the general formula (1) is used: LiNi 1-a-b-c-d co a Al b m 1 c m 2 d o 2 positive active material shown, and M 1 and M 2 Use the elements shown in Table 3, and Ni, Co, Al, M 1 and M 2 The change of the molar ratio is shown in Table 3. Here, M 2 Contains 2 to 4 elements. m 2The molar ratios of each element contained in are the same. The molar ratio d is the element M in the oxide shown in general formula (1) 2 total molar ratio.

[0143] Table 3 (to be continued)

[0144]

[0145] Table 3 (continued)

[0146]

Ah per unit battery capacity

The area of the positive electrode active material layer

(cm 2 ) negative active material

layer area

(cm 2 ) porous heat-resistant layer

area

(cm 2 ) non-aqueous electrolyte

amount

(ml) Ratio B / A

(ml / m 2 ) battery 2 395 371 742 7.4 100 ...

Embodiment 3

[0162] (Battery 36~64)

[0163] Batteries 36-64 are manufactured in the same manner as battery 2, except that the general formula (2): LiNi a co b mn c m 3 d o 2 Positive electrode active materials shown, along with the molar ratio a of nickel, b of cobalt, c of manganese, and the element M 3 The type and molar ratio d of the changes are shown in Table 5.

[0164] Table 5 (to be continued)

[0165]

[0166] Table 5 (continued)

[0167]

Ah per unit battery capacity

The area of the positive electrode active material layer

(cm 2 ) Negative active material

The area of the material layer

(cm 2 ) Porous heat-resistant layer

the area of

(cm 2 ) non-aqueous electrolysis

quality quantity

(ml) Ratio B / A

(ml / m 2 ) battery 36 395 371 742 7.4 100 battery 37 395 371 742 7.4 100 battery 38 395 371 742 7.4 100 battery 39 395 371 742 7.4 100 battery 40 395 371 742 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com