A kind of double-layer medicine skin of arc planing cutting strip and preparation method thereof

An arc planing and coating technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., to increase the length, increase the arc blowing force, and prevent the coating from failing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

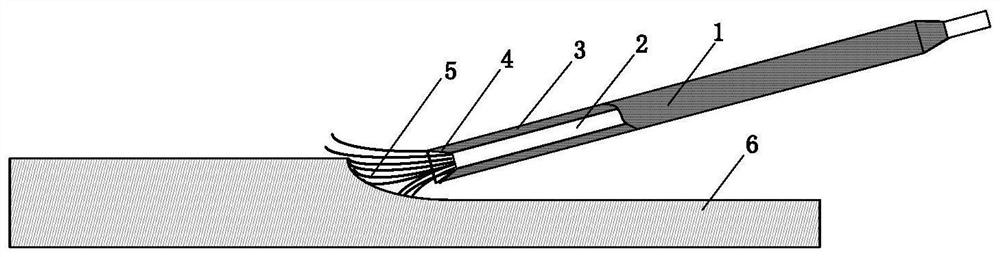

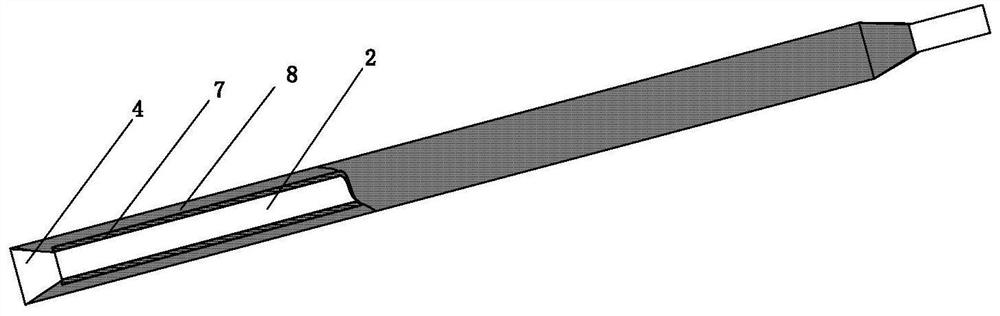

[0025] A kind of electric arc planing strip of double-layered skin, including inner layer of skin 7 and outer skin 8; The mass ratio of the inner layer of the skin 7 using raw materials is: 45 parts bauxite, 8 parts talc, 10 parts titanium dioxide;

[0026]The outer layer of the skin 8 using the mass ratio of raw materials is: 20 parts of microcrystalline cellulose, 5 parts of wood powder, 8 parts of rutile, 5 parts of graphite, 3 parts of iron sand, 5 parts of rhombus bitter soil, 5 parts of white mud.

[0027] Preparation method of double-layer medicinal skin of arc planing cutting strip, comprising the following steps:

[0028] Step 1, according to the mass of the number of components ratio to take the following components: 45 parts bauxite, 8 parts talc, 10 parts titanium dioxide, mix evenly, and then add 30% of the total mass of the inner layer of the skin component of the sodium water glass mixed evenly, pressed on the weld core 2, dried to form a 0.3mm inner layer of the sk...

Embodiment 2

[0031] A kind of electric arc planing strip of double-layered skin, including inner layer of skin 7 and outer skin 8; The mass ratio of the inner layer of the skin 7 using raw materials is: 65 parts bauxite, 12 parts talc, 15 parts titanium dioxide;

[0032] The outer layer of the coating 8 using the mass ratio of raw materials is: 26 parts of microcrystalline cellulose, 8 parts of wood flour, 11 parts of rutile, 9 parts of graphite, 4 parts of iron sand, 10 parts of rhombus bitter soil, 7 parts of white mud.

[0033] Preparation method of double-layer medicinal skin of arc planing cutting strip, comprising the following steps:

[0034] Step 1, according to the ratio of mass parts to take the following components: 65 parts bauxite, 12 talc, 15 parts titanium dioxide, mix evenly, and then add 35% of the total mass of the inner layer of the skin component of the sodium water glass to mix evenly, pressed on the weld core 2, dried to form a 0.5mm inner layer of the skin 7

[0035] Ste...

Embodiment 3

[0037]A kind of electric arc planing strip of double-layered skin, including inner layer of skin 7 and outer skin 8; The inner layer of the skin 7 uses the mass ratio of raw materials as follows: 51 parts bauxite, 9 parts talc, 12 parts titanium dioxide;

[0038] The outer layer of the skin 8 using the mass ratio of raw materials is: 30 parts of microcrystalline cellulose, 10 parts of wood powder, 12 parts of rutile, 10 parts of graphite, 5 parts of iron sand, 12 parts of rhombus bitter soil, 8 parts of white mud.

[0039] Preparation method of double-layer medicinal skin of arc planing cutting strip, comprising the following steps:

[0040] Step 1, according to the ratio of mass parts to take the following components: 51 parts bauxite, 9 parts talc, 12 parts titanium dioxide, mix evenly, and then add 40% of the total mass of the inner layer of the skin component of the sodium water glass to mix evenly, pressed on the weld core 2, dried to form a 0.4mm inner layer of the skin 7;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com