Waveguide optical switch and making method thereof

A fabrication method and waveguide light technology, which are applied in the directions of optical waveguides and optical waveguides, coupling of optical waveguides, etc., can solve the problems of high switching driving power, complex fabrication process, large insertion loss, etc., and achieve fast response speed, simple fabrication process, and insertion Low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

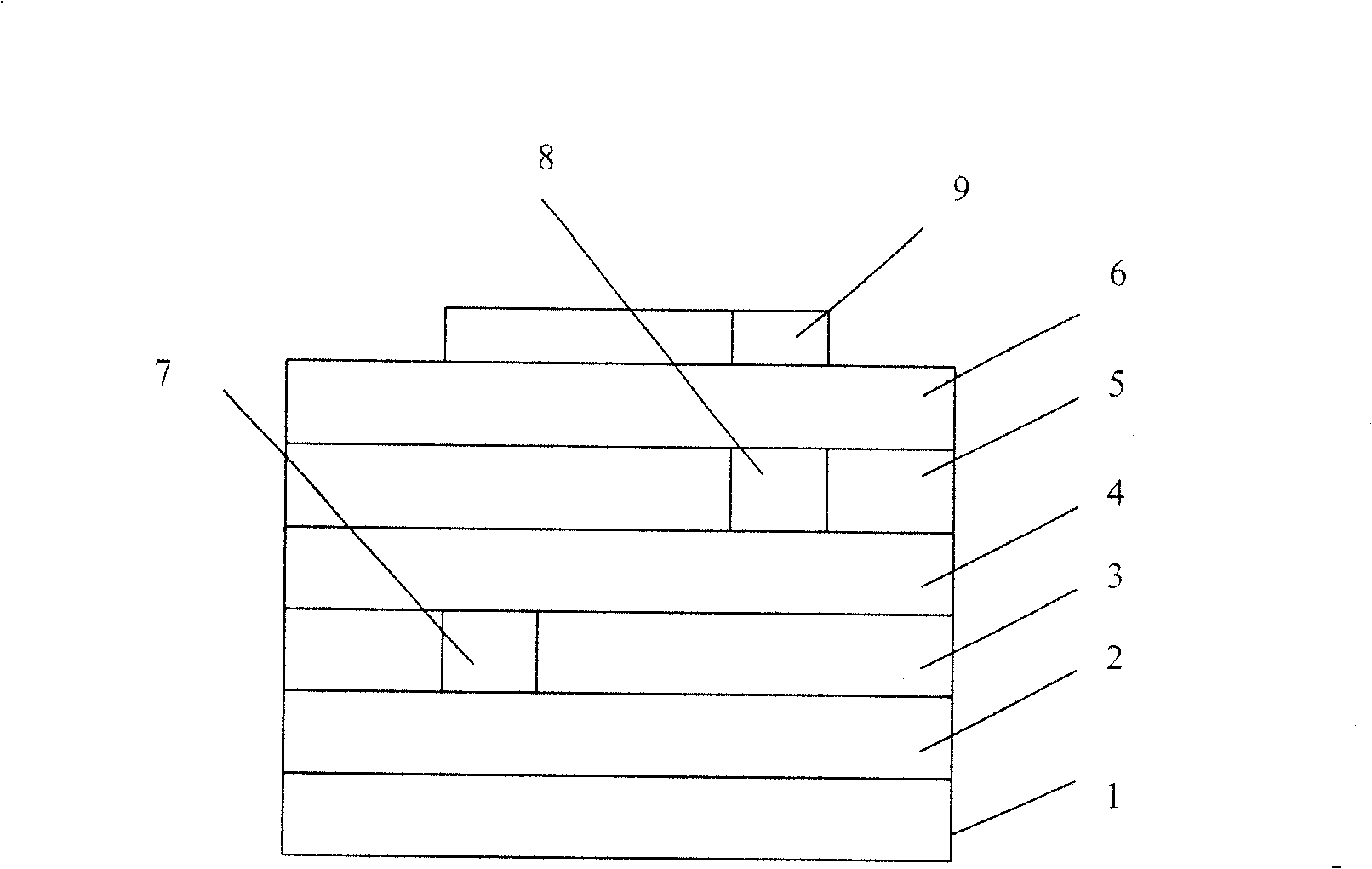

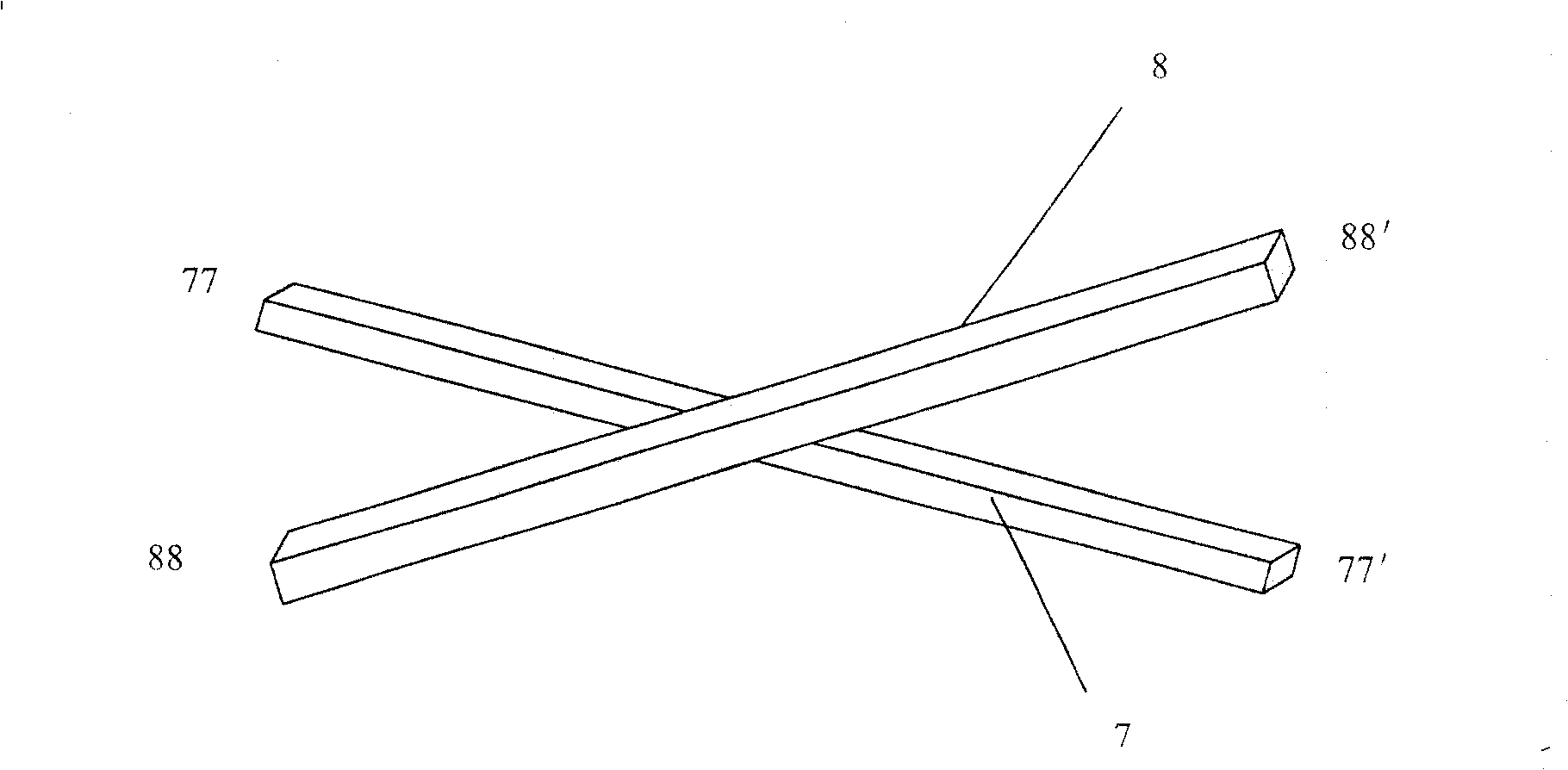

[0023] Such as figure 1 As shown, the present invention adopts a five-layer film structure. From the base silicon chip 1 to the metal electrode 9, the lower waveguide lower cladding layer 2, the lower waveguide core layer, the vertical coupling layer 4 (common cladding layer), the upper waveguide core layer, and the upper waveguide core layer are sequentially formed. Cladding 6 on the waveguide. The base silicon wafer 1 is a high-purity silicon wafer. The lower cladding layer 2 of the lower waveguide is made of polyester polymer BCB, and its thickness can be 3 μm, 4 μm or 5 μm. The thickness of the lower waveguide core layer is 3.6 μm, 3.8 μm, 4.0 μm, or 4.2 μm, including the lower waveguide 7 in this layer and the lower waveguide side cladding 3 around it, and the lower waveguide 7 is made of cyclized rubber polymer Su8 , the lower waveguide side cladding 3 is made of polyester polymer BCB. The vertical coupling layer 4 is made of polyester polymer BCB with a thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com