High-frequency module

A technology of high-frequency modules and metal blocks, which is applied in the fields of magnetic/electric field shielding, circuits, electric solid devices, etc., to achieve the effect of increasing the degree of freedom in design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

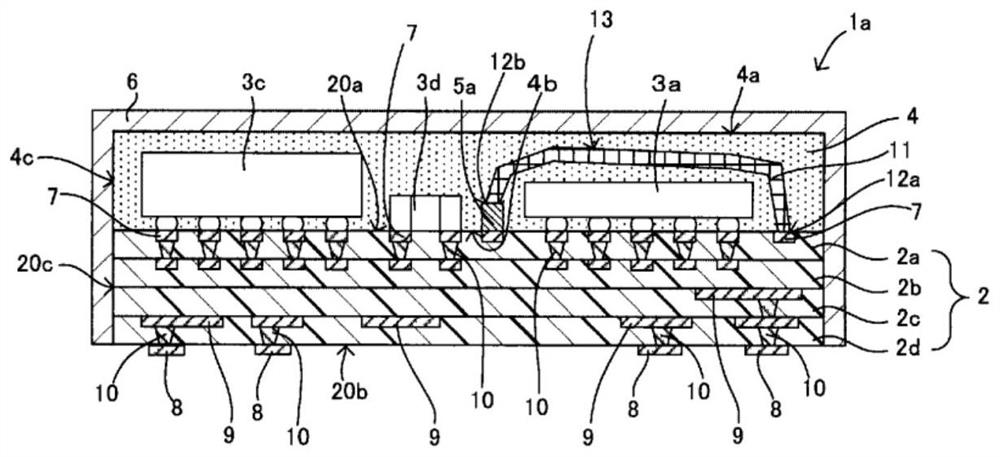

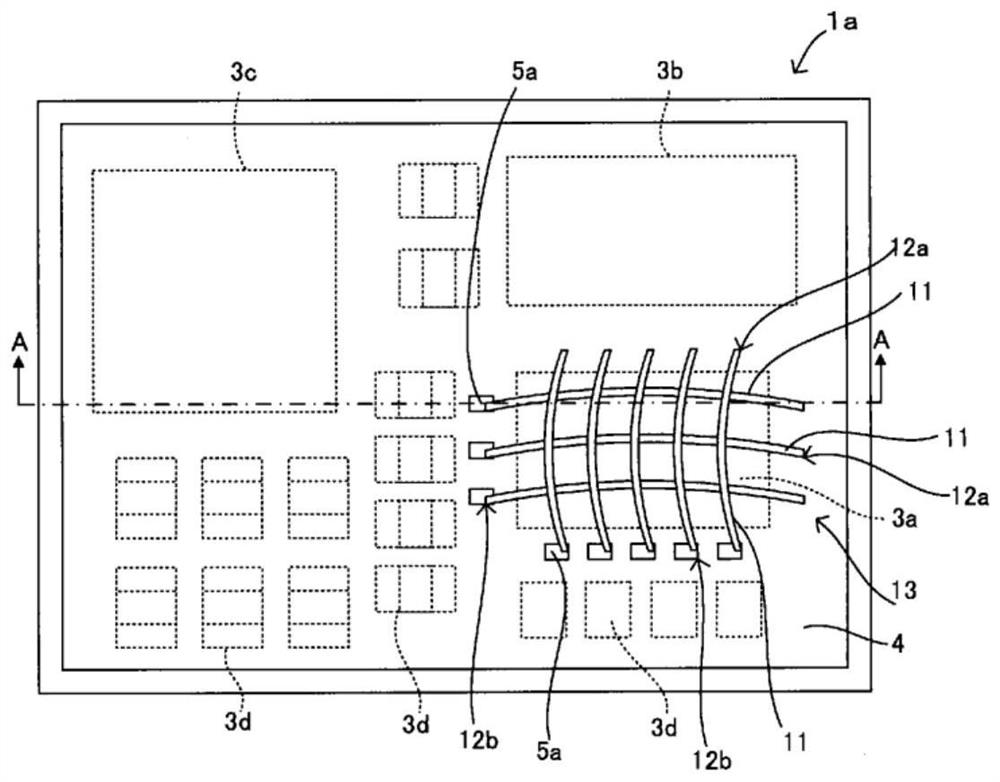

[0038] refer to Figure 1 ~ Figure 2 The high-frequency module 1a according to the first embodiment of the present invention will be described. also, figure 1 yes figure 2 The cross-sectional view in the direction of the A-A arrow, figure 2 It is a top view of the state which removed the shielding film 6 of the high frequency module 1a.

[0039] Such as figure 1 as well as figure 2 As shown, the high-frequency module 1a according to this embodiment includes a multilayer wiring board 2 (corresponding to the "wiring board" of the present invention), and a plurality of components 3a to 3d mounted on the upper surface 20a of the multilayer wiring board 2. , the sealing resin layer 4 laminated on the upper surface 20a of the multilayer wiring board 2, the shielding film 6 covering the surface of the sealing resin layer 4, the plurality of first protruding electrodes 5a mounted on the upper surface 20a of the multilayer wiring board 2, And the bonding wire 11 arranged to ...

no. 2 approach >

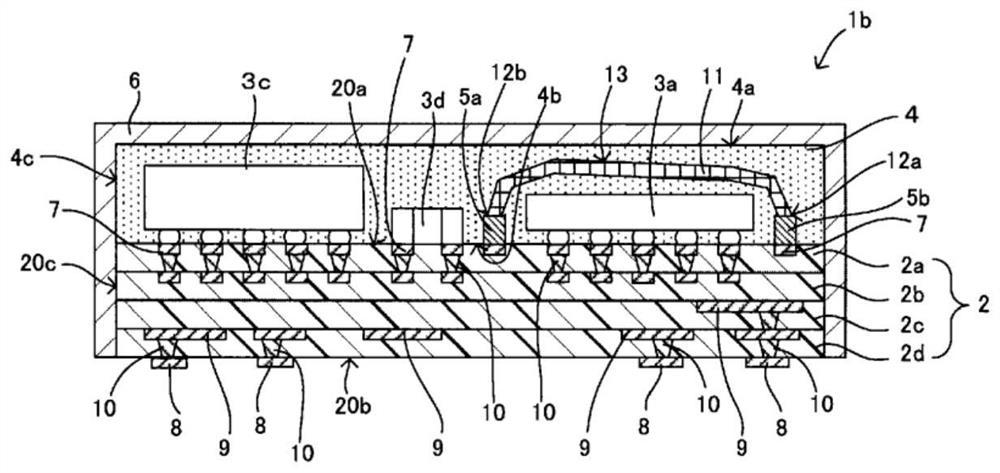

[0052] refer to Figure 3 ~ Figure 4 A high-frequency module 1b according to a second embodiment of the present invention will be described. also, image 3 is a cross-sectional view of the high-frequency module 1b, and is Figure 4 The sectional view of the BB arrow direction, Figure 4 It is a top view of the state which removed the shielding film 6 of the high frequency module 1b.

[0053] Such as Figure 3 ~ Figure 4 As shown, the high-frequency module 1b involved in this embodiment is the same as the reference Figure 1 ~ Figure 2 The high-frequency module 1 a of the first embodiment described above is different in that the second protruding electrode 5 b is arranged at the starting point 12 a (end portion on the first bonding side) of the bonding wire 11 . The other configurations are the same as those of the high-frequency module 1a of the first embodiment, so descriptions thereof will be omitted by denoting the same reference numerals.

[0054] In this embodiment,...

no. 3 approach >

[0061] refer to Figure 7 ~ Figure 8 A high-frequency module 1e according to a third embodiment of the present invention will be described. also, Figure 7 is a cross-sectional view of the high-frequency module 1e, and is Figure 8 The cross-sectional view in the direction of the arrow C-C, Figure 8 is removed Figure 7 A top view of the state after the masking film 6.

[0062] Such as Figure 7 as well as Figure 8 As shown, the high-frequency module 1e involved in this embodiment is the same as the reference Figure 1 ~ Figure 2 The high-frequency module 1a of the first embodiment described is different in that a plurality of bonding wires 11b are arranged along the periphery of the member 3a to surround the member 3a when viewed from a direction perpendicular to the upper surface 20a of the multilayer wiring board 2. at this point. The other configurations are the same as those of the high-frequency module 1a of the first embodiment, so descriptions thereof will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com