Manufacturing method for electronic device

A technology for electronic devices and manufacturing methods, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as disconnection reliability, and achieve the effect of eliminating equipment investment and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0065] (electronic device)

[0066] Next, the present invention will be described in detail.

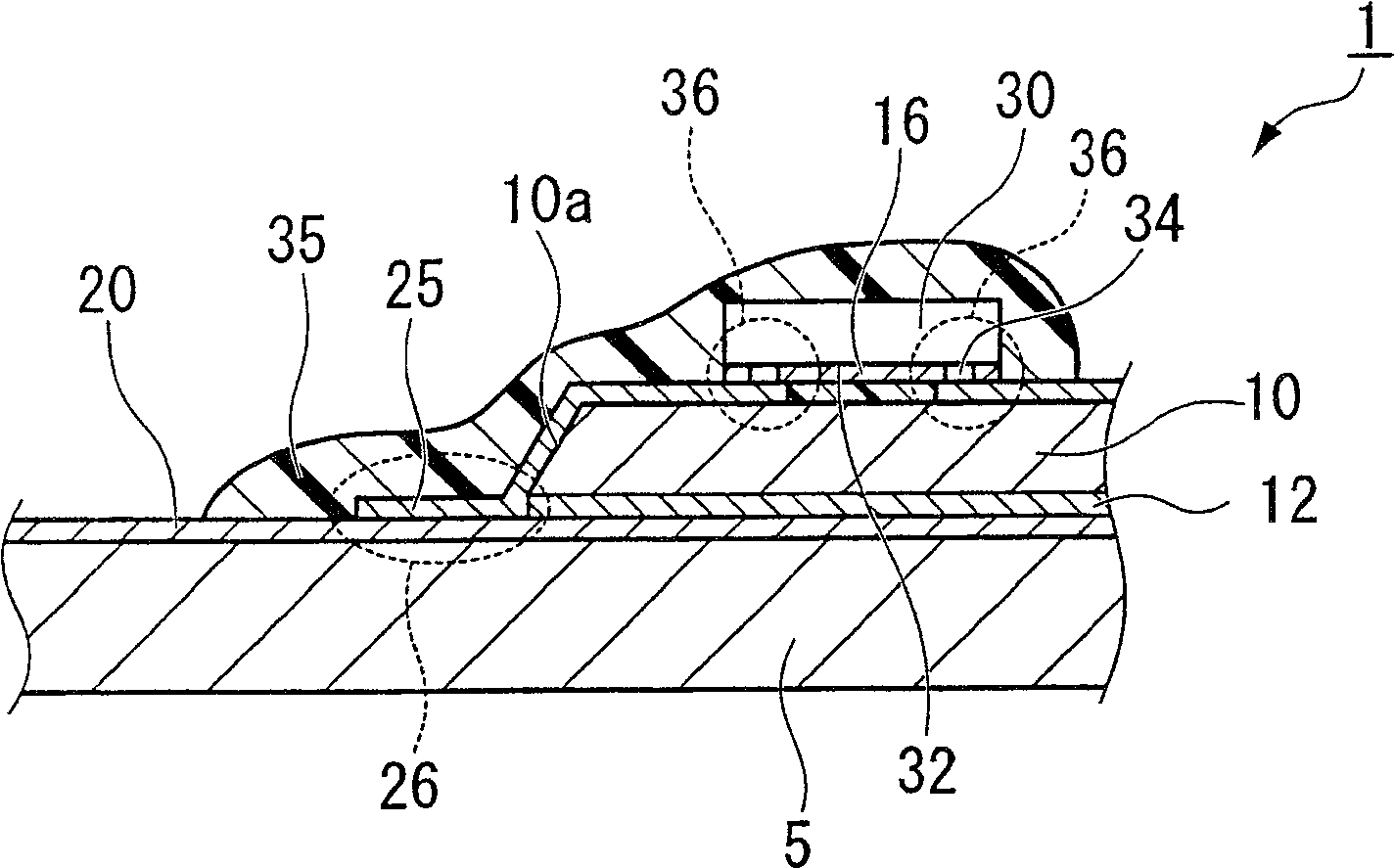

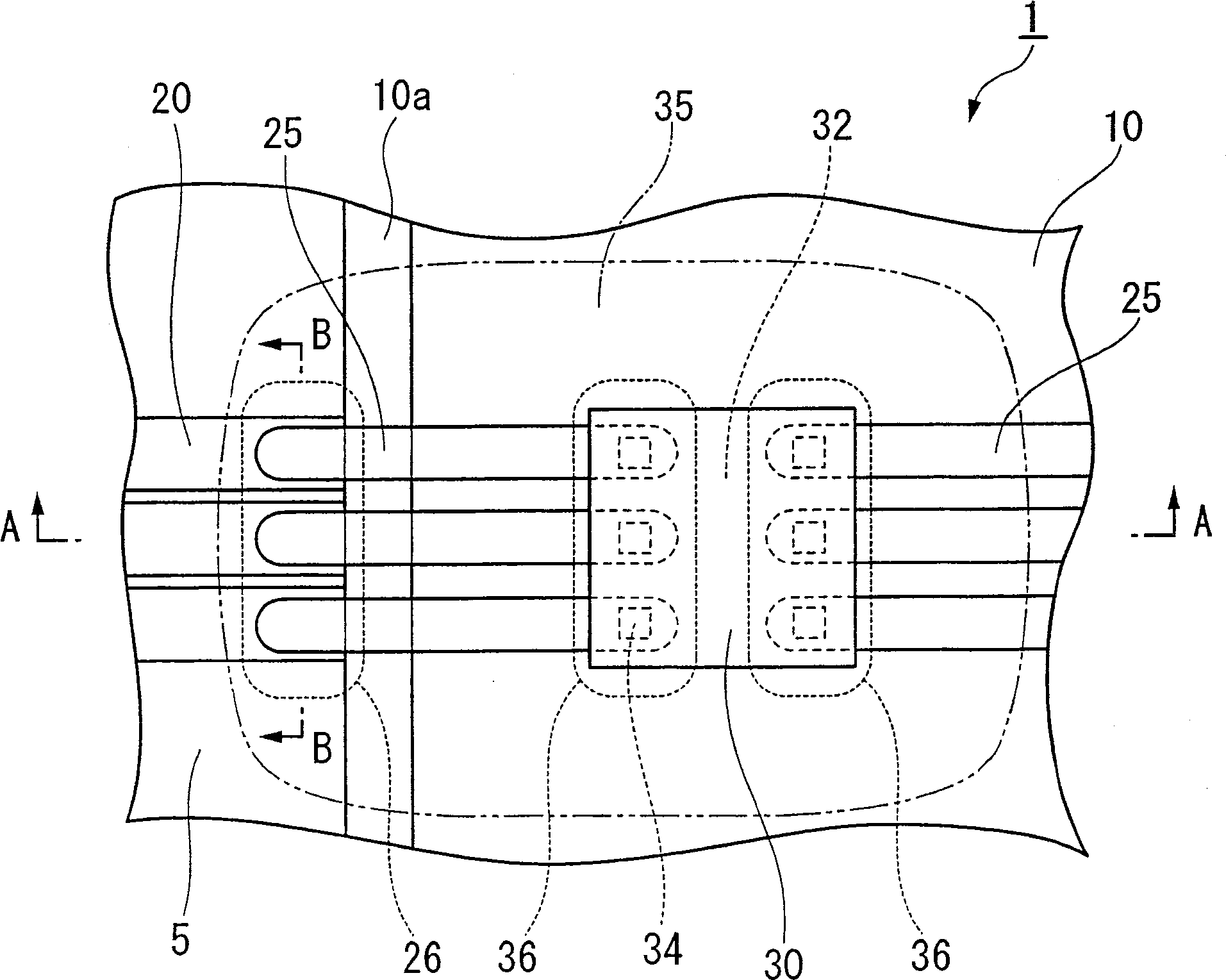

[0067] figure 1 It is a figure which shows and explains the electronic device manufactured using the manufacturing method of the electronic device of this invention, and is figure 2 The side sectional view of A—A line looking down. figure 1 Among them, symbol 1 is the electronic device of the present invention. figure 2 It is a plan view showing a part of the electronic device 1 (resin 35 described later) seen through from a vertical direction, and is a diagram for explaining the electronic device 1 of the present invention.

[0068] Such as figure 1 As shown, the electronic device 1 includes, for example, a substrate 5 made of Si and a pedestal 10 formed on the substrate. The above-mentioned pedestal 10 is, for example, a plate-shaped substrate made of materials such as Si and ceramics. In addition, the above-mentioned pedestal 10 may be an organic substrate, an electronic c...

no. 2 approach

[0105] An example of a preferred embodiment of the electronic device of the present invention will be described below.

[0106] The first embodiment described above is different in that after the seed layer 13 is formed on the entire surface of the substrate 5 and the pedestal 10, plating is performed on the region (opening 15b) partitioned by the photoresist 15. processing, the second wiring 25 is formed. In contrast, in this embodiment, a silane coupling process is performed on a substrate to form a silane coupling film, a seed layer is formed on the silane coupling film, and a plating process is performed to form a second wiring. In addition, the basic configuration of other pattern forming methods is the same as that of the above-mentioned first embodiment, and the same symbols are assigned to common components, and detailed description thereof will be omitted.

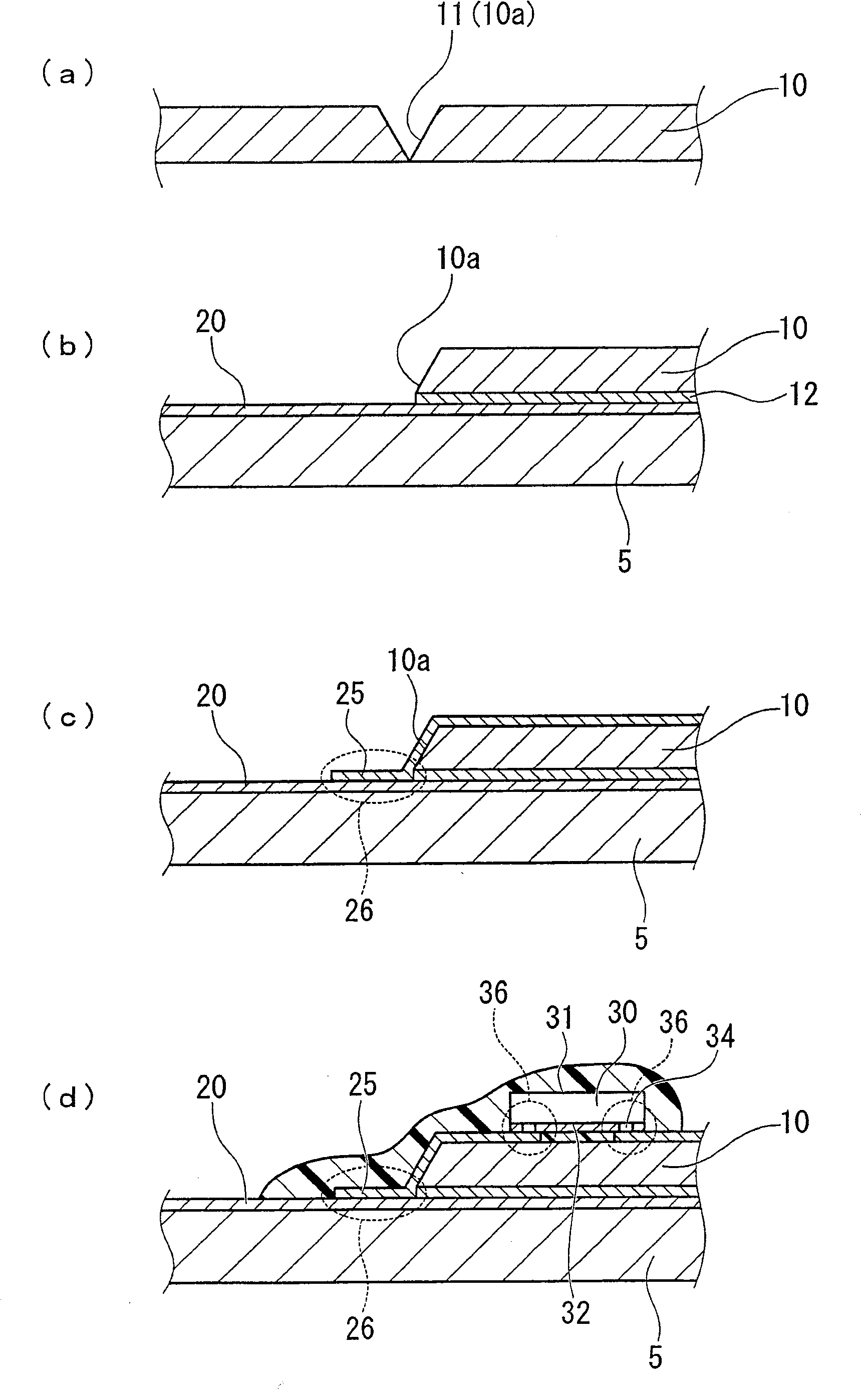

[0107] Figure 5 (a)~(d) means along figure 2 The cross-sectional view taken along the line BB of the elect...

no. 3 approach

[0121] Next, a third embodiment of the electronic device of the present invention will be described.

[0122] Image 6 with Figure 7 It is a figure explaining the electronic device in 3rd Embodiment. Image 6 yes means Figure 7 The side sectional view of the C—C line looking down. Image 6 Symbol 2 in is an electronic device. Figure 7 It is a plan view that sees through a part of the electronic device 1 (resin 35 described later) from the vertical direction, and is a diagram for explaining the electronic device 2 of the present invention. In addition, the same code|symbol is attached|subjected to the component common to the said 1st Embodiment, and detailed description is abbreviate|omitted.

[0123] In the electronic device 2 of the present embodiment, the second wiring 25 of the electronic device 1 of the above-described embodiment covers and is connected to the electrode 34 . Here, the electrode 34 is formed on the electrode surface 32 of the IC chip 30, and is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com