Coil component

A technology of coil components and coils, which is applied in the direction of transformer/inductor parts, electrical components, transformer/inductor coils/windings/connections, etc. It can solve problems such as cracking and composite magnetic body gaps, and achieve high-density installation, The effect of reducing the installation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

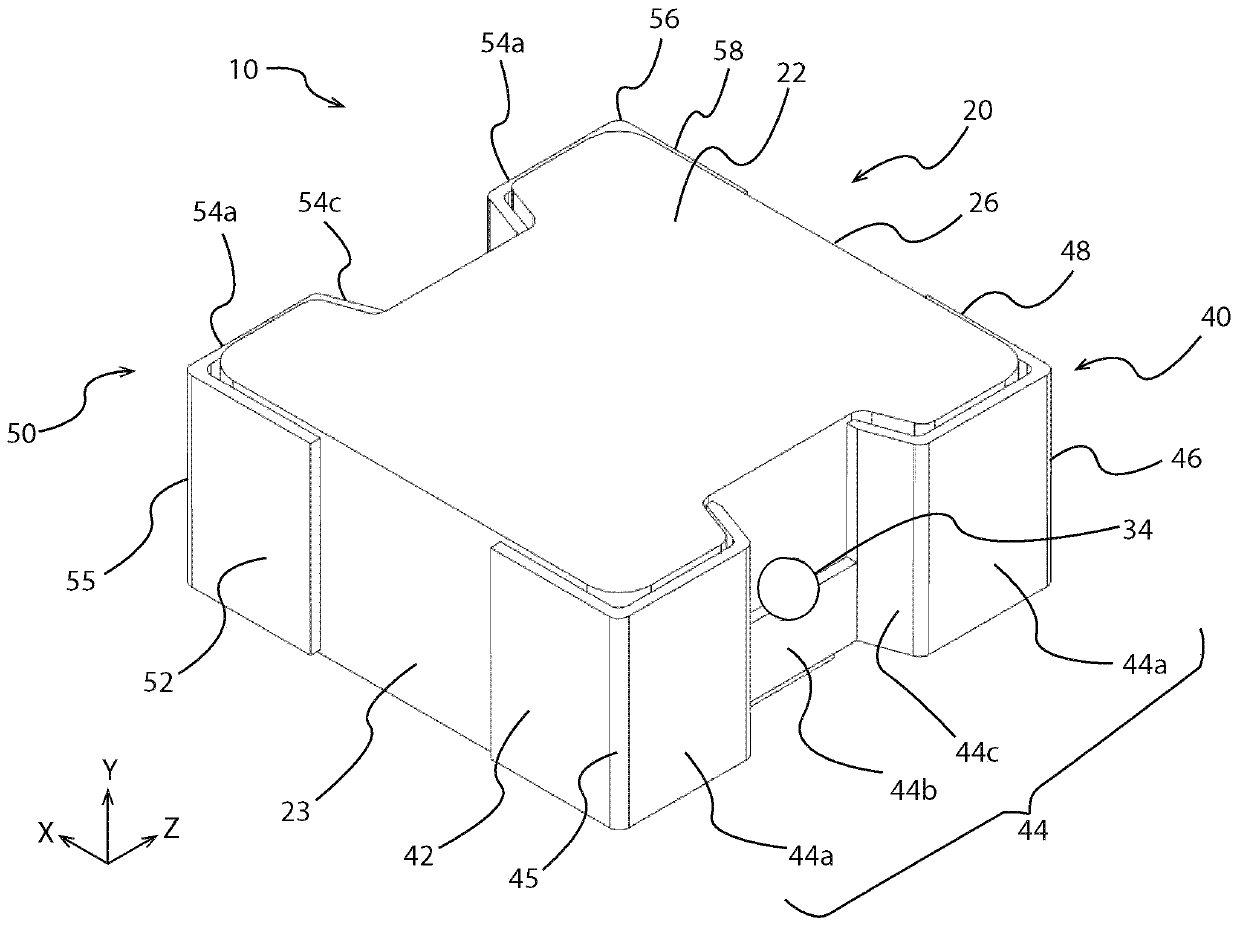

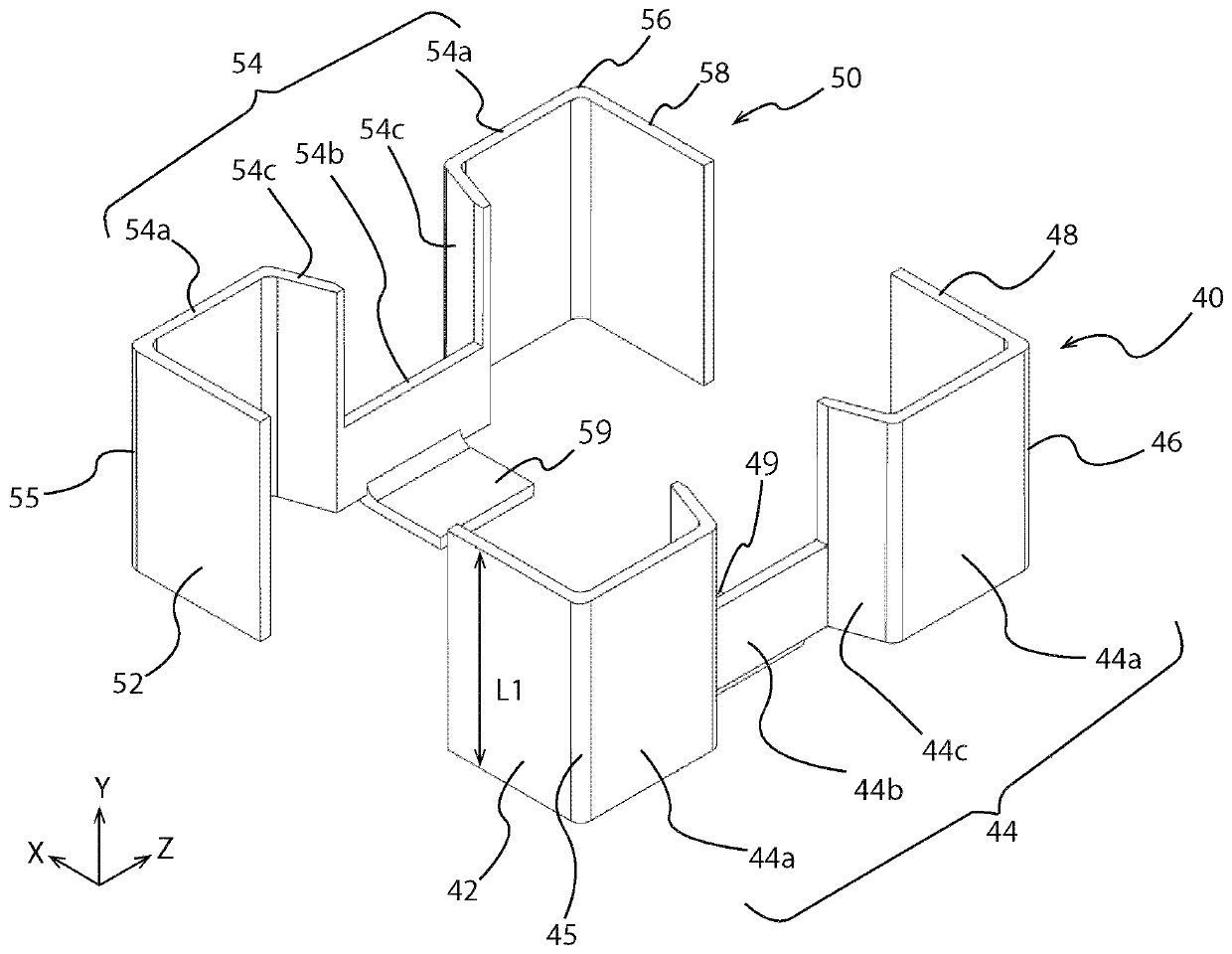

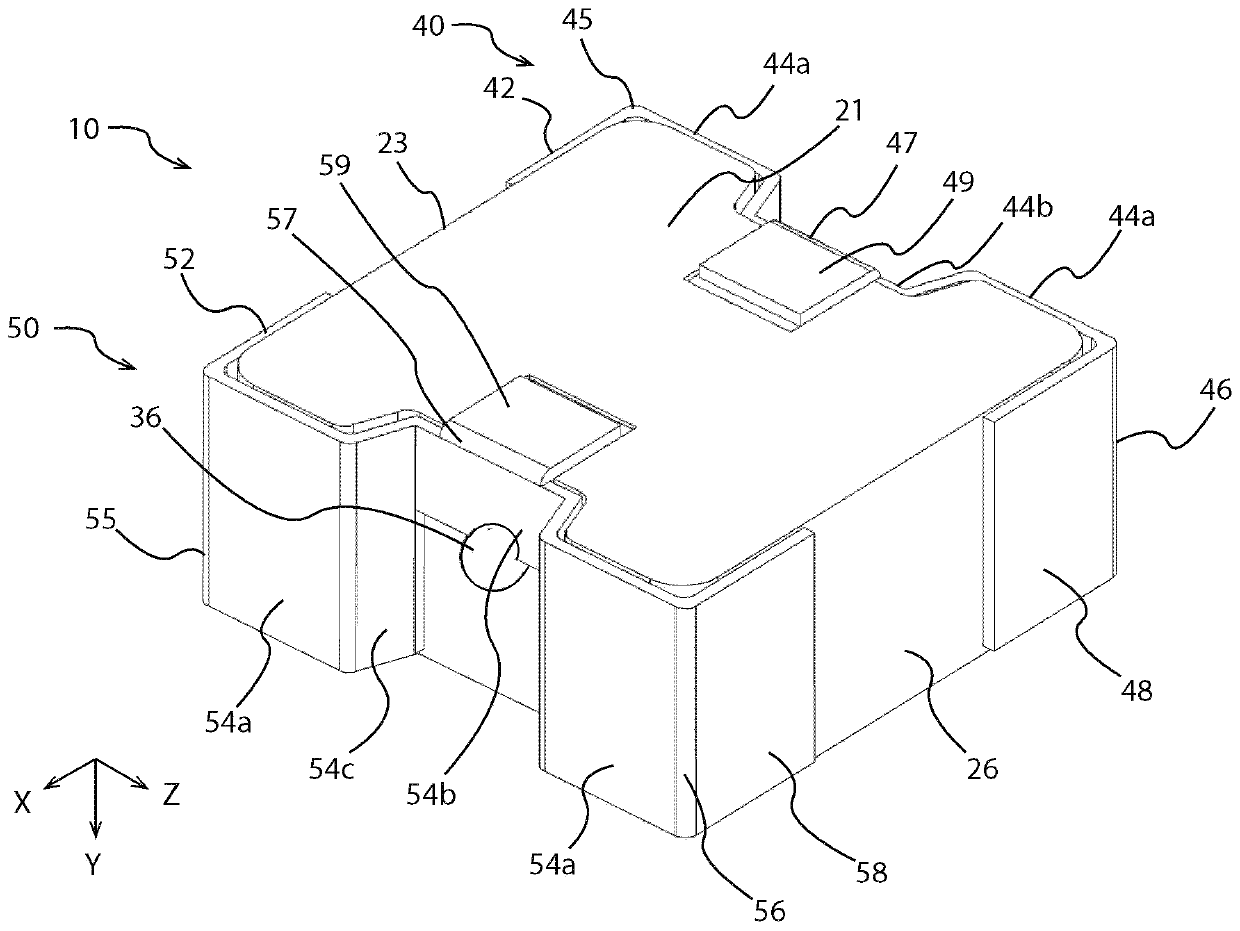

[0133] Figure 7 It is a schematic perspective view from the side of the 2nd surface 22 of the coil component 110 which concerns on 2nd Embodiment of this invention. The coil component 110 according to the second embodiment is the same as the coil component 10 according to the first embodiment except that the shapes of the first and second metal electrodes 140 and 150 are different. Therefore, regarding the coil component 110 according to the second embodiment, only the differences from the coil component 10 will be described, and the description of the same points as the coil component 10 will be omitted.

[0134] Figure 8 yes Figure 7 The perspective view of the first and second metal electrodes 140 and 150 included in the coil component 110 is shown. Such as Figure 8 As shown, the first and second metal electrodes 140, 150 are different from the first and second metal electrodes 40, 50 shown in FIG. Everything else is the same.

[0135] Figure 9 It is a schematic p...

no. 3 approach

[0138] Figure 10 It is a schematic perspective view from the side of the 2nd surface 22 of the coil component 210 which concerns on 3rd Embodiment of this invention. The coil component 210 according to the third embodiment is the same as the coil component 110 according to the second embodiment except that the shapes of the first and second metal electrodes 240 and 250 are different. Therefore, regarding the coil component 210 according to the third embodiment, only the differences from the coil component 110 will be described, and the description of the same points as the coil component 110 will be omitted.

[0139] Composite magnetic body portion 120 of coil component 210 and Figure 7 The composite magnetic body portion 120 included in the illustrated coil component 110 is the same. However, if Figure 10 And the perspective view of the first and second metal electrodes 240, 250 is Figure 11 As shown, the first and second metal electrodes 240 , 250 are different from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com