Method for preparing low hydrogen type downwards electrode

A low-hydrogen type, welding rod technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of difficult welding, slag dripping, low temperature, etc., and achieve stable arc combustion and easy slag removal , Good low temperature impact toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

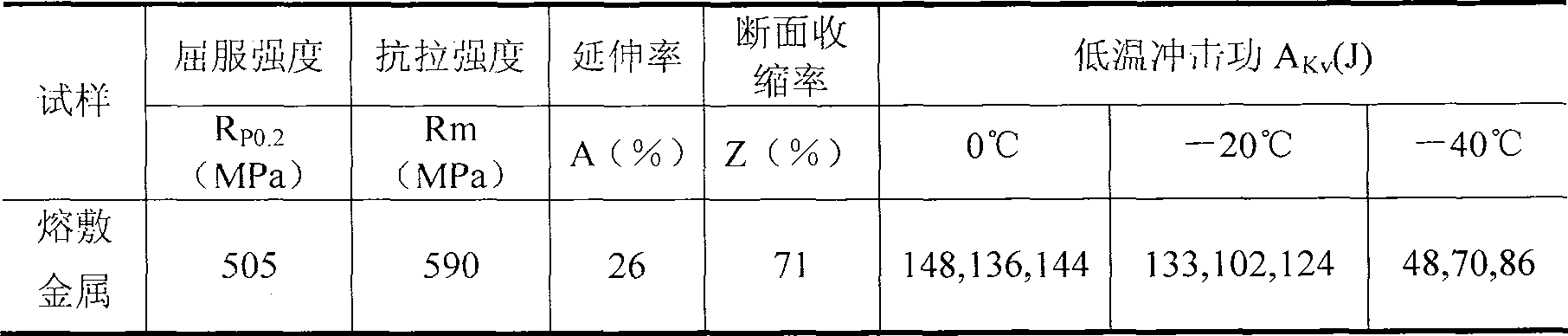

[0033] The low-hydrogen type downward welding electrode uses commercially available H08E steel wire as its core, and the outer layer is coated with a coating to form the electrode, and the weight of the coating accounts for 35-50% of the weight of the electrode;

[0034] In its medicine: CaCO 3 25%, TiO 2 20%, CaF 2 17%, SiO 2 7%, Al 2 O 3 5%, ferro-titanium 4%, ferrosilicon 4%, manganese powder 8%, iron powder 10%.

Embodiment 2

[0036] The low-hydrogen type downward welding electrode uses commercially available H08E steel wire as its core, and the outer layer is coated with a coating to form the electrode, and the weight of the coating accounts for 35-50% of the weight of the electrode;

[0037] In its medicine: CaCO 3 33%, TiO 2 10%, CaF 2 20%, SiO 2 5%, Al 2 O 3 6%, ferro-titanium 5%, ferrosilicon 4%, ferromolybdenum 1%, nickel powder 1%, manganese powder 6%, iron powder 9%.

Embodiment 3

[0039] The low-hydrogen type downward electrode, the welding core adopts commercially available H08E steel wire, and the outer layer is coated with a coating to become the electrode, and the weight of the coating accounts for 35-50% of the weight of the electrode;

[0040] In its medicine: CaCO 3 38%, TiO 2 12%, CaF 2 12%, SiO 2 10%, Al 2 O 3 3%, ferro-titanium 7%, ferrosilicon 6%, ferromolybdenum 2%, nickel powder 1%, manganese powder 2%, iron powder 7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com