Synthesis method for anti-napping and anti-pilling conditioning agent for fabric

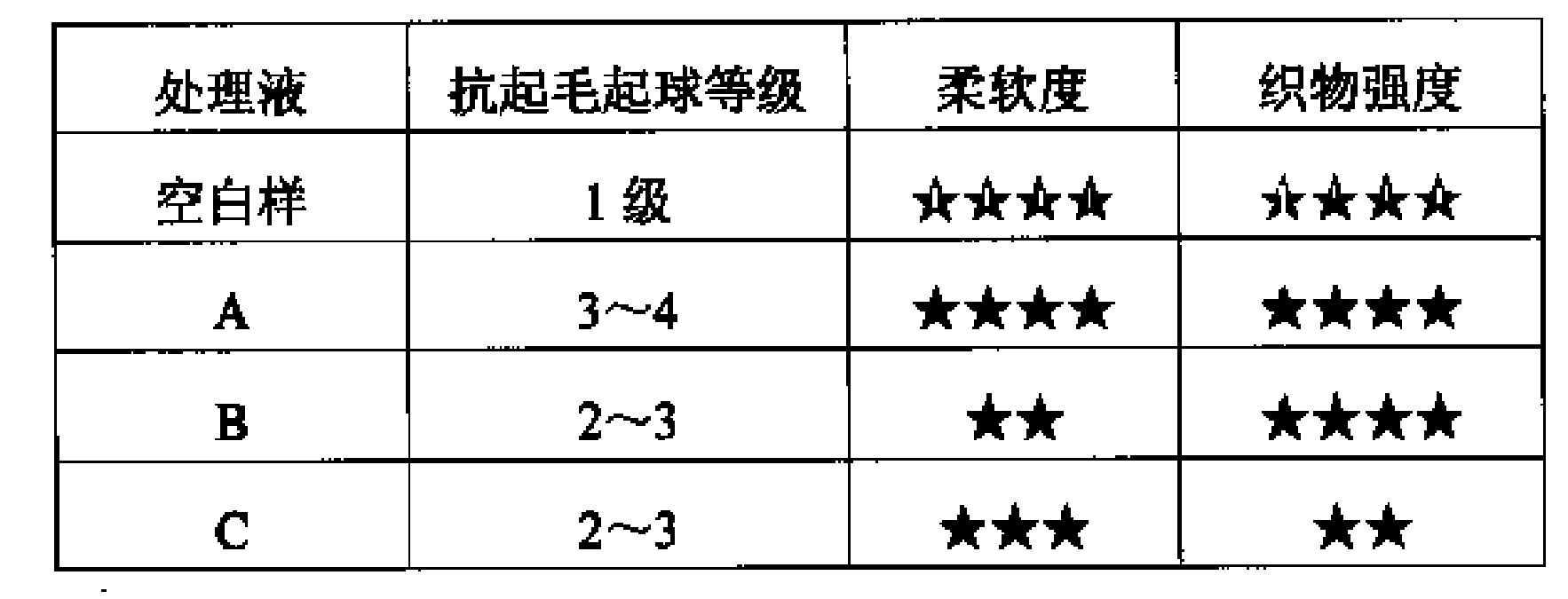

An anti-pilling, synthetic method technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of loss of original style of cashmere or wool, weakened fiber slip, and reduced directional friction effect of cashmere fibers, and achieve excellent anti-pilling effect. The effect of pilling, pilling improvement, and appearance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] 1. Synthesis part

[0020] Step 1: Preparation of Special Anionic Silicone Emulsion

[0021] In a 2000ml three-necked flask equipped with a stirrer and a heating mantle, add 230g of octamethylcyclotetrasiloxane, 52g of dodecylbenzenesulfonic acid, methacryloyloxypropylmethyldimethoxysilane 32 g, 1188 g of deionized water, heated to 76° C. under stirring, and kept for 6 hours to obtain a translucent anionic emulsion.

[0022] Step 2: Preparation of Silicone-Modified Acrylate Emulsion

[0023] Preparation of initiator: ammonium persulfate and sodium bisulfite are respectively prepared into a 3% aqueous solution, and then the two are mixed in equal proportions to prepare 80 g.

[0024] Preparation of pre-emulsion: in a 500ml three-necked flask equipped with a stirrer and a heating mantle, add 12g of emulsifier, add 80g of deionized water, start stirring and heat up to 30°C, and add the mixed monomer ethyl acrylic acid through the dropping funnel. Esters 26.6g, butyl acr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com