Organosilicon modified carbonyl epoxy composite material

A composite material, carbonyl epoxy technology, applied in the field of organosilicon modified carbonyl epoxy composite materials, can solve the problems of poor flow performance, affecting mechanical properties and uniform stability performance, poor surface performance water resistance and weather resistance, etc. Good performance and permeability, uniform and stable mechanical properties, high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

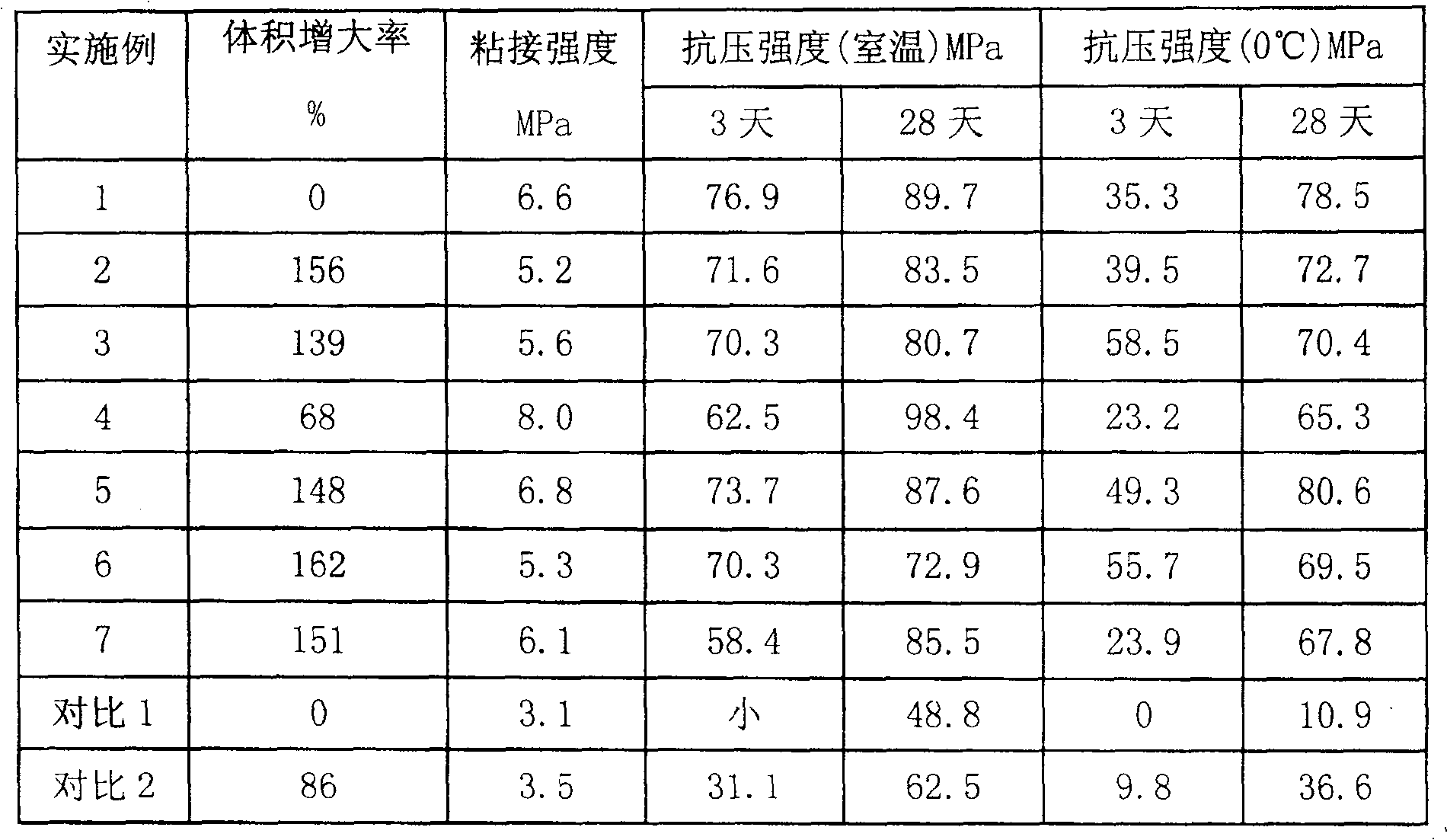

Examples

Embodiment 1

[0017]Add 40g of E-44 bisphenol A type epoxy resin into the reactor, add 10g of silicone methyl hydrogen-containing silicone oil and 0.3g of di-n-butyltin dilaurate, heat up to 100-120°C under stirring, and react for 5 hours , placed and cooled to obtain 50g of silicone chemically modified epoxy resin, and then mixed with 40g of benzaldehyde and 10g of silane coupling agent γ-epoxypropyltriethoxysilane to obtain component A. Mix 100 g of diethylenetriamine, 150 g of acetone, and 10 g of tetrabutylammonium hydroxide and leave it at room temperature for 2 hours to obtain component B. 100 g of component A and 30 g of component B were evenly mixed to obtain 130 g of the silicone-modified carbonyl epoxy composite material of the present invention as an organic mixed glue.

Embodiment 2

[0019] Take 100 g of the organic mixed glue in Example 1, add 50 g of cement and 450 g of river sand, mix and stir evenly, and obtain 600 g of organosilicon-modified carbonyl epoxy composite material.

Embodiment 3

[0021] First add 50g of polyurethane prepolymer and 100g of glycerin epoxy resin B-63 (epoxy value 0.55-0.71mol / 100g) into the reactor, heat up to 130-140°C under stirring, keep warm for 2 hours, and cool to prepare Polyurethane modified epoxy resin. Then take 50g of polyurethane-modified epoxy resin, 40g of furfural, and 10g of aminoalkyl silicone oil and mix them uniformly at room temperature to obtain component A. Separately take 100 g of triethylenetetramine, 150 g of diacetone alcohol and 5 g of tetramethylammonium hydroxide, mix them uniformly, and place them at room temperature for 2 hours to obtain component B. Mix 30g of component B with 100g of component A, take out 100g, add 90g of cement and 210g of river sand and stir evenly to obtain 400g of silicone-modified carbonyl epoxy composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com