Latching micro magnetic relay packages and methods of packaging

A technology of components and devices, applied in the field of miniature magnetic latching relays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

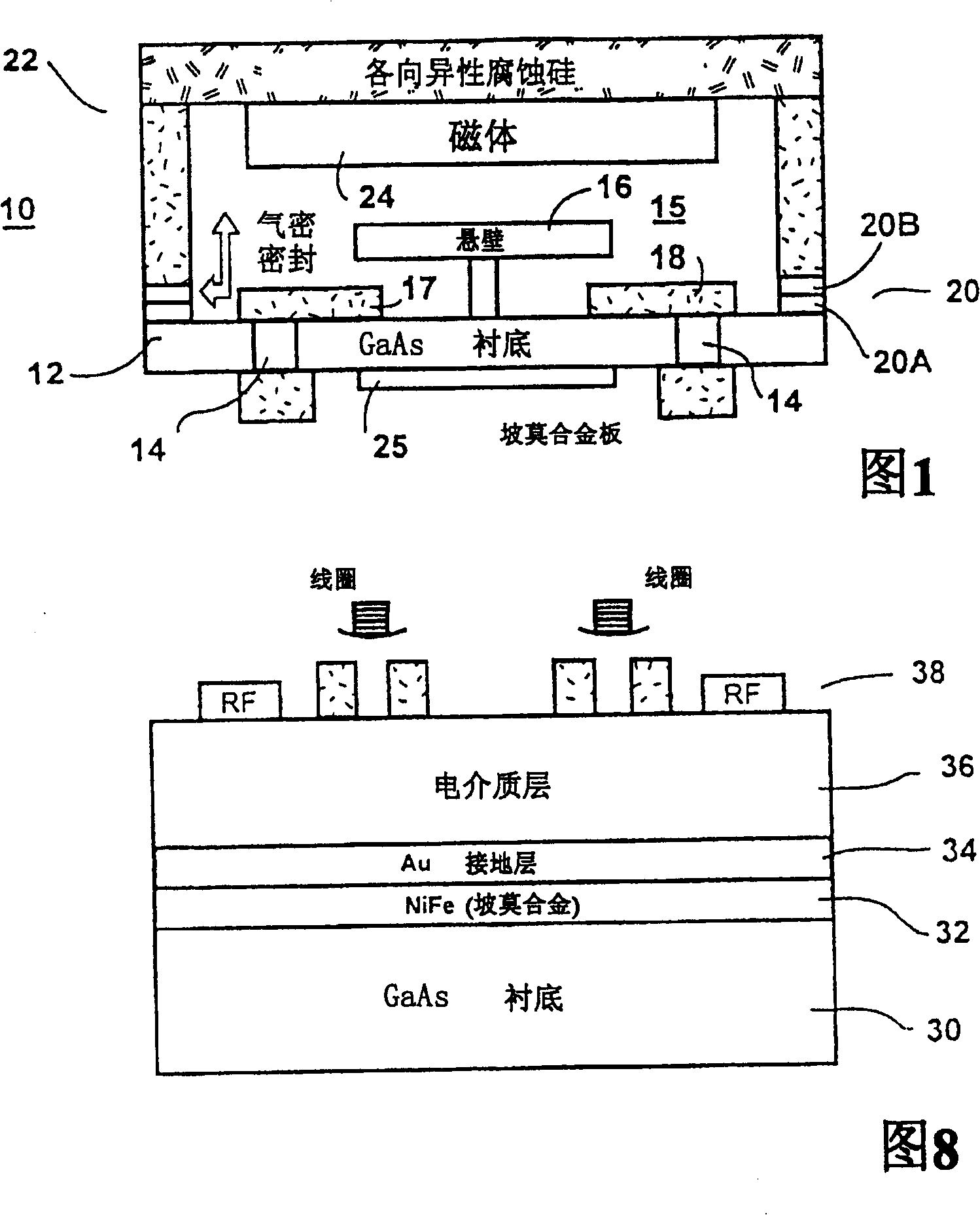

[0025] Referring now to FIG. 1, there is illustrated a wafer-scale assembly 10 of a miniature magnetic latching relay or other MEMS structure incorporating a magnet or other thermally sensitive element. As described below, a major advantage of assembly 10 is that it can be assembled using solder ingots and cryogenic equipment. It is desirable to use cryogenic devices because magnets incorporated into MEMS structures can be easily damaged by too much heat.

[0026] As will be apparent from the following discussion, assembly 10 can be fabricated in a wafer format without requiring the MEMS devices to be individually assembled into a single assembly. In conjunction with the description of the structures above, typically multiple MEMS devices are formed simultaneously on a single wafer. Labor costs can be high if the wafer must be separated into individual MEMS devices and each individual device assembled separately.

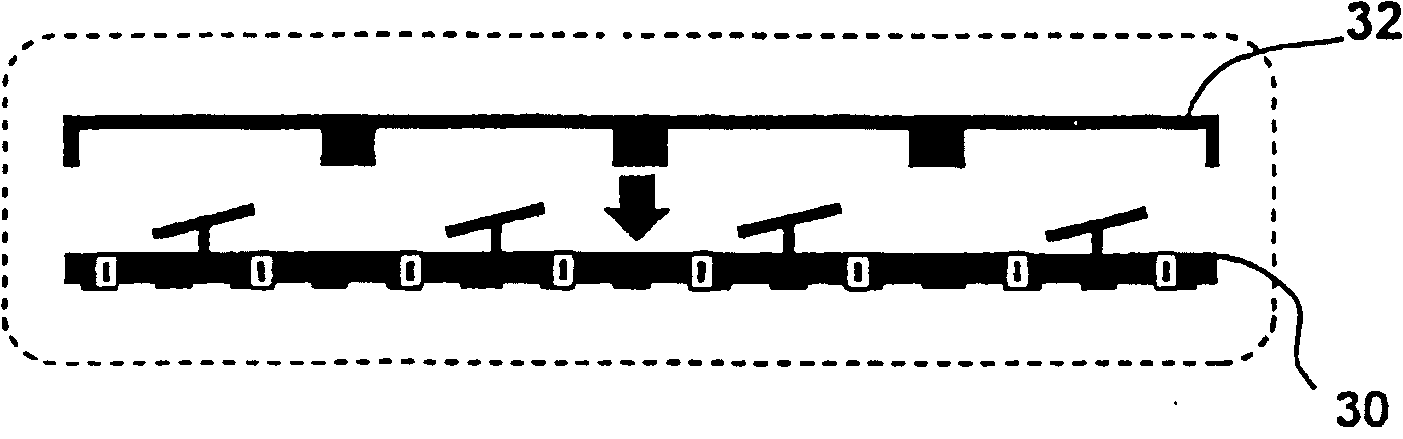

[0027] In this particular embodiment, a gallium arsenide sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com