Simulated moving bed chromatographic focusing

A chromatographic column and injection tube technology, which is applied in the field of invention of different individual components in their respective regions, can solve problems such as low concentration of fractions and improve the problem, and achieve the effects of increasing product yield and purity, increasing yield, and reducing production consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0061] Example 1: Batch gradient chromatography separation of porcine serum

[0062] A chromatographic column with an inner diameter of 4.6 mm and a length of 180 mm was filled with DEAE-Sepharose ion exchange resin (particle size 50 μm, from Pharmacia). The sample is 10mM KCl semi-permeable membrane filtered porcine serum. Add 1ml of sample to the chromatographic column, then elute the chromatographic column with 30ml linear gradient KCl solution (concentration from 0.01M to 0.4M), and collect 30 fractions. These fractions were analyzed by 10% non-modified polyacrylamide gel electrophoresis in the Laemmli buffer system. The greatest amount of albumin occurs in fractions 14-20. A weak band (named component B) co-eluted with albumin in fractions 17 and 18.

example 2

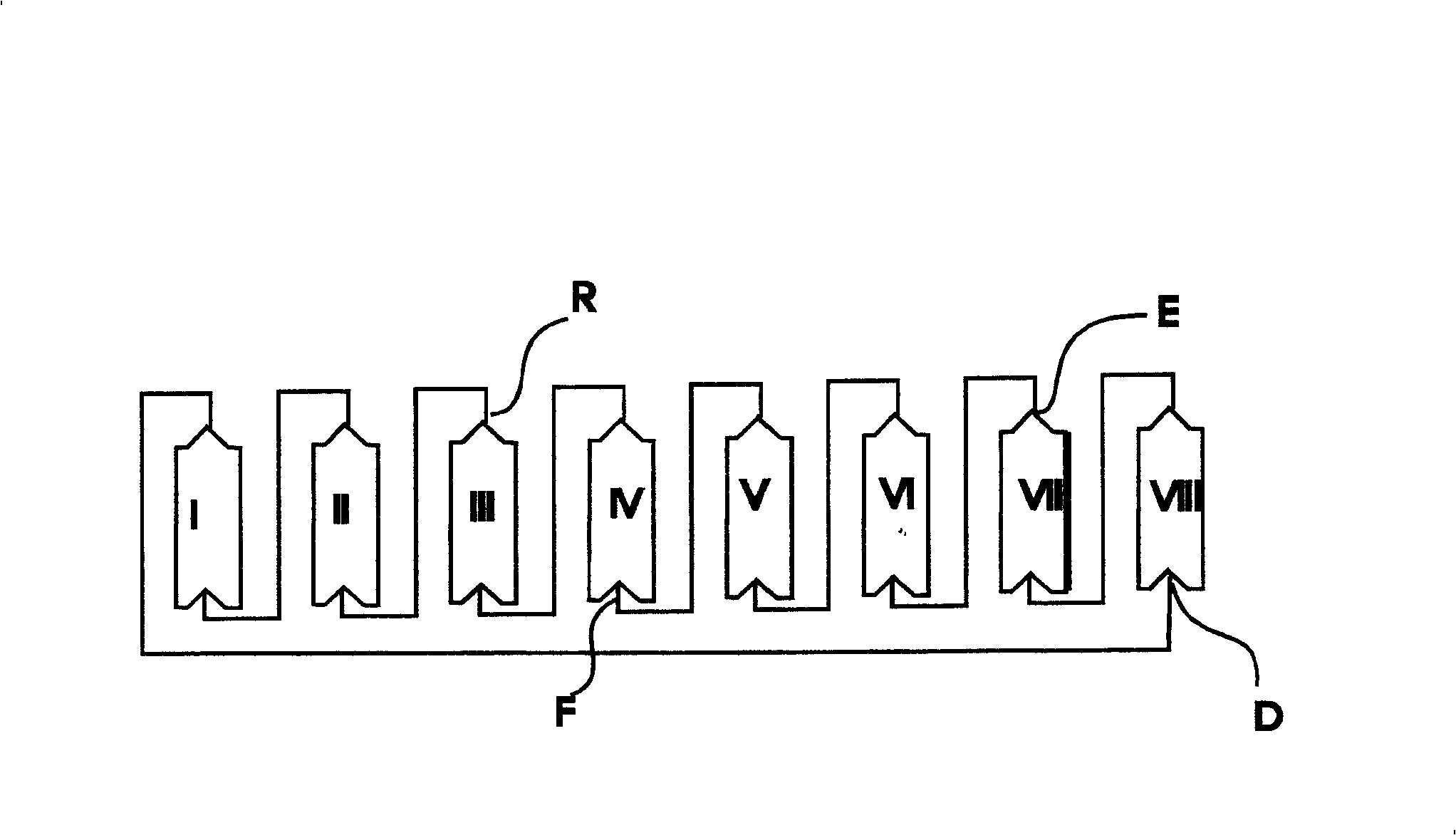

[0063] Example 2: Separation of porcine serum by simulated moving bed focusing chromatography (hereinafter referred to as SMBCF)

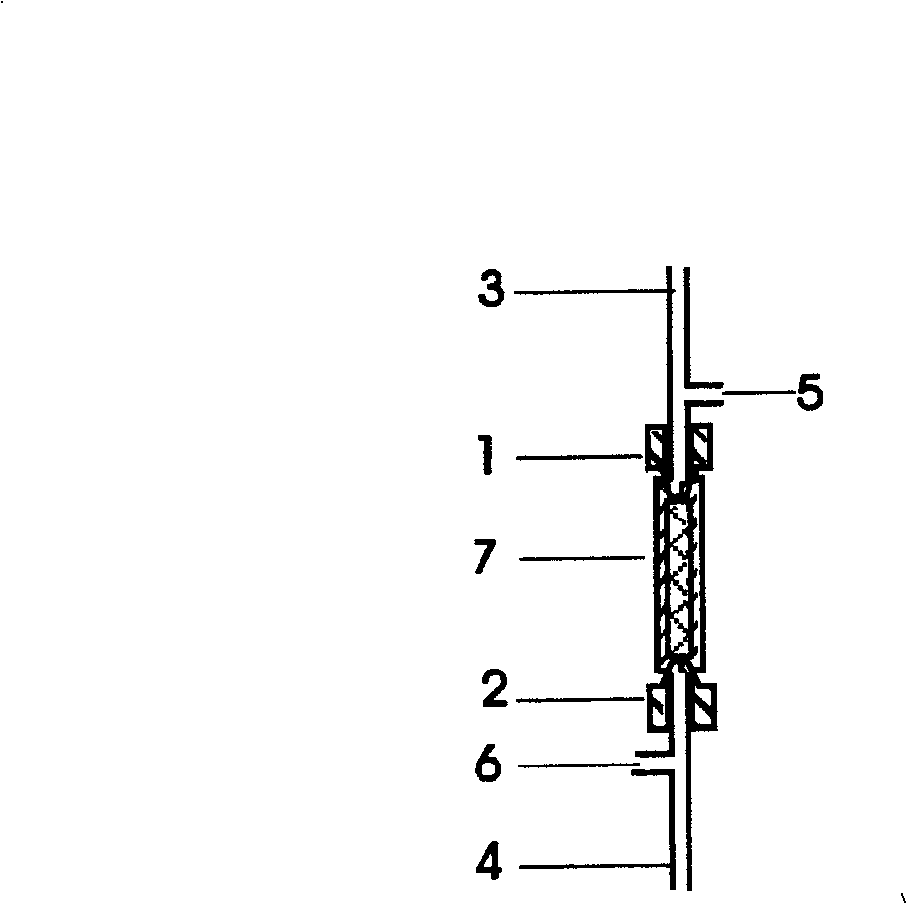

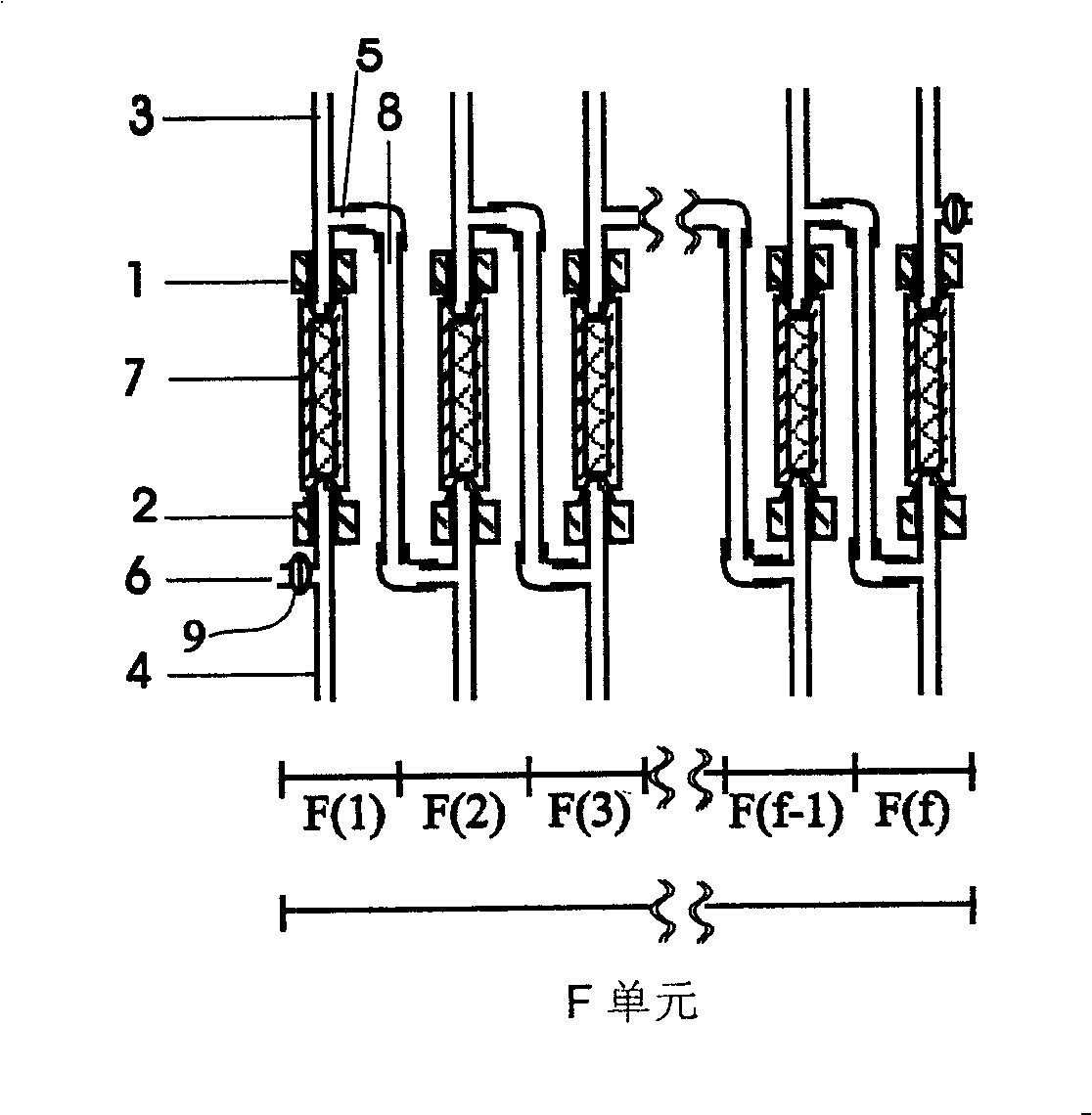

[0064] Such as Figure 5 The form shown constitutes the SMBCF system. Unit F includes 5 areas, and Unit S, Unit B, and Unit R each include one area. There is a chromatographic column (30 mm×4.6 mm, length×inner diameter) in each zone, filled with DEAE-Sepharose ion exchange resin (50 μm, from Pharmacia). system such as Figure 5 Operate as described. Perform a column reset every 1.5 minutes. Pig serum was treated as a sample in the same manner as in Example 1, and see Table 1 for the composition and injection flow rate of the eluate in all 8 zones. The system performs the column reset process 40 times. Each time the chromatographic column is reset, collect all the eluates from the S(1) and F(1) regions; collect 0 from each of the F(2), F(3), F(4), and F(5) regions. .025ml of eluate. Fractions collected at the 10th, 20th, 30th, and 40th colu...

example 3

[0067] Example 3: Separation of SMBCF from porcine serum with fluid harvesting by fluid displacement

[0068] Such as Figure 5 The composition of the SMBCF system is shown. Use the method of Example 2 to separate. However, the liquid collection in the F(3) area is used Figure 8The flow displacement shown was carried out. Liquid was collected every 5 column resets. 0.05ml of 0.17M NaCl solution was used as the replacement solution for each collection. The other liquids were received in the same manner as in Example 2. Fractions collected at the 10th, 20th, 30th, and 40th column resets were analyzed using 10% non-modified polyacrylamide gel electrophoresis under the Laemmli buffer system. Compared with Example 2, the band of component B in the fraction collected in the F(3) area is stronger and the purity is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com