Construction method for increasing dry auger boring pouring pile bearing capacity

A technology of auger drilling and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of increasing project cost, large diameter of cast-in-place pile, and difficult construction, etc., and achieves reduction of project cost and single pile bearing capacity The effect of power improvement and no mud pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

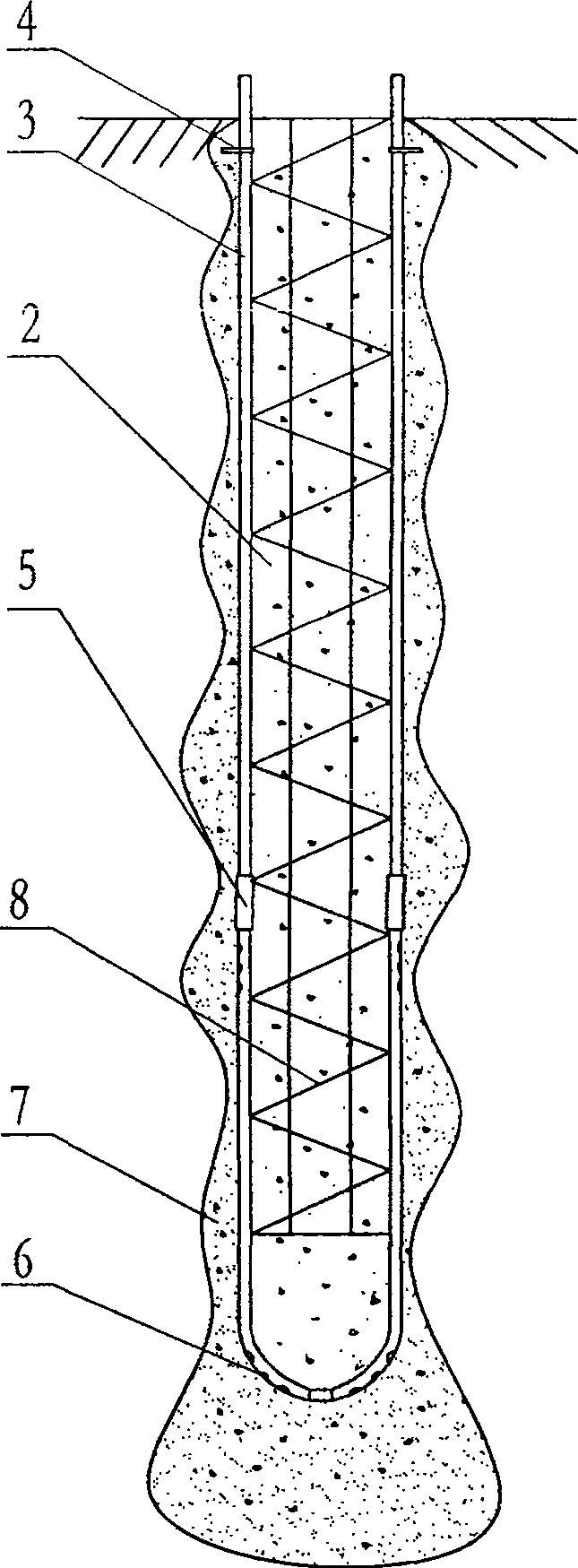

[0009] The construction method for improving the bearing capacity of dry auger bored piles. The pile length is designed above the groundwater level, and the auger drill is used to dry drill the hole to the design depth, and the virtual soil scattered at the bottom of the hole is compacted with a rammer; Two grouting pipes 3 are symmetrically fixed on the side wall of 1 by using U-shaped clips 4. The grouting pipes 3 are PVC plastic hard pipes with a diameter of 20mm, and there are connections on the grouting pipes at the lower 1 / 3 height of the pile hole. The lower end of the grouting pipe 3 bends toward the center of the pile hole and contacts the bottom of the hole, and the side of the grouting pipe 3 that is 10 cm below the one-way valve 5 and contacts the wall of the pile hole is processed with a 6 small grouting holes 6 with a diameter of 4 mm, and 6-8 small grouting holes 6 with a diameter of 5 mm are processed on the side where the curved part of the lower part of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com