Method of utilizing cracked, C5 fraction

A technology for cracking carbon and fractions, which is applied in the fields of hydrocarbon cracking to hydrocarbon production, hydrogenation to hydrocarbon production, organic chemistry, etc., to achieve the effect of saving hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

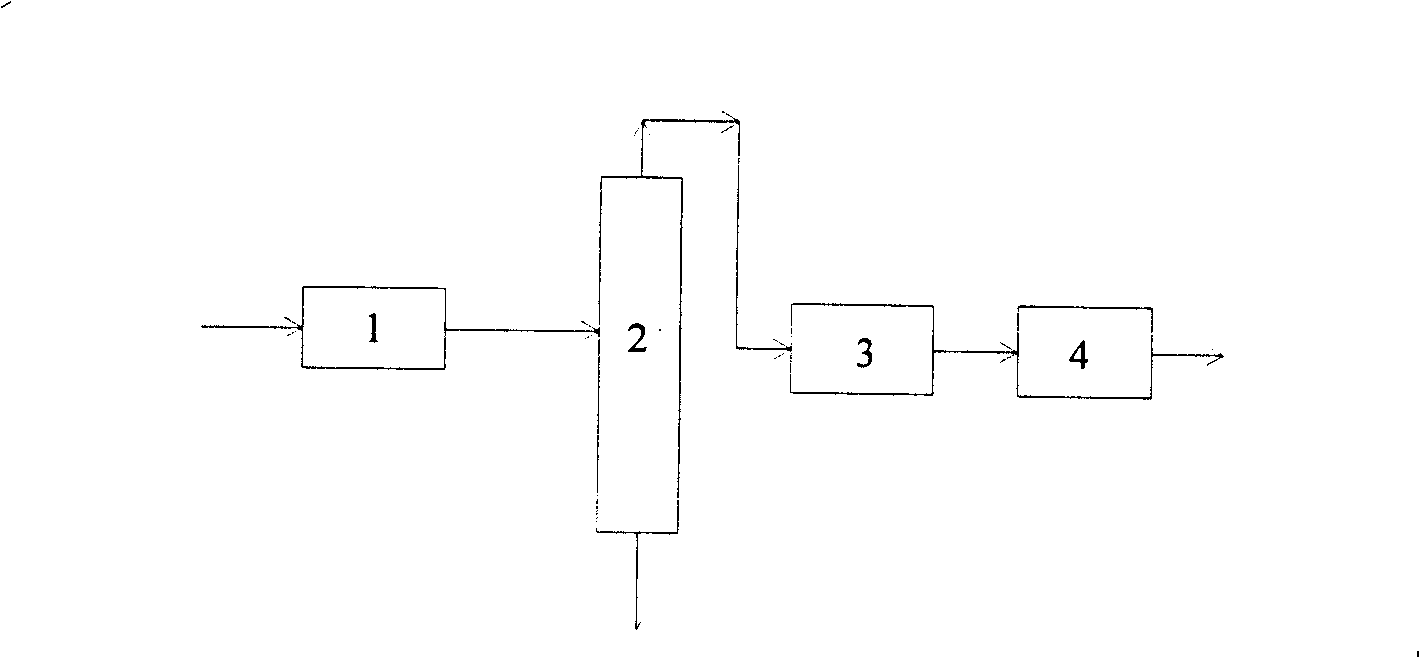

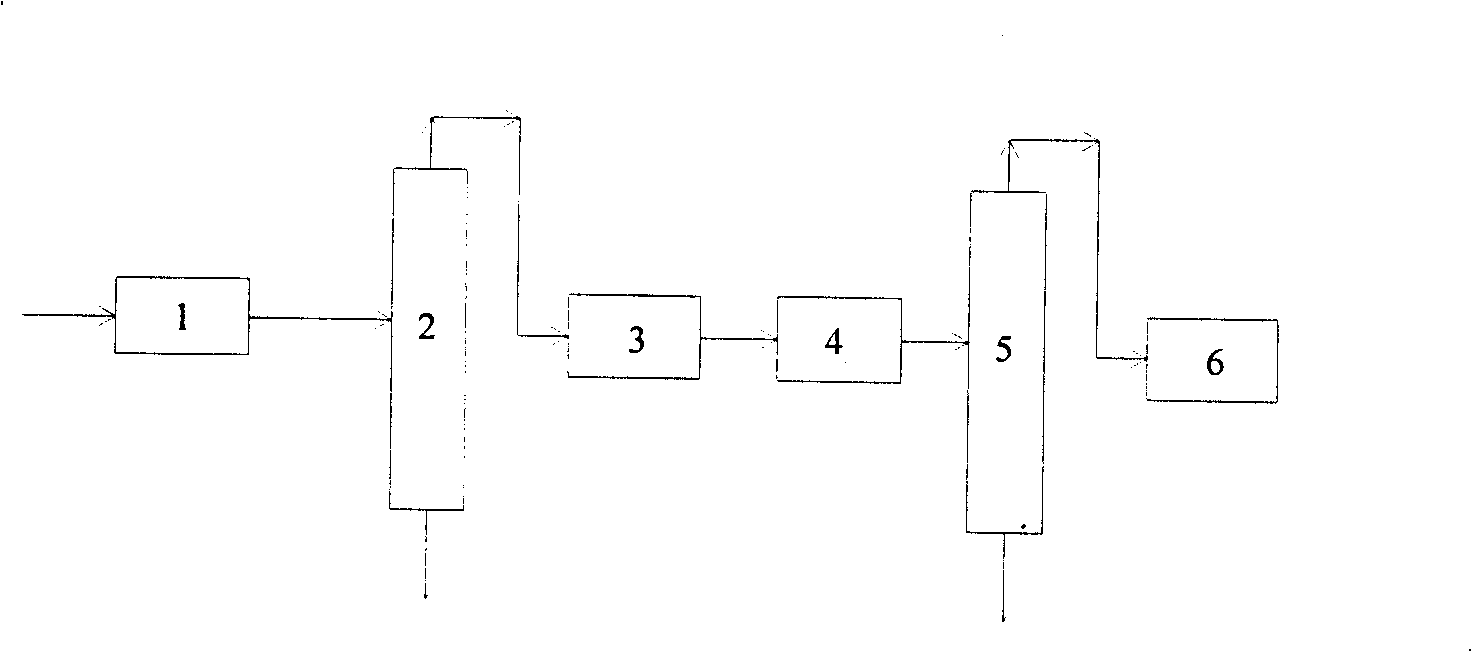

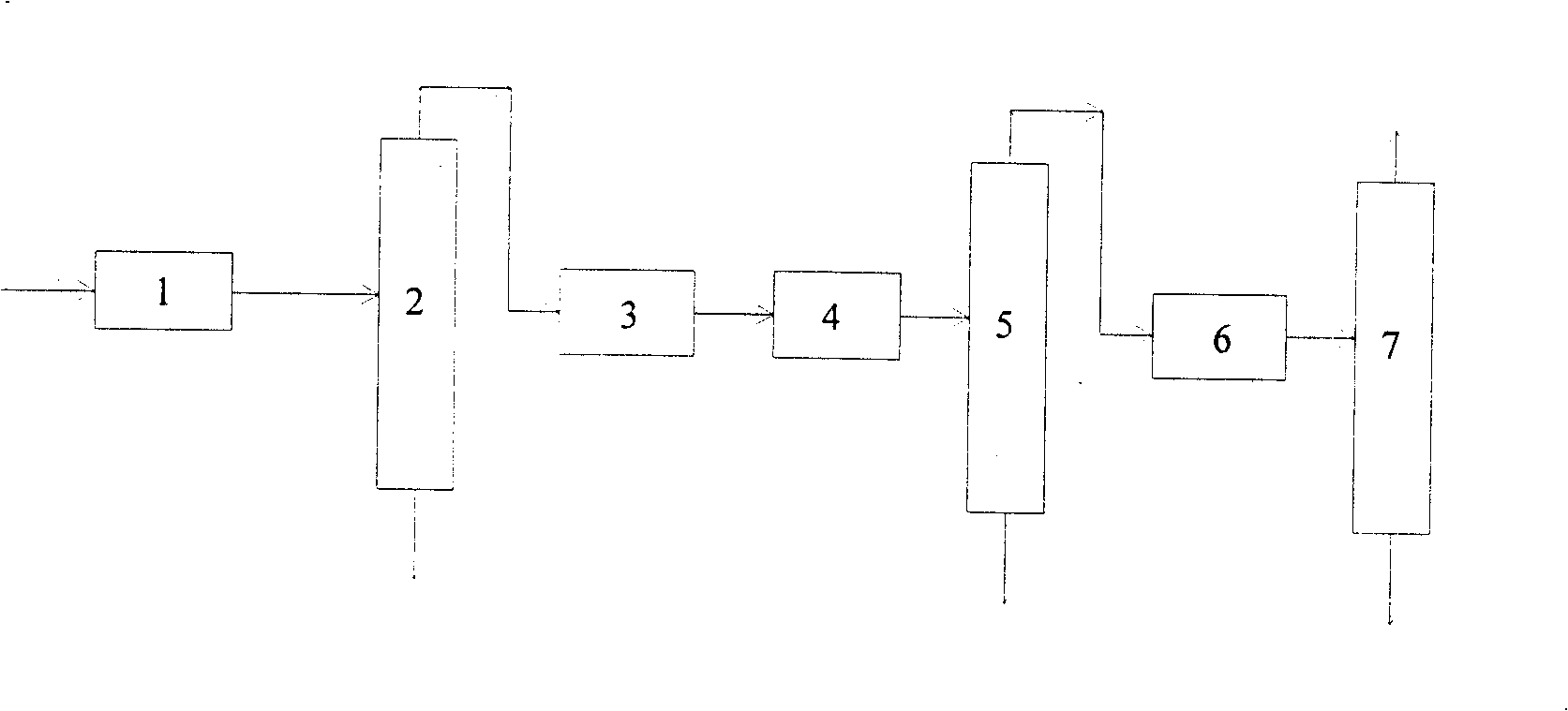

Method used

Image

Examples

Embodiment 1

[0061] (1) Using cracked C5 fraction of Yanshan Petrochemical as raw material, its composition is shown in Table 1 below, and the contents in Table 1 are in weight percent. The above-mentioned materials are sent to a dimerization reactor for dimerization reaction. The dimerization reaction temperature is 80° C., the reaction pressure is 0.5 MPa, and the residence time is 60 minutes.

[0062] (2) The material that the dimerization reactor comes out is sent into the de-dicyclopentadiene tower, extracts the main material of dicyclopentadiene at the tower still, and steams the cracked carbon five fraction b of removing dicyclopentadiene at the top of the tower ; The theoretical plate number of the debicyclopentadiene tower is 20, the reflux ratio is 1, the pressure at the top of the tower is 0.08MPa, the pressure at the bottom of the tower is 0.10MPa, the temperature at the top of the tower is 30°C, the temperature at the bottom of the tower is 95°C, and the feed The location is o...

Embodiment 2

[0070] Dimerization, dedicyclopentadiene removal, selective hydrogenation and olefin conversion in this example are the same as in Example 1, except that no etherification step is included. In the olefin conversion step, based on the cracked C5 fraction, the yield of conversion to ethylene is 11%, and the yield of conversion to propylene is 22%.

Embodiment 3

[0072] This example is basically the same as Example 1, the difference is that after the conversion of olefins, the C5 material is separated by ordinary rectification method and then fully hydrogenated. The catalyst is the Chinese patent ZL02104202.0 of Beijing Research Institute of Chemical Industry For the catalyst of Example 1, the reaction temperature is 60°C, the reaction pressure is 1.0MPa, the molar ratio of hydrogen to olefin is 1.5:1, and the liquid volume space velocity is 1.0h -1 . The fully hydrogenated feed contained 95% by weight of n-pentane.

[0073] Table 1

[0074]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com