Lathing method for Semi-circle bush

A processing method and semi-circular shaft technology, applied in turning equipment, metal processing, metal processing equipment, etc., can solve the problems that the surface roughness of parts is difficult to meet the design requirements, the dimensional accuracy, the shape and position dimensional accuracy are difficult to guarantee, and the dimensional accuracy is affected. , to achieve the effect of reducing alignment time, improving processing quality, and selecting reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] 1. Clamping of parts

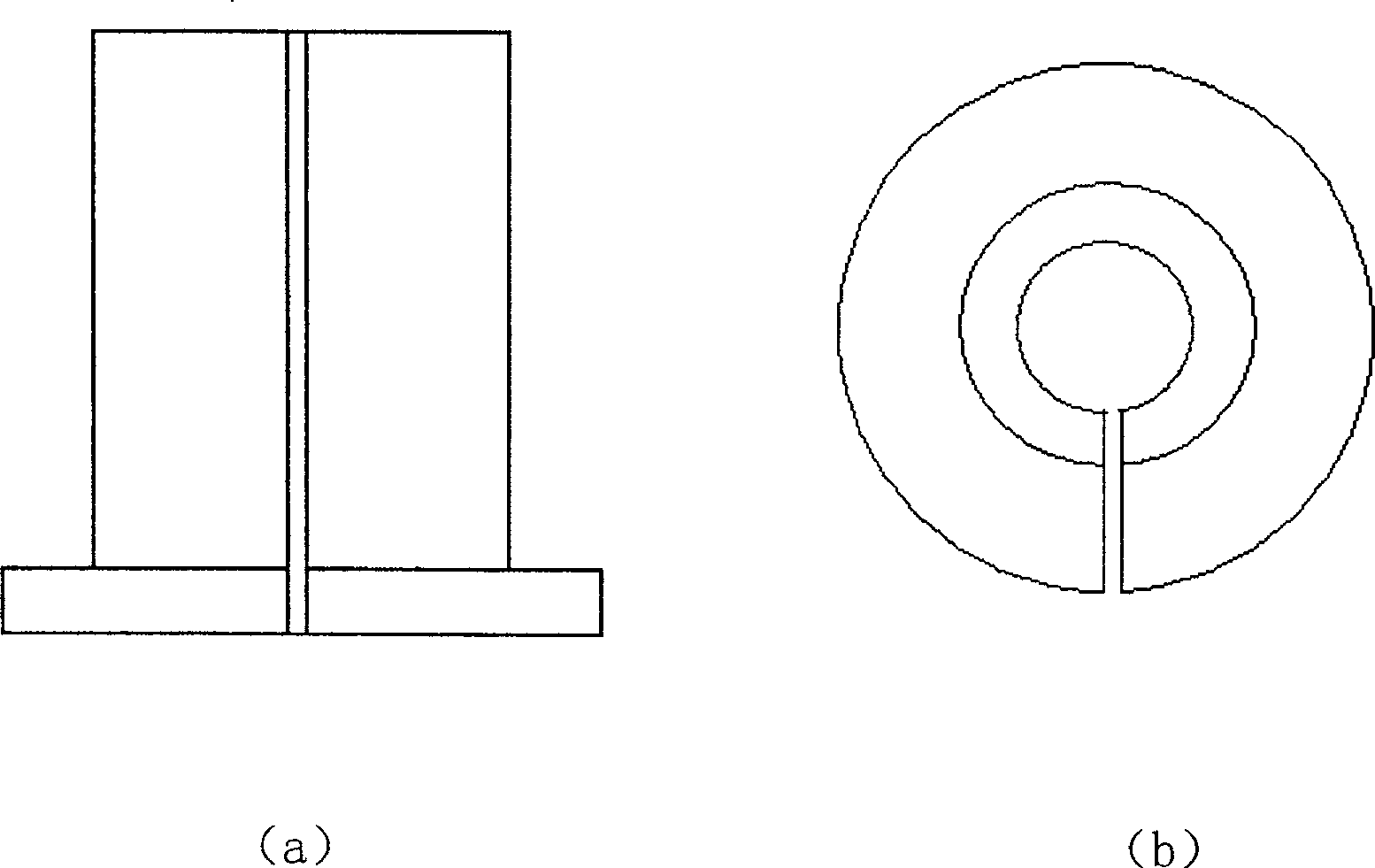

[0029] 1. First, according to the different dimensions of the outer diameter of the drawing of the semicircular bearing bush, design and manufacture a slotted sleeve fixture with the same diameter as the part and a slot in the middle (such as figure 1 As shown), the material for making the slotted clamp is preferably cast iron.

[0030] 2. According to the size requirements of the parts and the already-made slit sleeve fixture, the blank of the part to be processed is chucked.

[0031] 3. Put the chuck in the part into the inner hole of the slotted sleeve, clamp it together with the slotted sleeve on the three-jaw automatic centering chuck, and perform subsequent turning processing after clamping.

[0032] Two, rough car

[0033] Since the machining allowance of the general blank is relatively large, if the number of parts to be processed is relatively large, it is necessary to perform a rough turning process on the turned parts, cutting off a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com