Interface preparation method for polynaphthalenediamine sub-micron particles

A polynaphthalene diamine submicron, naphthalene diamine technology is applied in the field of preparation of polynaphthalene diamine, which can solve the problems of restricting wide application and insolubility, and achieve the effects of surface purity, good yield and universal applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

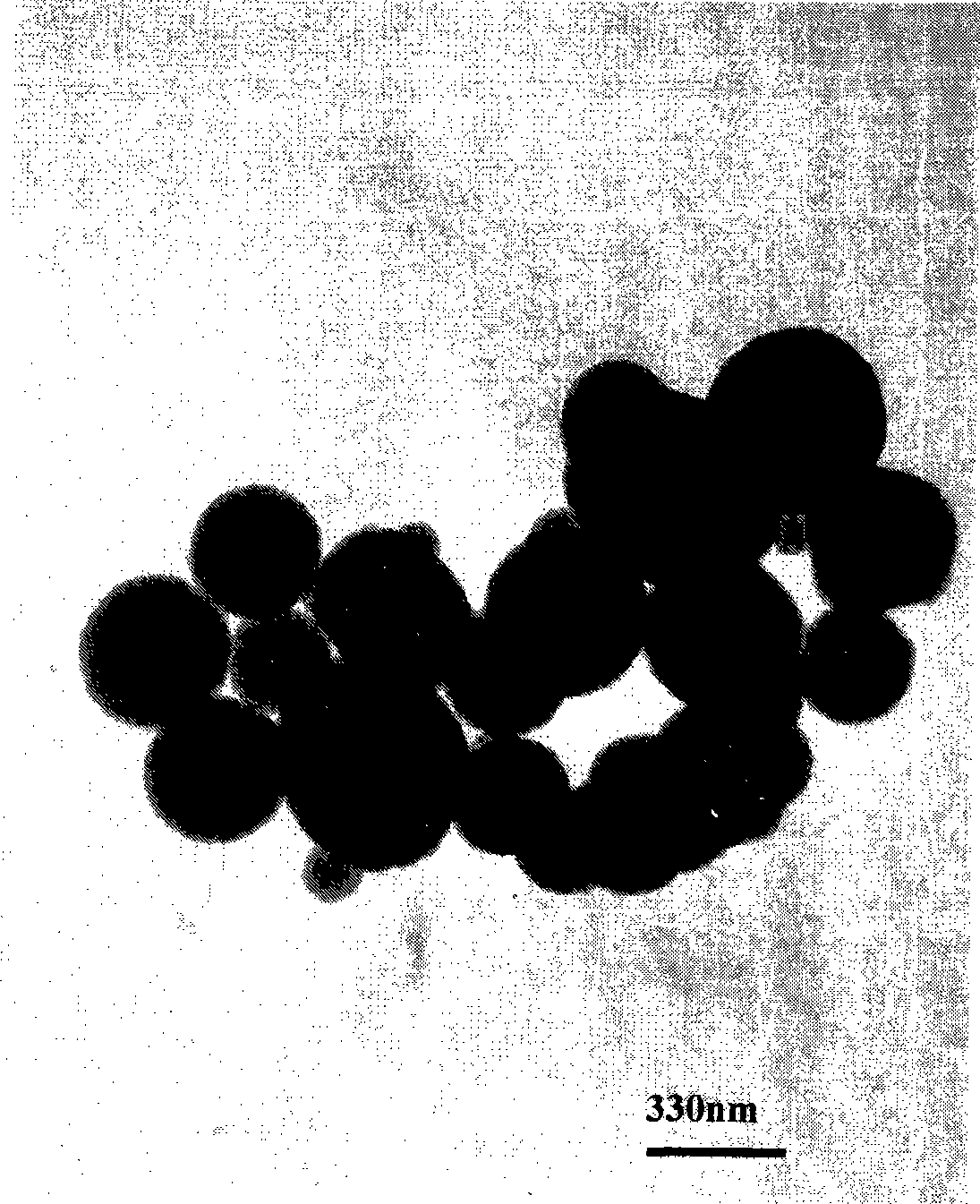

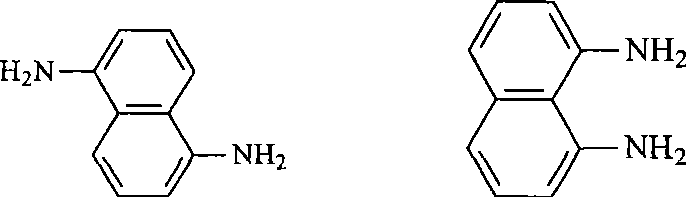

[0020] Accurately weigh 0.158g of 1,5-naphthalene diamine and dissolve it in 20mL of propylene carbonate, then weigh 0.228g of ammonium persulfate and dissolve it in 20mL of 2mol / L nitric acid aqueous solution. After lowering the temperature of the two solutions to 0°C at the same time, slowly add the acid solution dissolved in the oxidizing agent on top of the organic phase, and let it stand still so that the monomer and the oxidizing agent react on the interface for 24 hours. After the reaction, the resulting poly-1,5-naphthalenediamine mixture was poured into a beaker to terminate the reaction with 1 L of deionized water, filtered, and dried to obtain a tan polymer powder with a yield of 35%. The obtained poly-1,5-naphthalene diamine particles have a particle size of 150nm to 300nm, and its transmission electron microscope photo is shown in figure 1 .

Embodiment 2

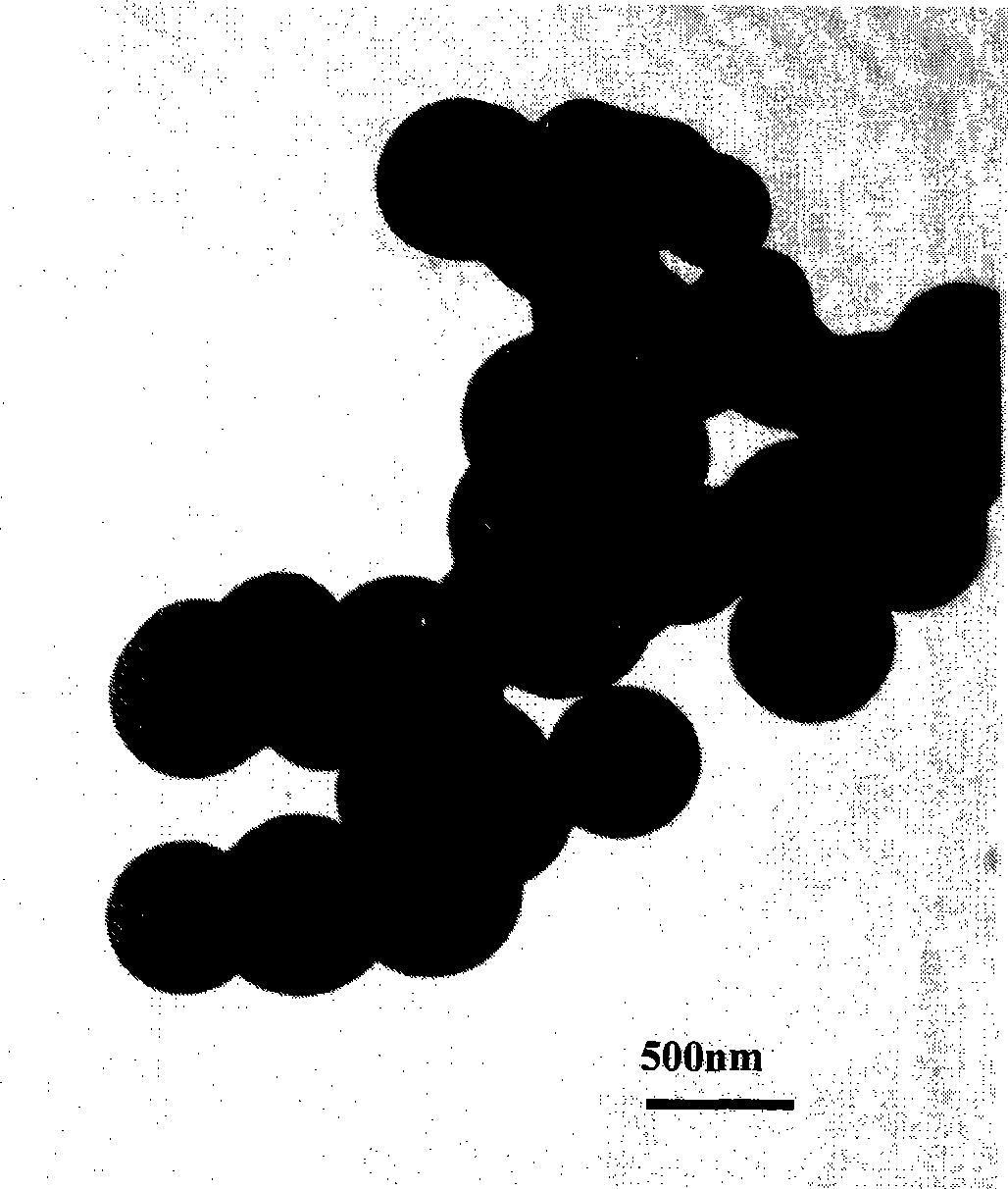

[0022] Accurately weigh 0.158g of 1,5-naphthalene diamine and dissolve it in 20mL of propylene carbonate, then weigh 0.228g of ammonium persulfate and dissolve it in 20mL of 2mol / L perchloric acid aqueous solution. After lowering the temperature of the two solutions to 0°C at the same time, slowly add the acid solution dissolved in the oxidizing agent on top of the organic phase, and let it stand still so that the monomer and the oxidizing agent react on the interface for 24 hours. After the reaction, the resulting poly-1,5-naphthalenediamine mixture was poured into a beaker to terminate the reaction with 1 L of deionized water, filtered, and dried to obtain a tan polymer powder with a yield of 42%. The prepared poly-1,5-naphthalene diamine particles are uniform in size, with particle diameters ranging from 300nm to 400nm. figure 2 .

Embodiment 3

[0024] Accurately weigh 0.158g of 1,8-naphthalene diamine and dissolve it in 20mL of propylene carbonate, then weigh 0.228g of ammonium persulfate and dissolve it in 20mL of 2mol / L perchloric acid aqueous solution. After lowering the temperature of the two solutions to 5° C., slowly add the acid solution dissolved in the oxidizing agent on top of the organic phase and let it stand still so that the monomer and the oxidizing agent react on the interface for 24 hours. After the reaction, the resulting poly-1,5-naphthalenediamine mixture was poured into a beaker to terminate the reaction with 200 mL of deionized water, filtered, and dried to obtain a tan polymer powder with a yield of 31%. Observation by TEM shows that the particle diameter of the prepared poly-1,5-naphthalene diamine particles is 300nm-400nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com