Reduction-reducing crack-resisting concrete superplasticizer of graft copolymer and method for preparing the same

A technology of graft copolymer and superplasticizer, which is applied in the field of concrete structure, concrete engineering and concrete admixture, and can solve the problems of insufficient water reducing rate, poor cement dispersion performance and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

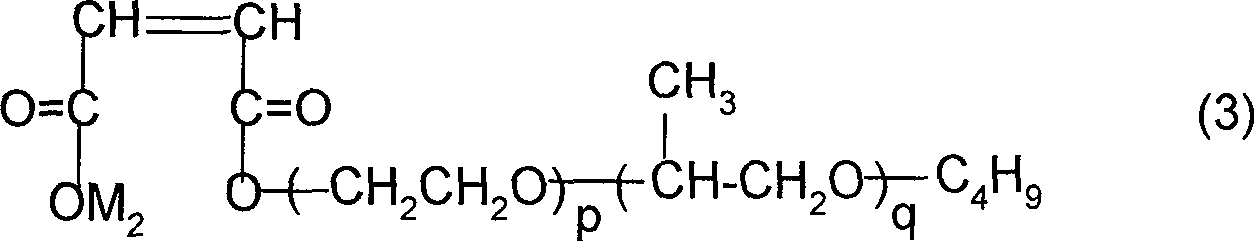

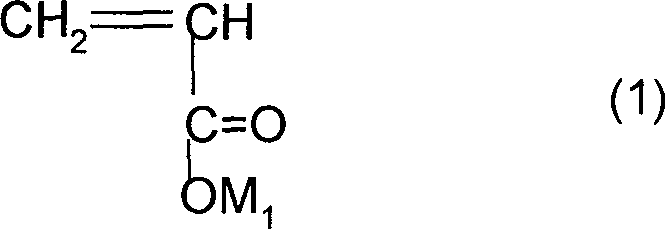

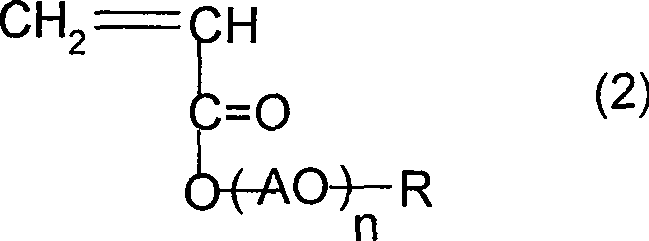

[0080] In the 2000ml glass reactor equipped with thermometer, stirrer, dropping funnel, nitrogen inlet tube and reflux condenser, add 600ml ethyl acetate, purging reaction vessel with nitrogen while stirring, and be warming up to 75 ℃. Then 1.0 mol of monomer A-1, 0.35 mol of monomer B-1 (n=9) and 0.2 mol of monomer C-1 (p=2, q=2, M 2 =H), 0.15mol monomer D-1 (m=12) and 0.05mol styrene, 0.027mol azobisisobutyronitrile (AIBN), 8.5g mercaptopropionic acid, also add 200ml ethyl acetate simultaneously, and stir Prepare a uniform monomer aqueous solution, add it dropwise to the reactor, the dropping time is 3h, keep warm for 4h after the dropwise addition, and then heat up to recover the ethyl acetate organic solution, which can be used multiple times, add water to dilute and cool, and add alkali Neutralize to pH 7.5 to obtain a brown transparent liquid with a solid content of 30.7% and a molecular weight of 42,000.

Embodiment 2

[0082] In the 2000ml glass reactor equipped with thermometer, stirrer, dropping funnel, nitrogen inlet tube and reflux condenser, add 600ml ethyl acetate, purging reaction vessel with nitrogen while stirring, and be warming up to 75 ℃. Then 1.0 mol of monomer A-1, 0.20 mol of monomer B-2 (n=17) and 0.15 mol of monomer C-3 (p=4, q=0, M 2 =H) and 0.15mol monomer D-1 (m=12), 0.040mol azobisisobutyronitrile (AIBN), 10.2g mercaptopropionic acid, also add 200ml ethyl acetate simultaneously, and stir to make uniform mono Aqueous aqueous solution, drop it into the reactor, dropwise time is 5h, heat preservation reaction for 3h after dropwise addition, then heat up to recover ethyl acetate organic solution, can be used multiple times, add water to dilute and cool, and add alkali to neutralize to pH value 7.5, the solid content is 30.2% brown transparent liquid, the molecular weight is 29,000.

Embodiment 3

[0084] In the 2000ml glass reactor equipped with thermometer, stirrer, dropping funnel, nitrogen inlet tube and reflux condenser, add 800ml ethyl acetate, purging reaction vessel with nitrogen while stirring, and be warming up to 75 ℃. Then 1.0 mol of monomer A-1, 0.45 mol of monomer B-3 (n=5) and 0.25 mol of monomer C-2 (p=0, q=2, M 2 =H) and 0.20mol of monomer D-2 (m=6), and 0.05mol of styrene, 0.05mol of azobisisobutyronitrile (AIBN), 3.0g of mercaptopropionic acid, while also adding 400ml of ethyl acetate, and Stir to make a homogeneous monomer aqueous solution, add it dropwise to the reactor, the dropwise addition time is 4h, keep warm for 4h after the dropwise addition, then heat up to recover the ethyl acetate organic solution, which can be used multiple times, add water to cool, and add alkali Neutralized to pH 7.5, solid content 30.2% brown transparent liquid, molecular weight 35,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com